How to Stop Getting Wrong Products When Buying Building Materials from China

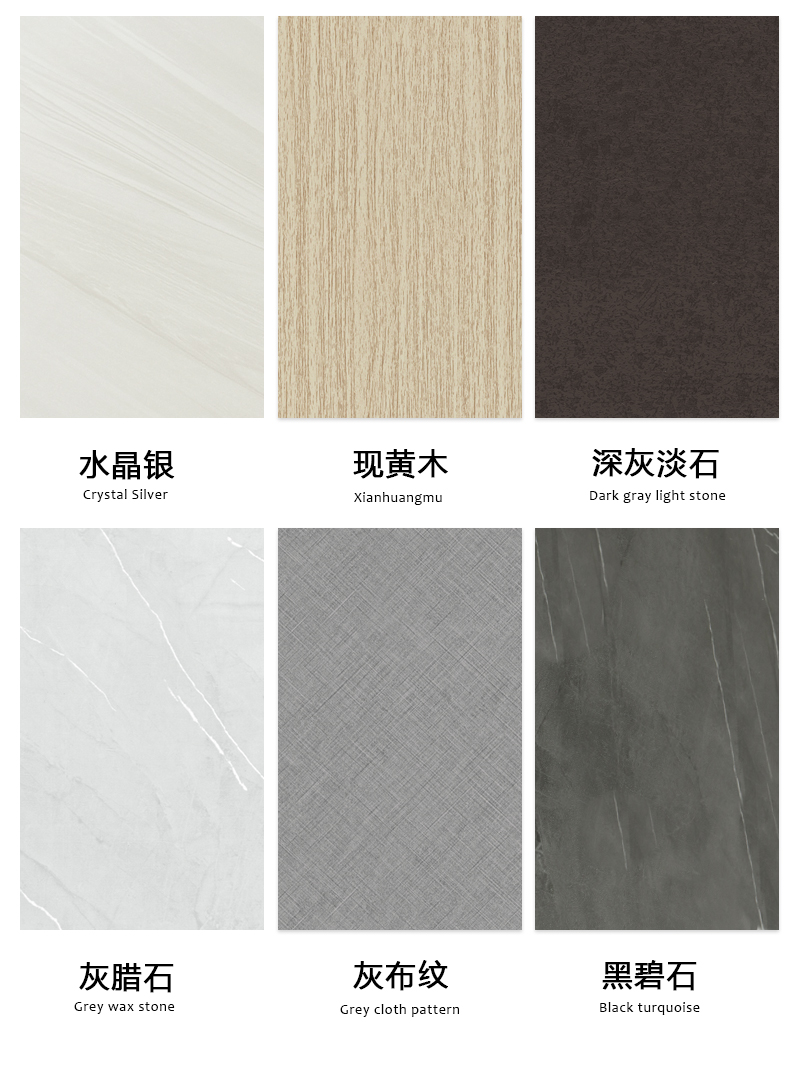

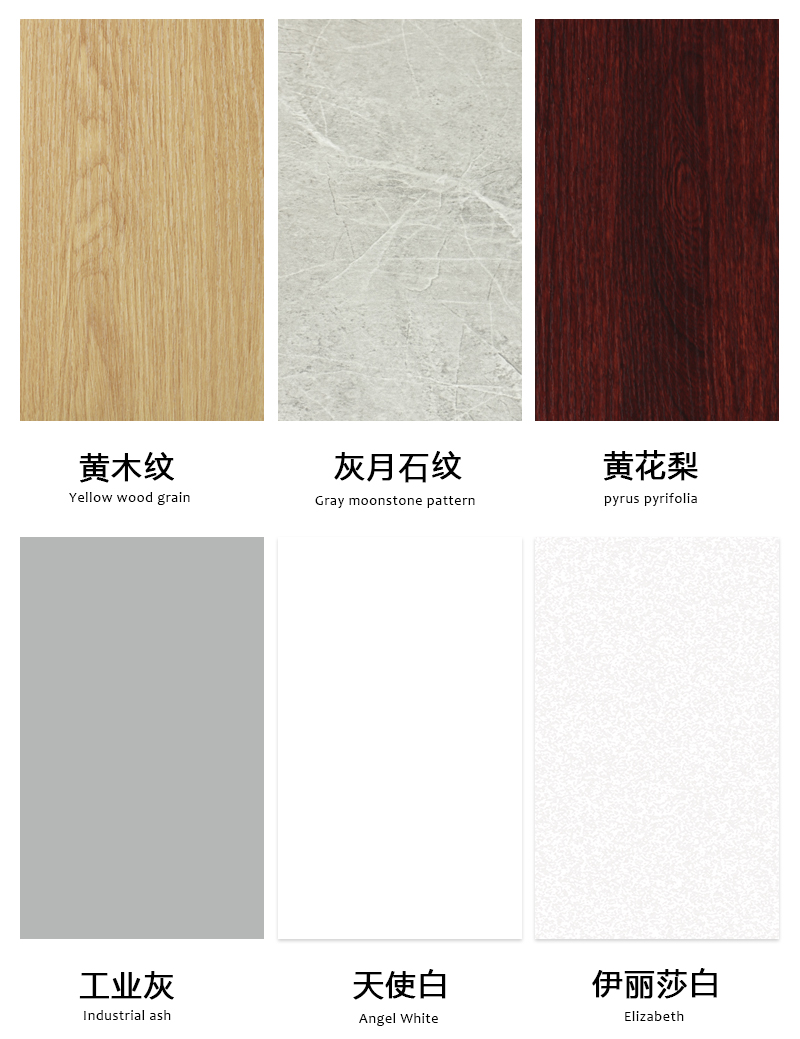

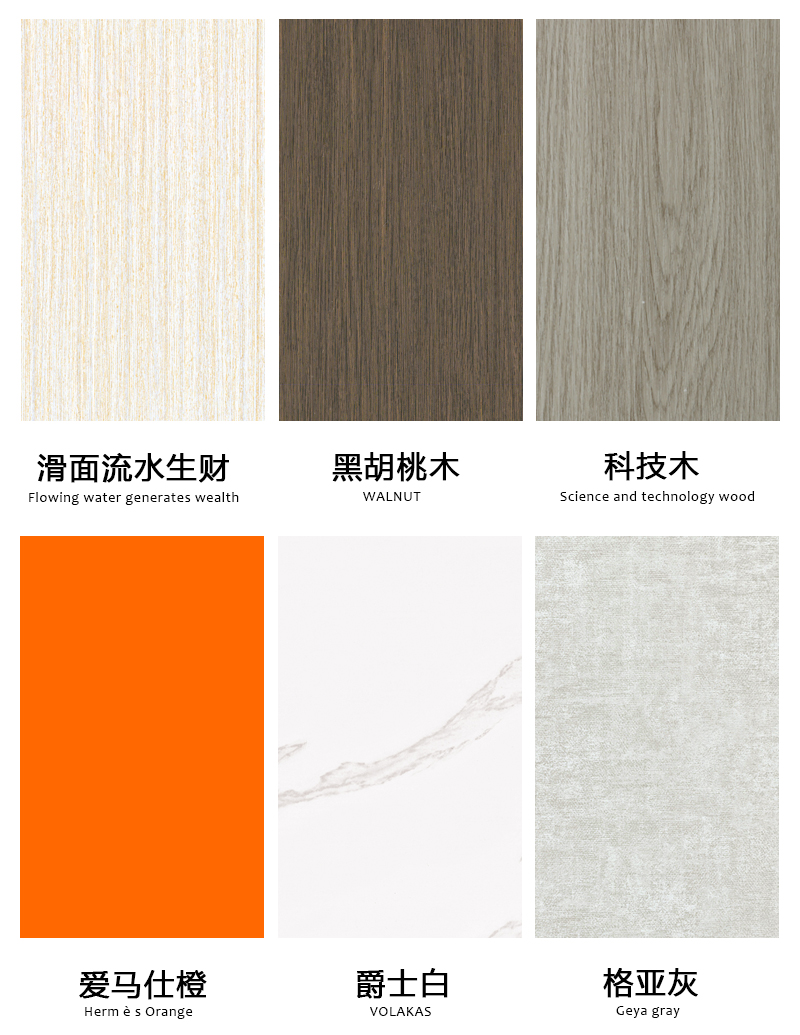

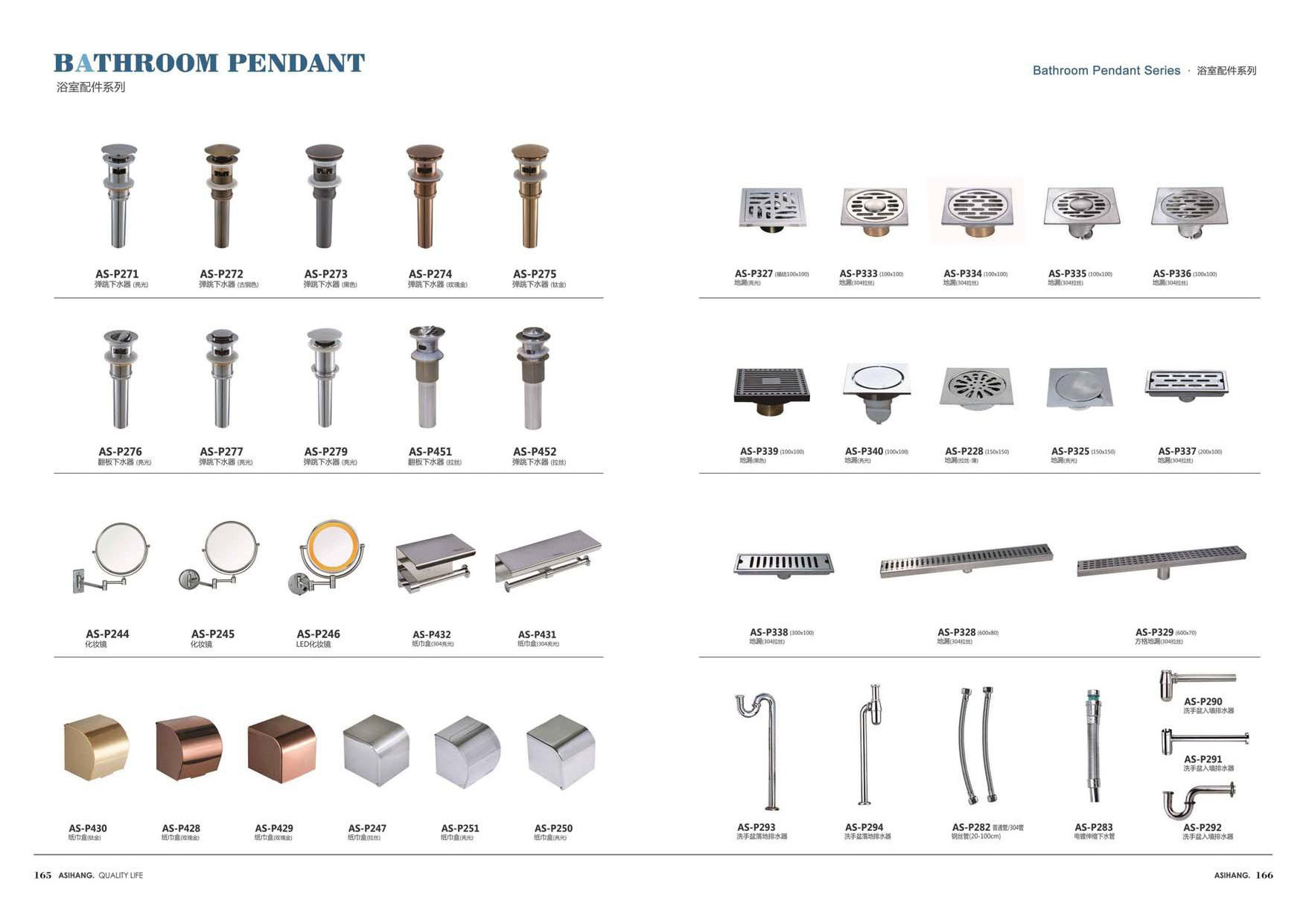

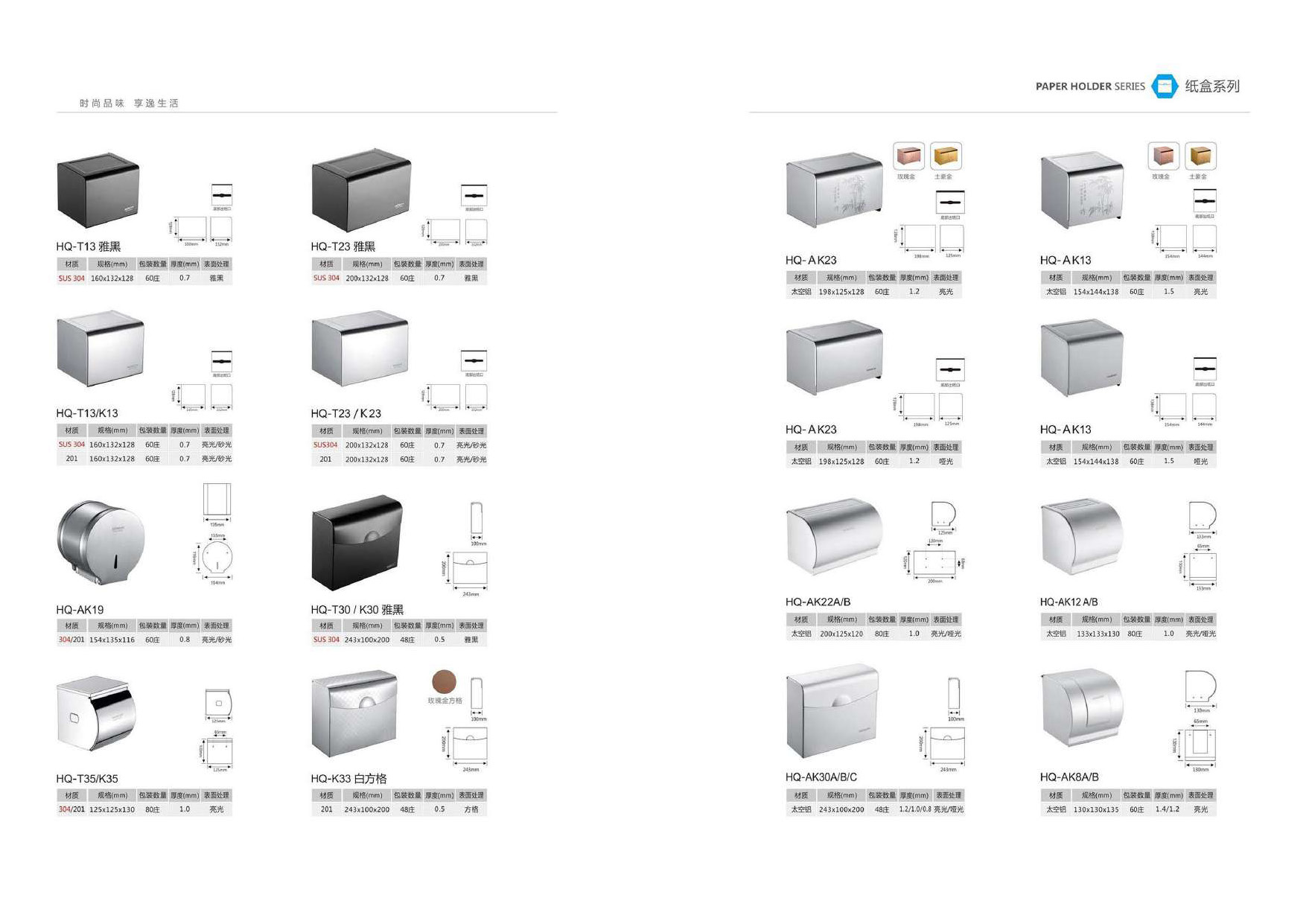

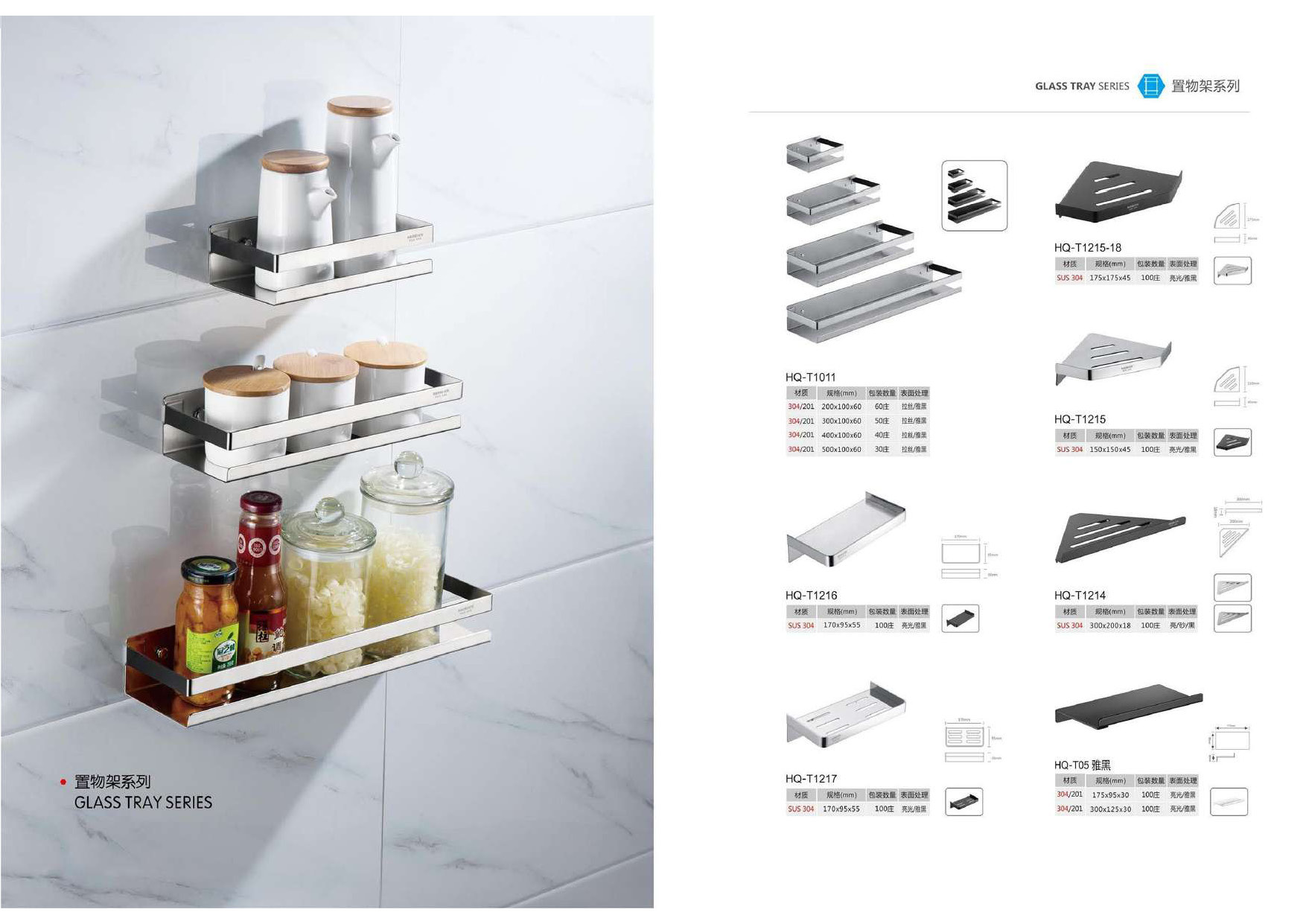

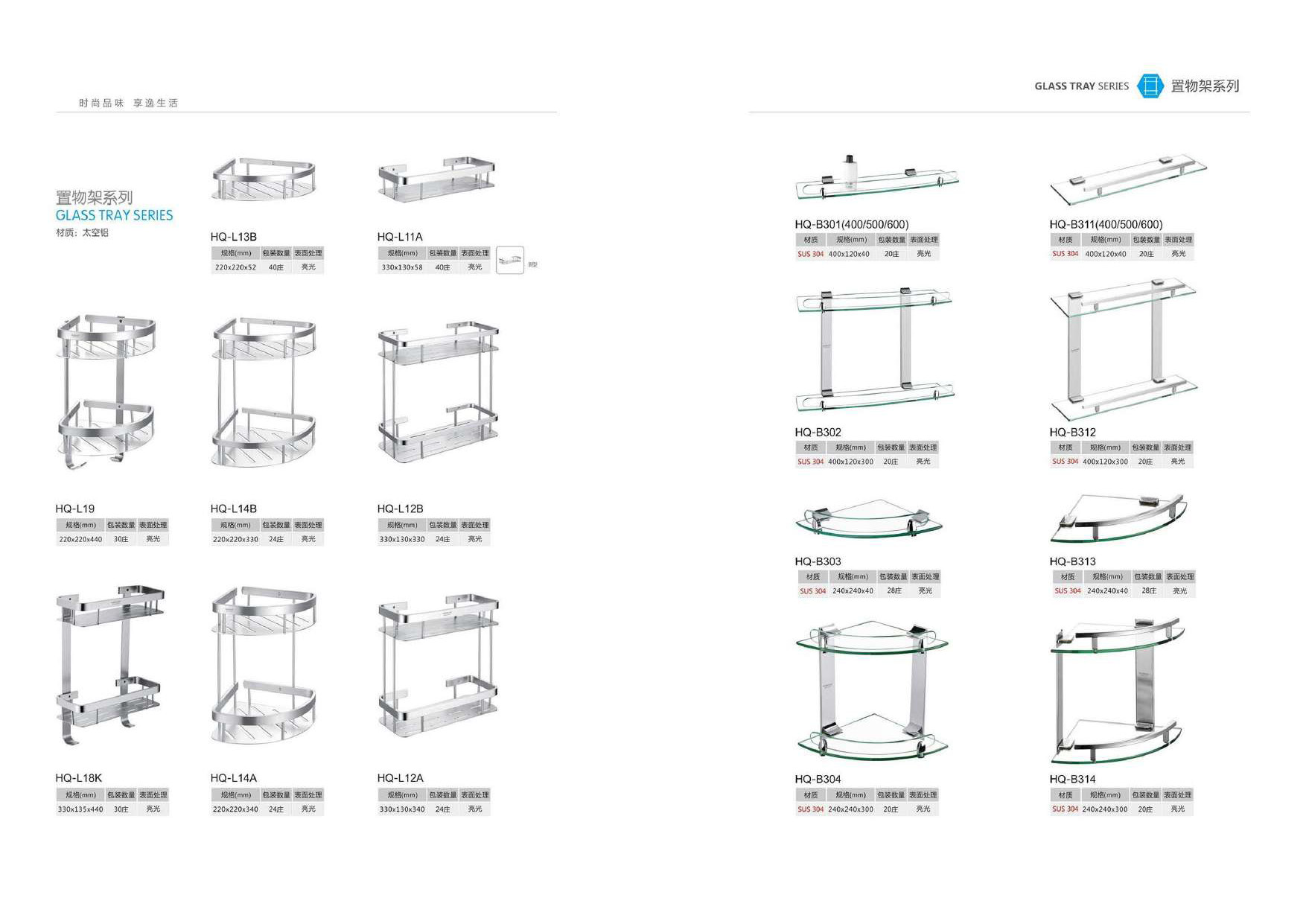

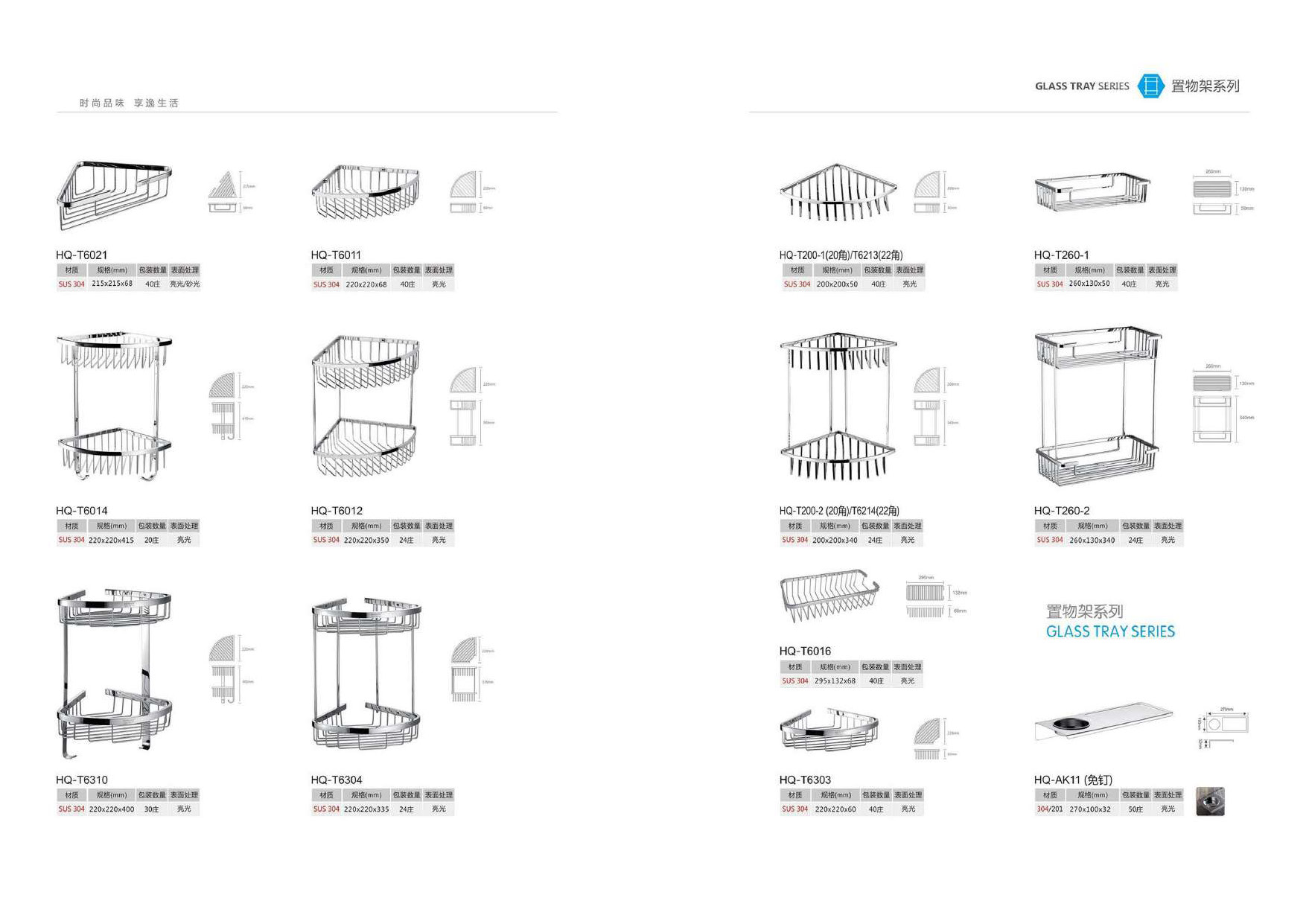

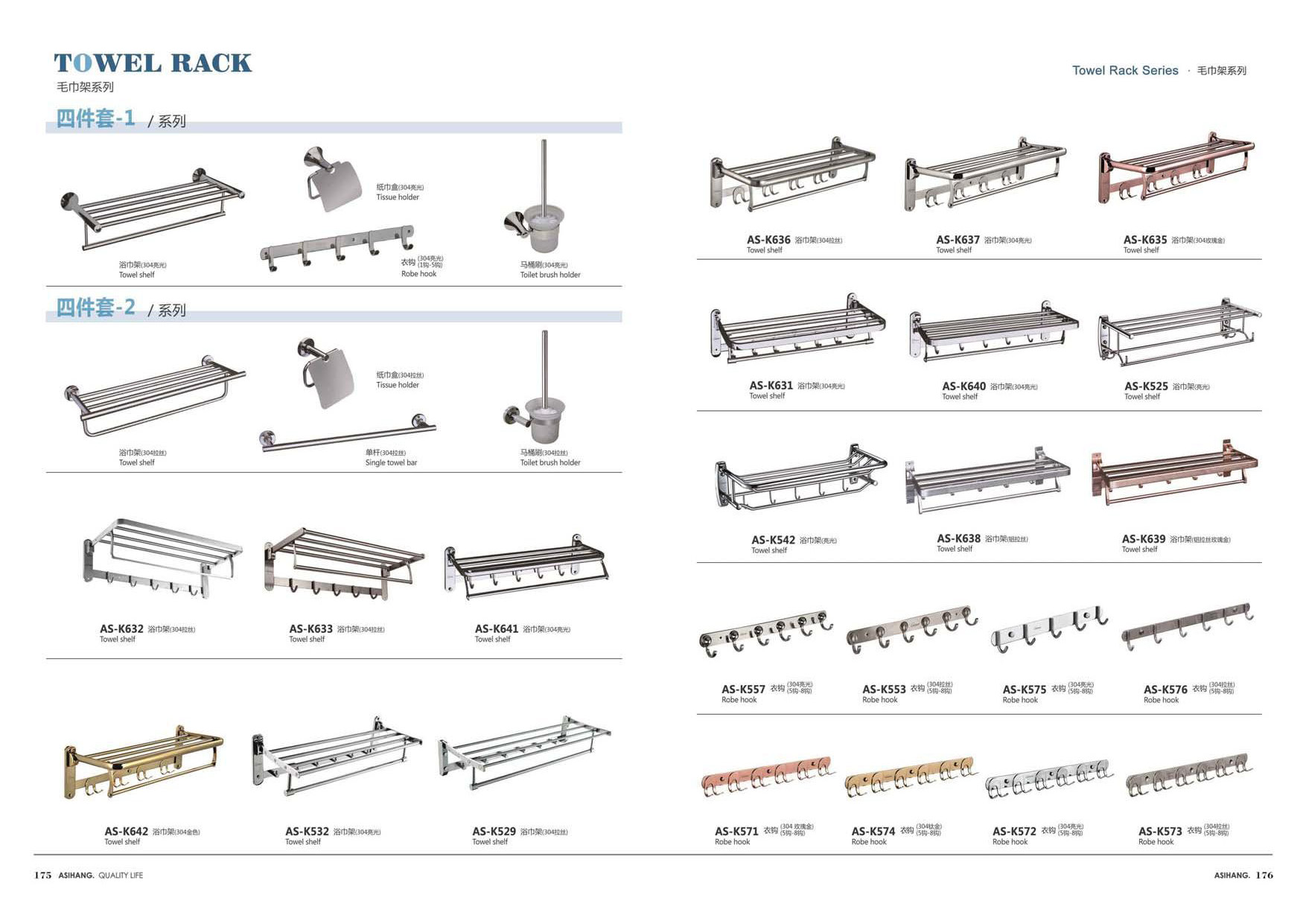

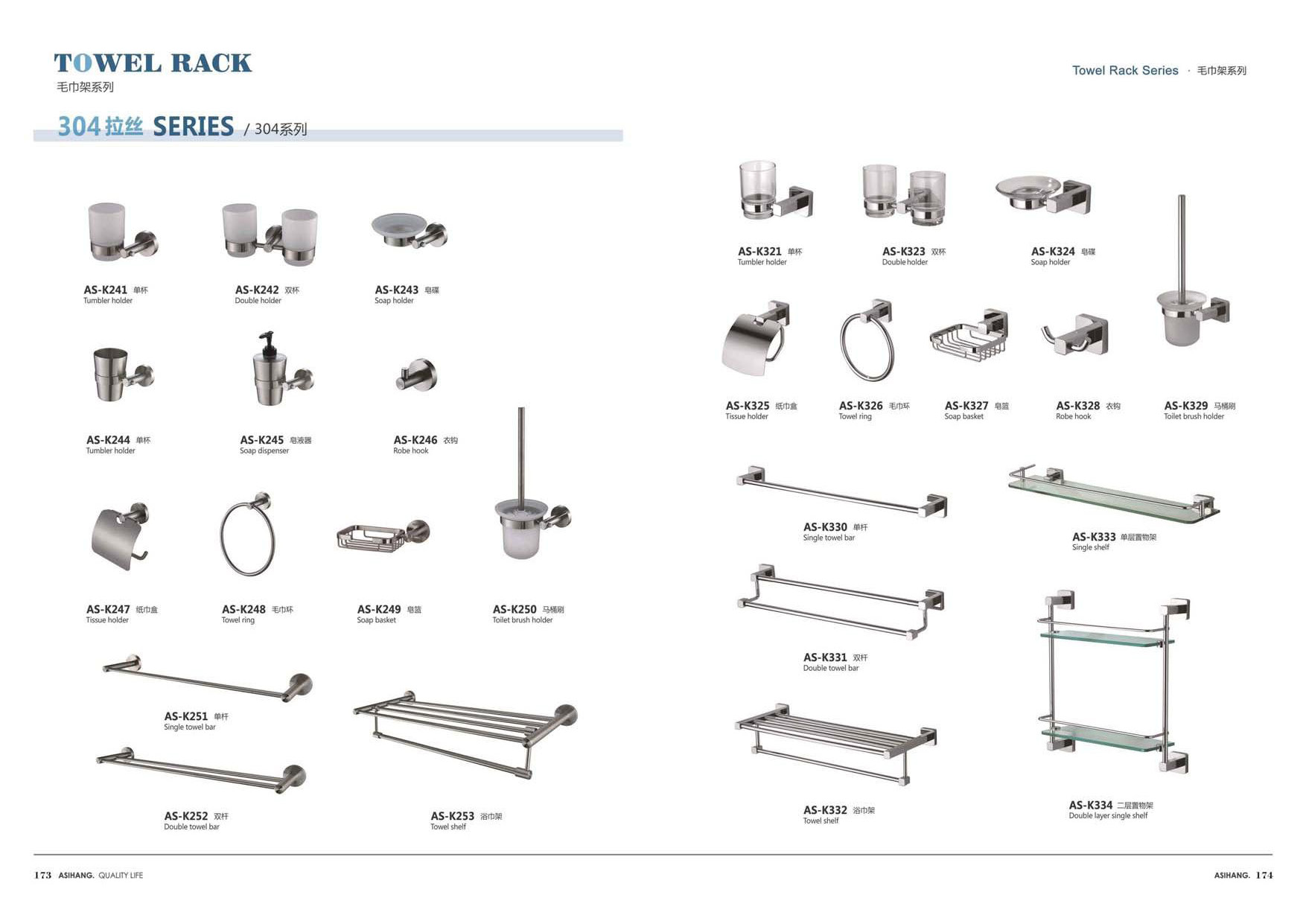

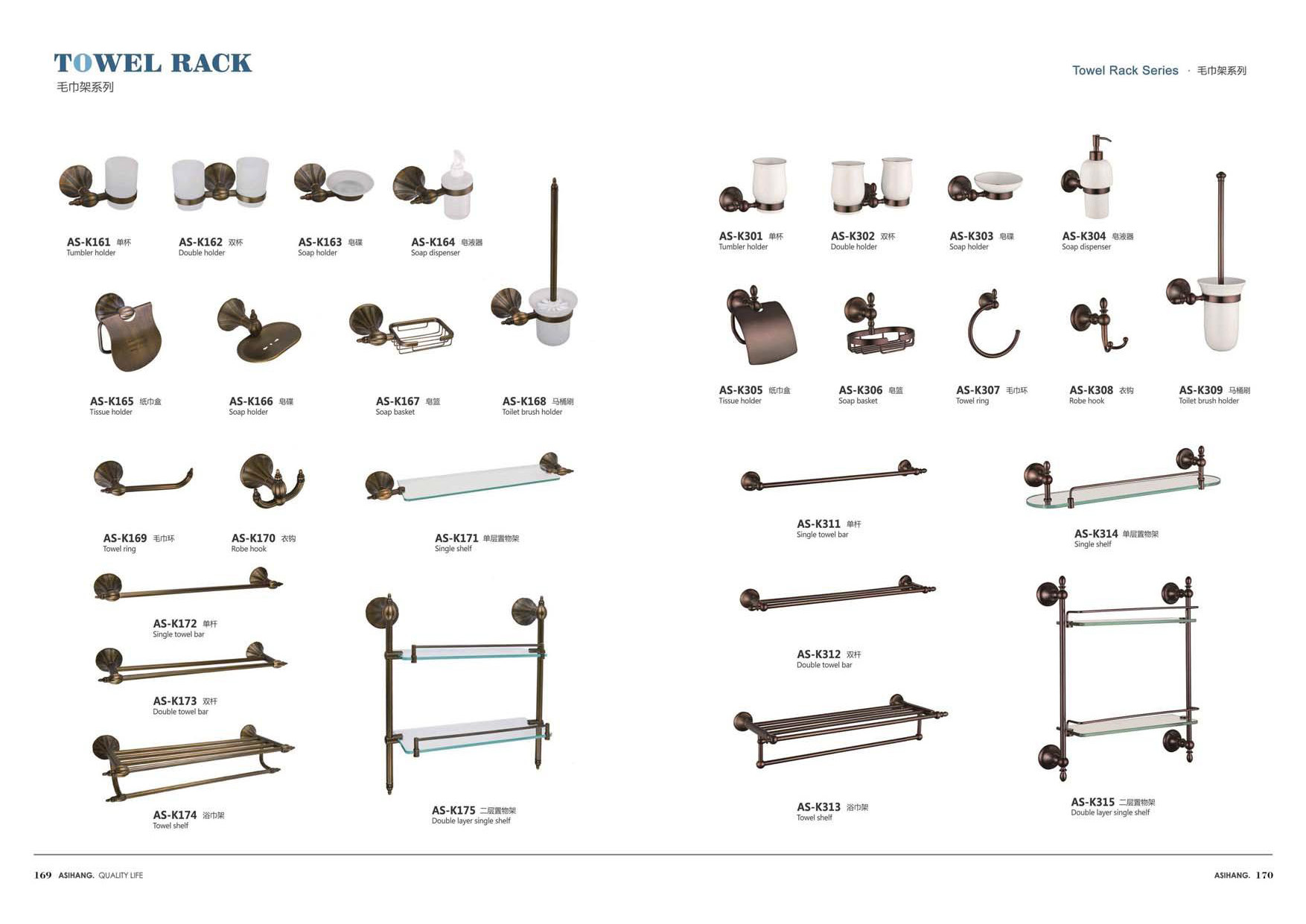

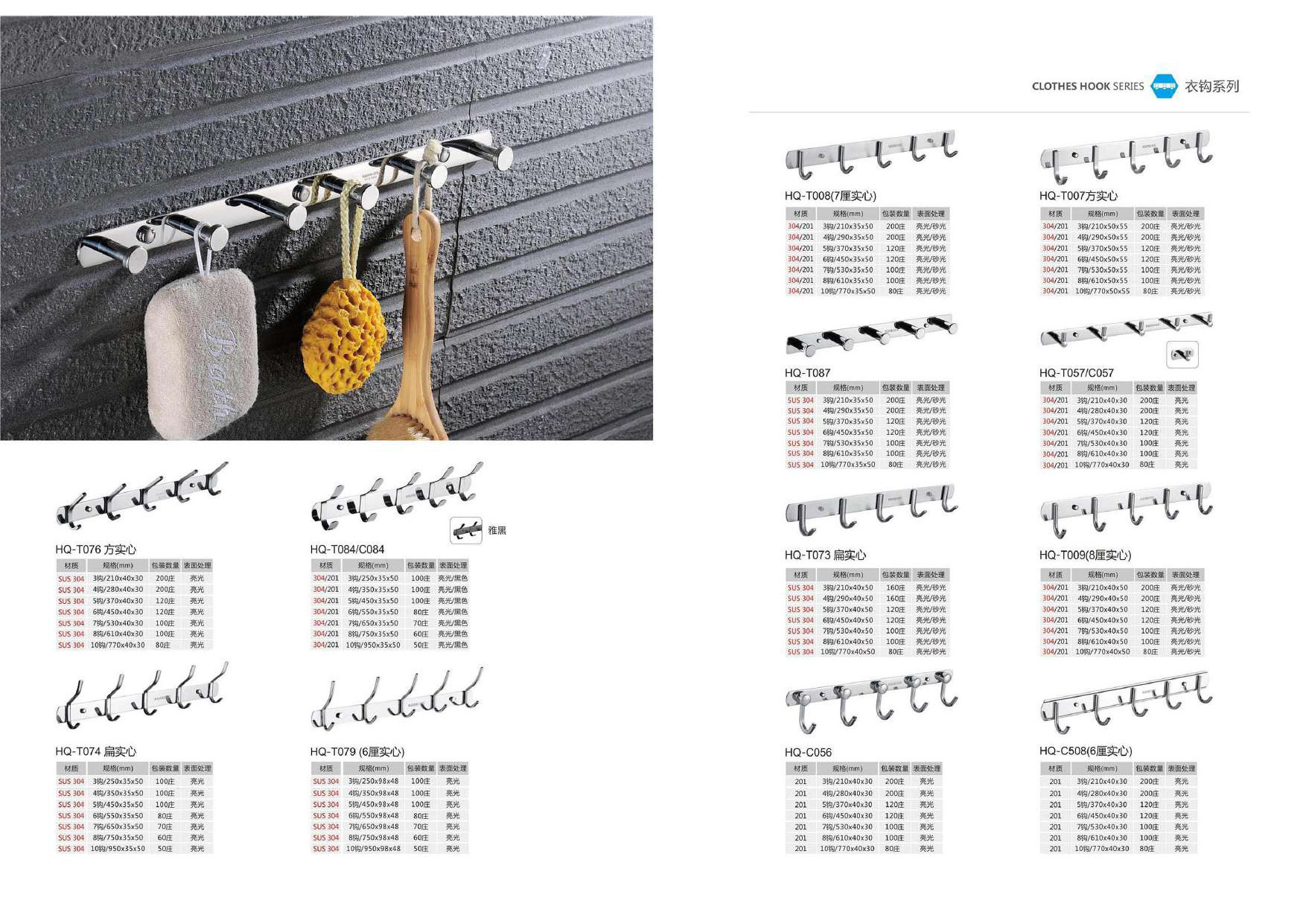

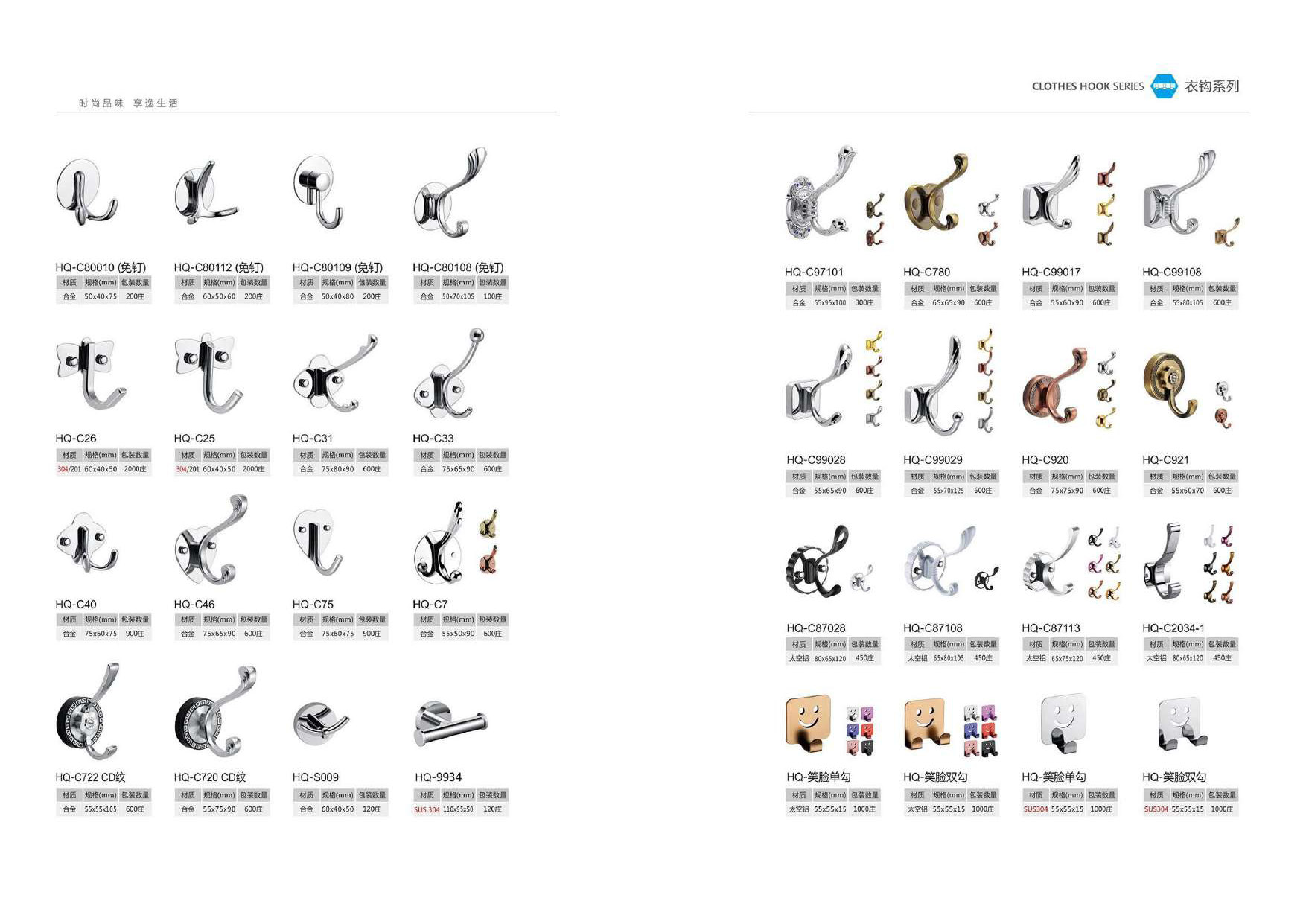

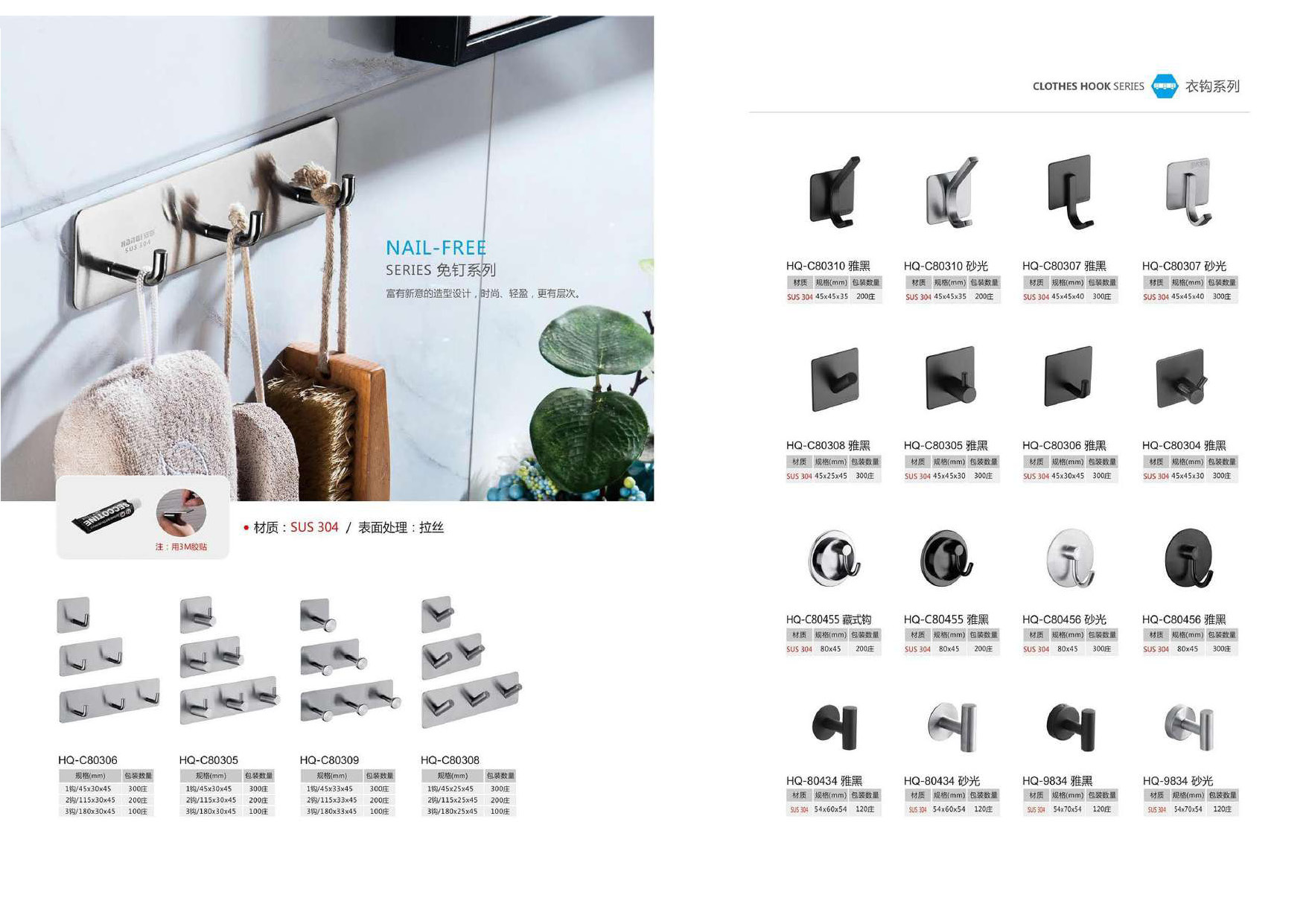

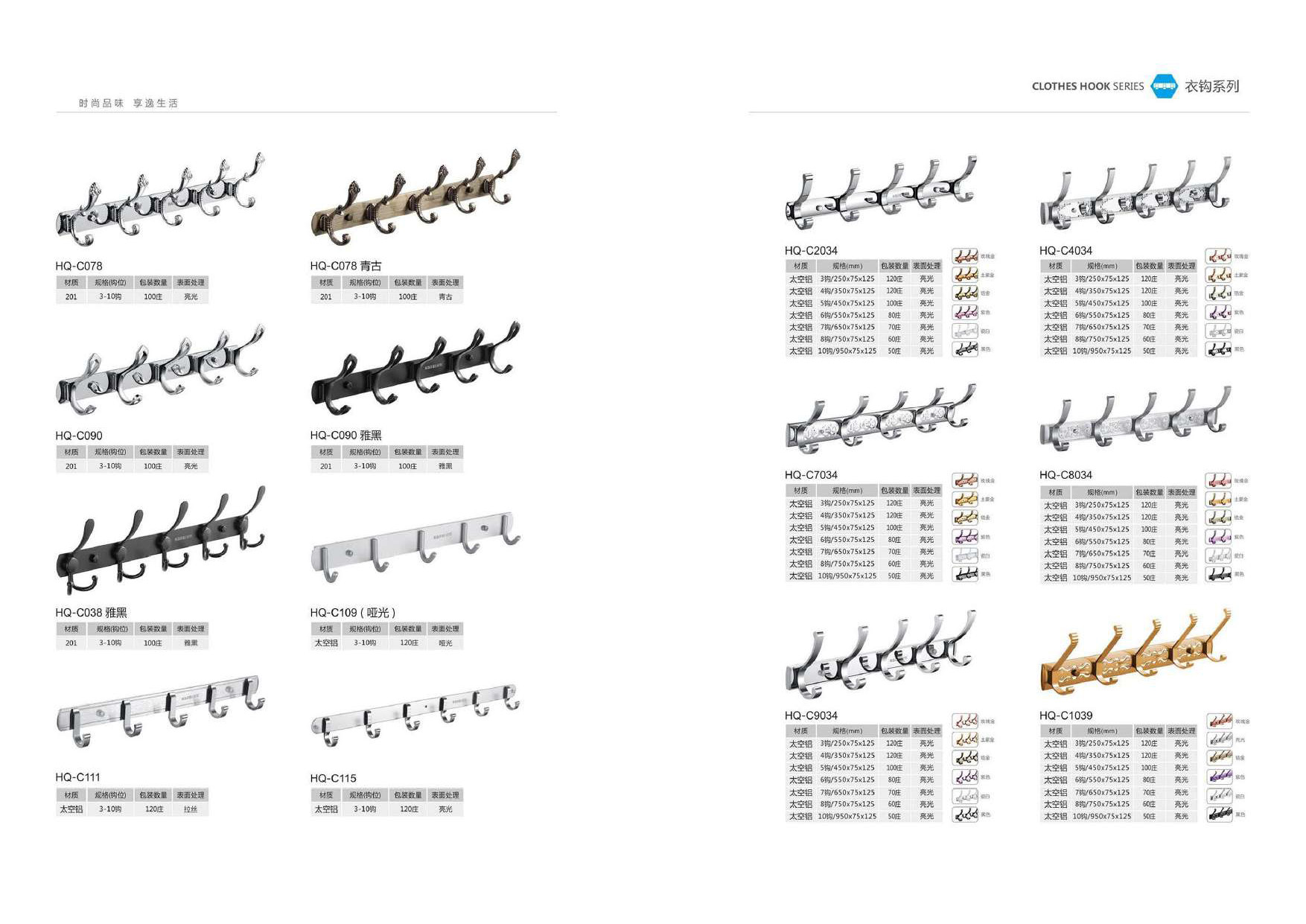

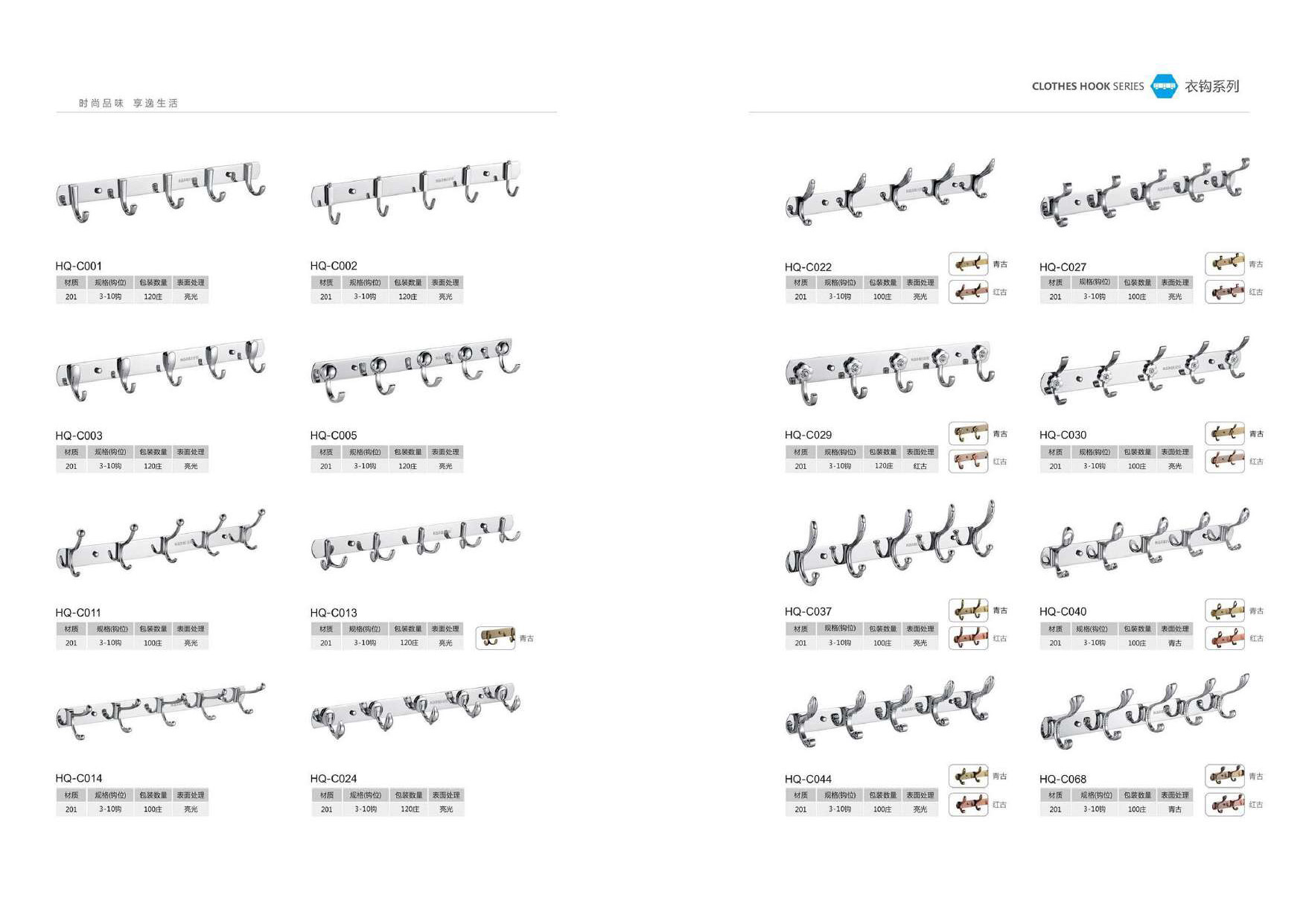

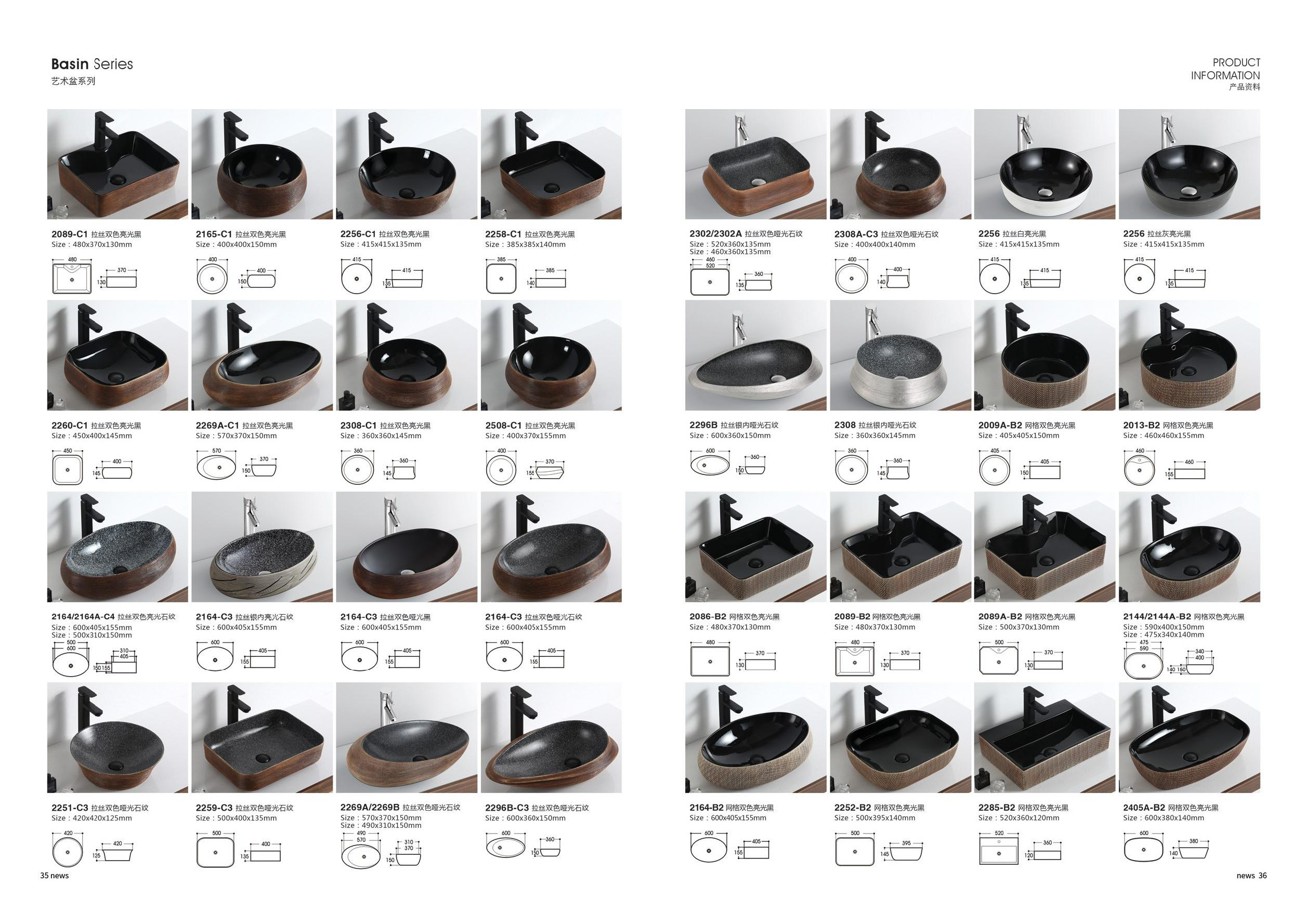

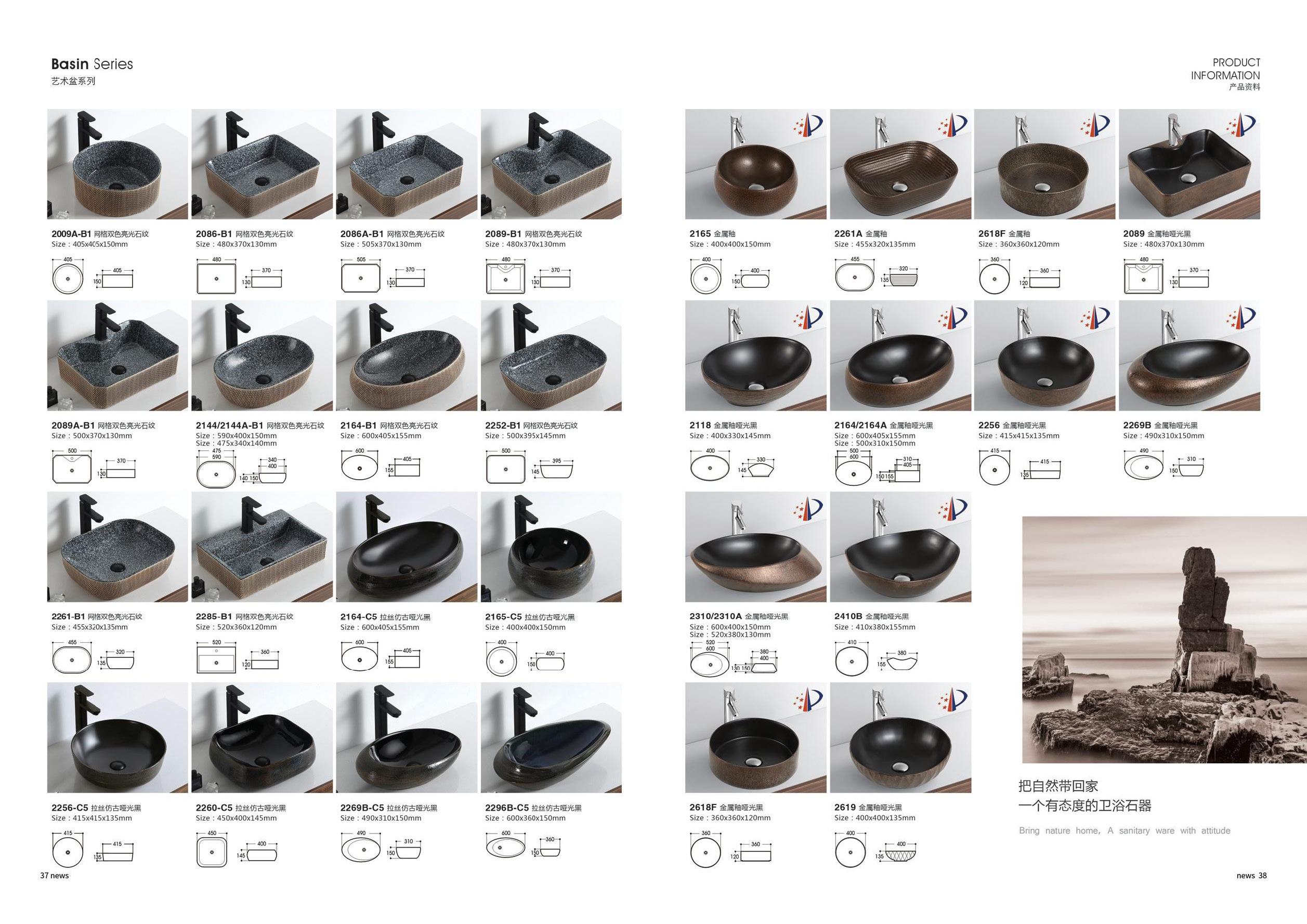

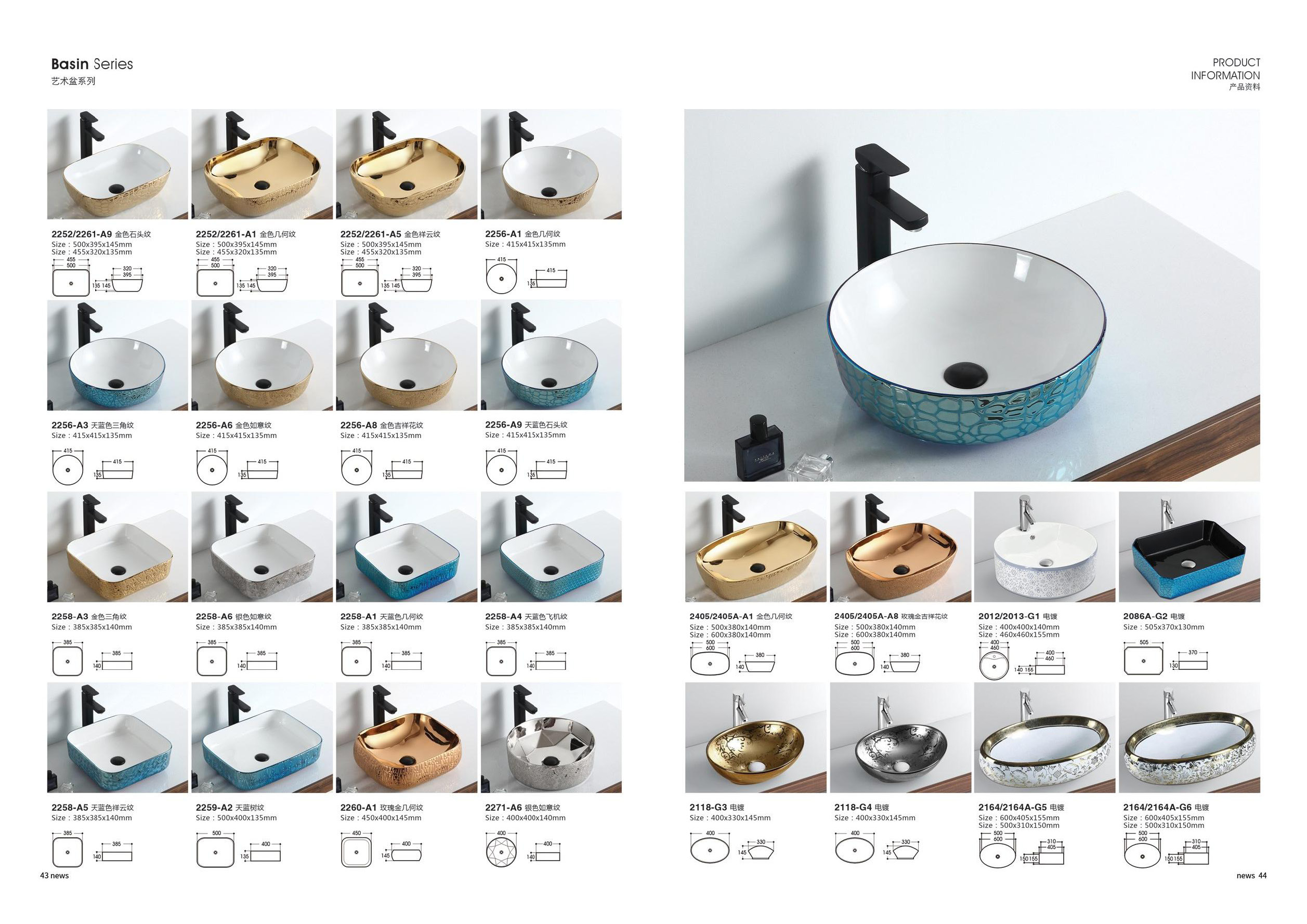

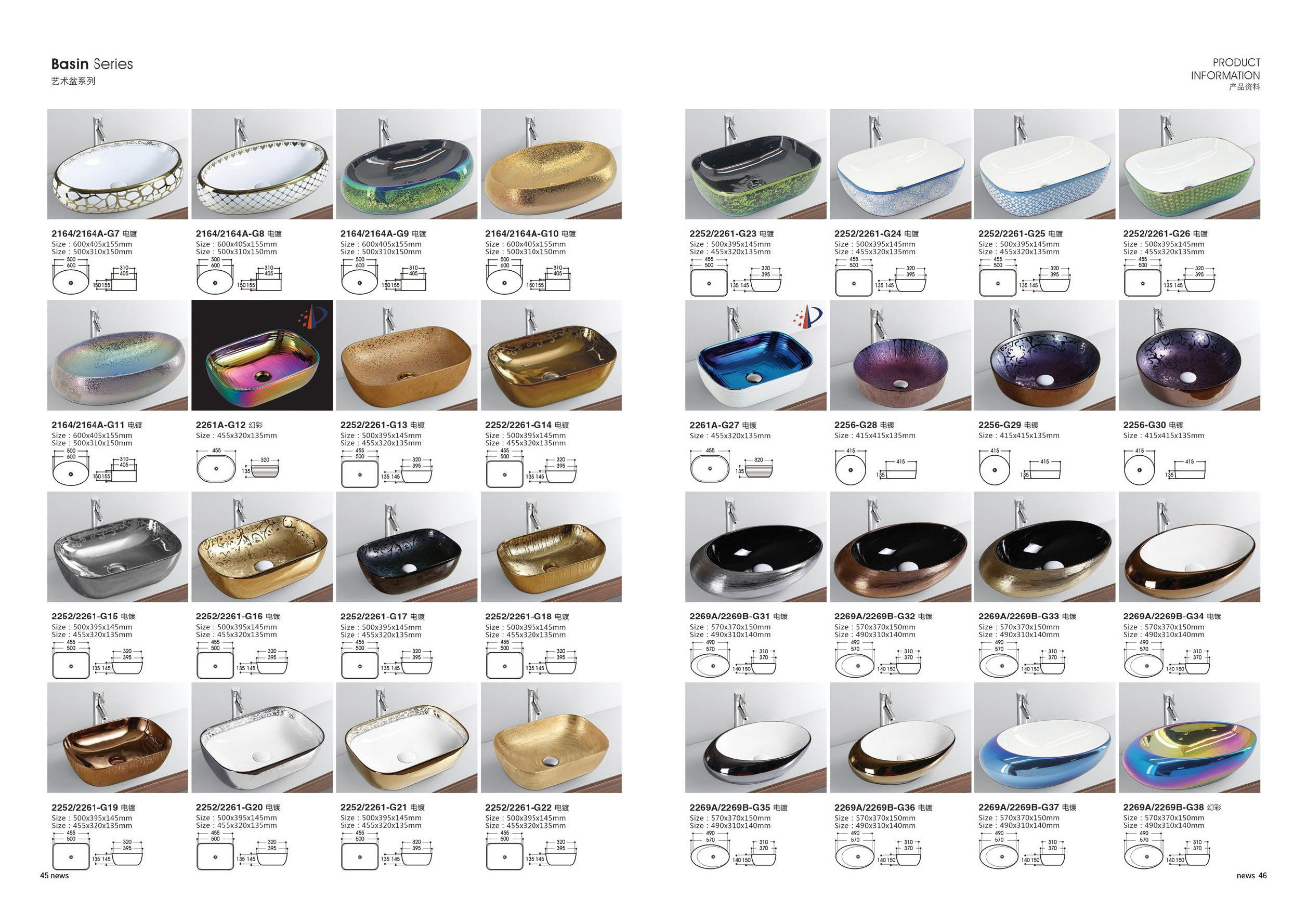

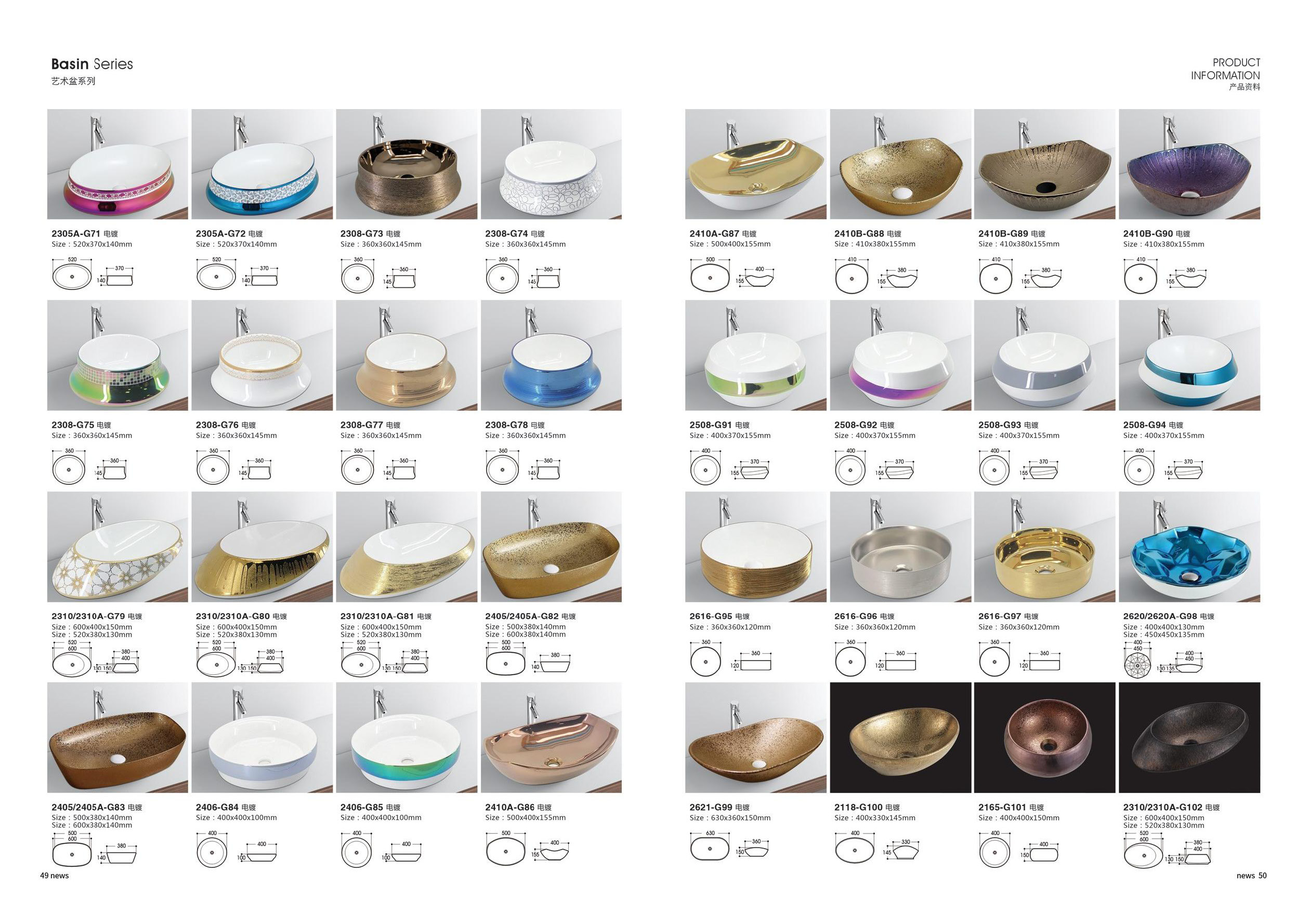

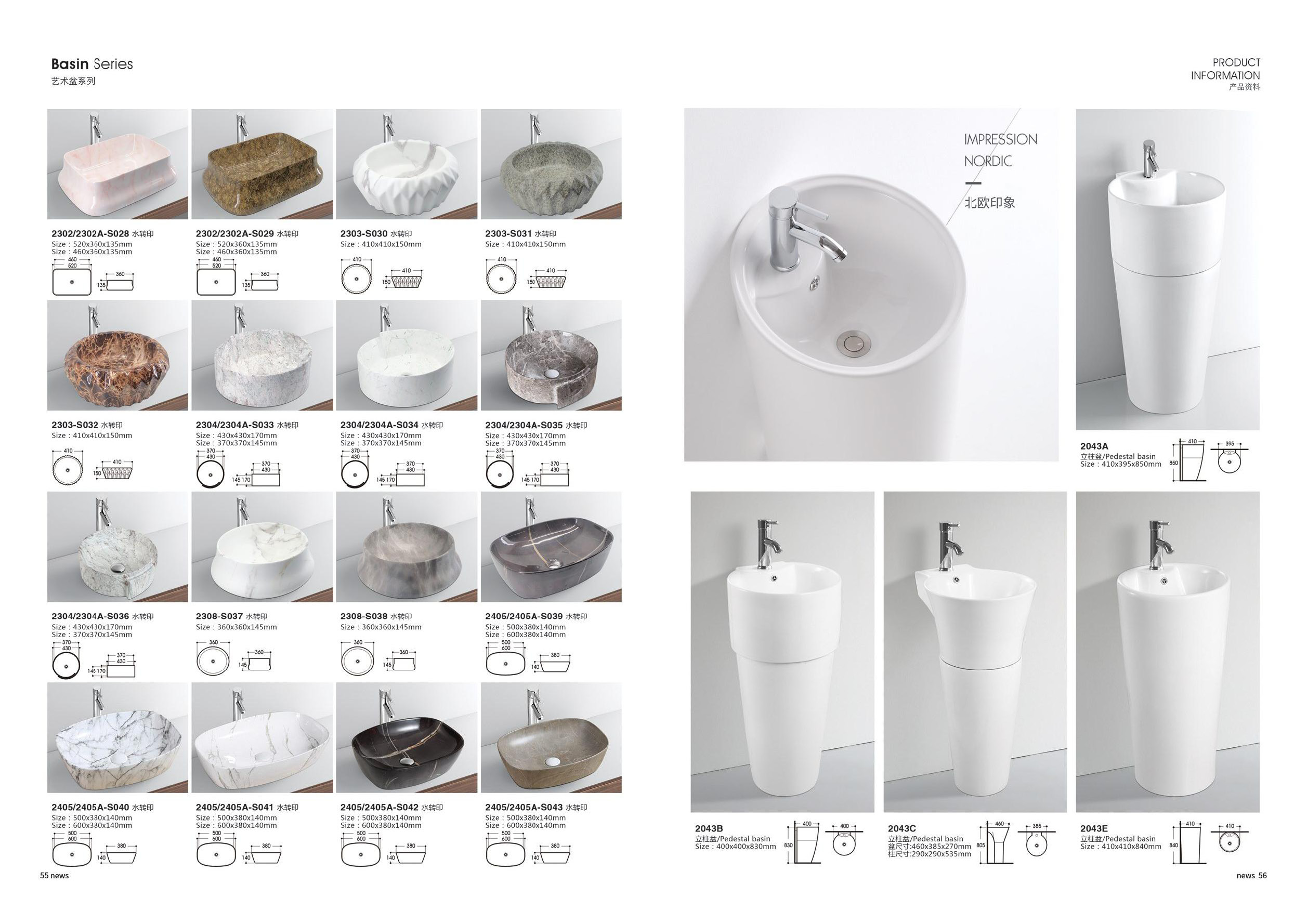

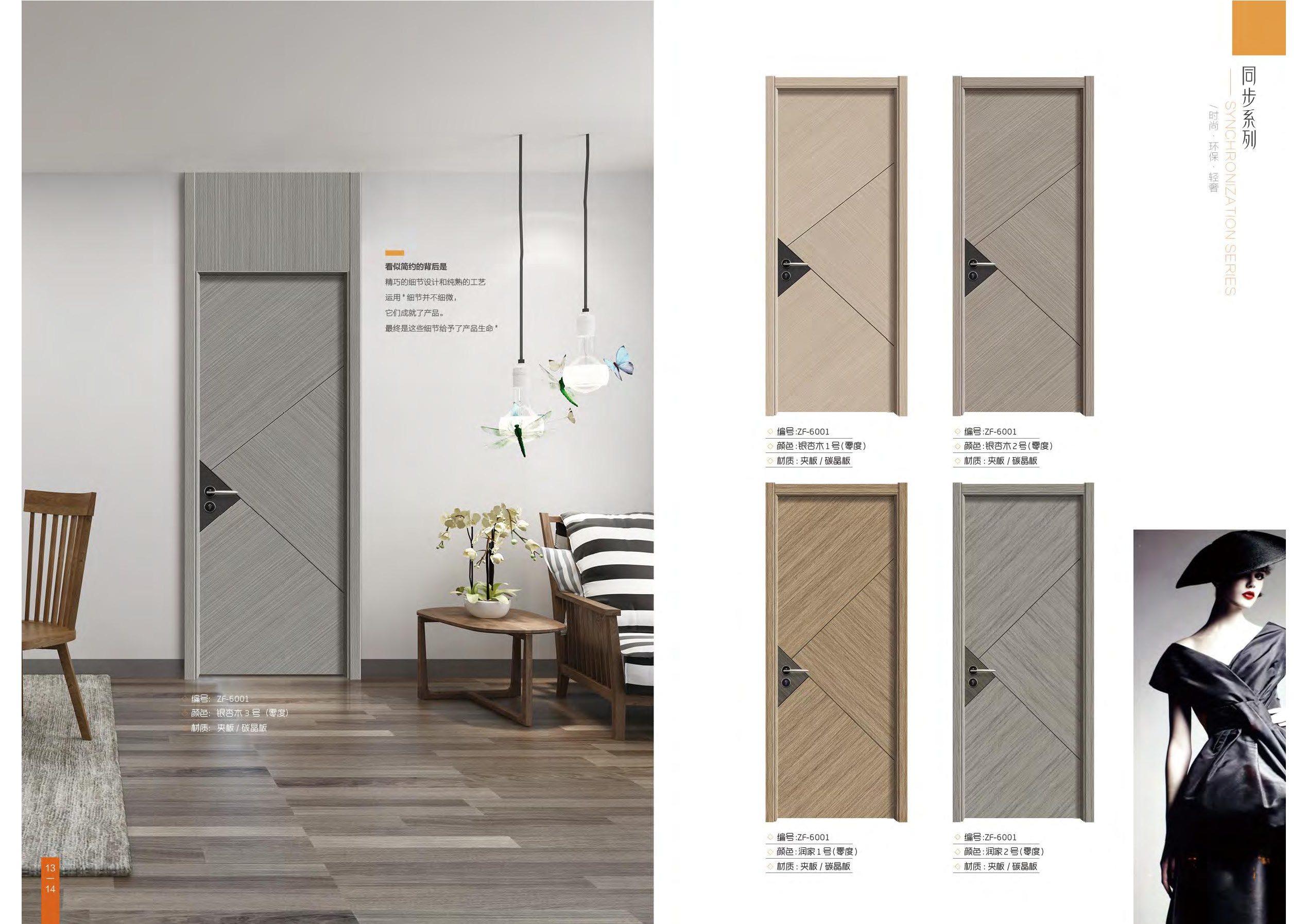

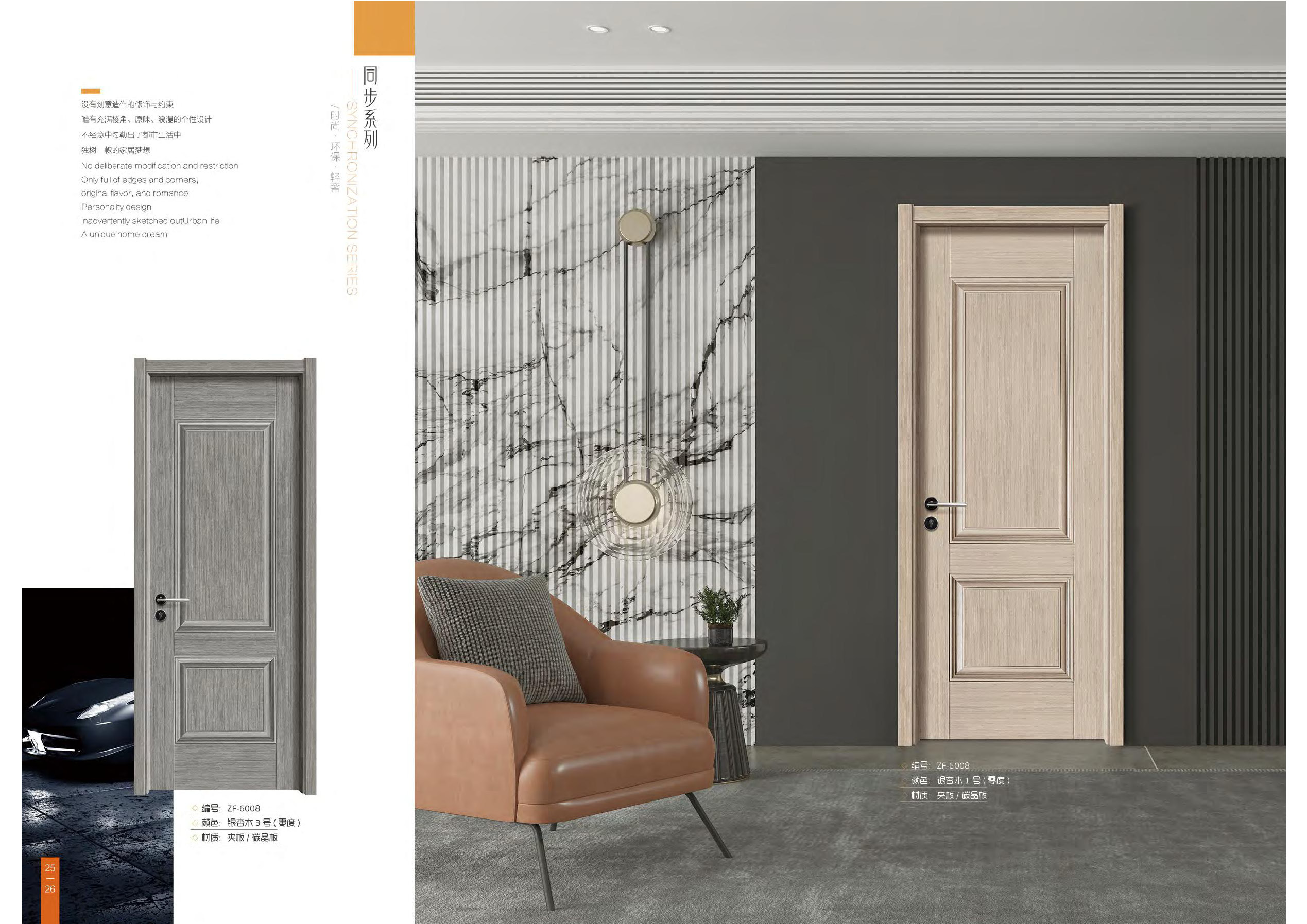

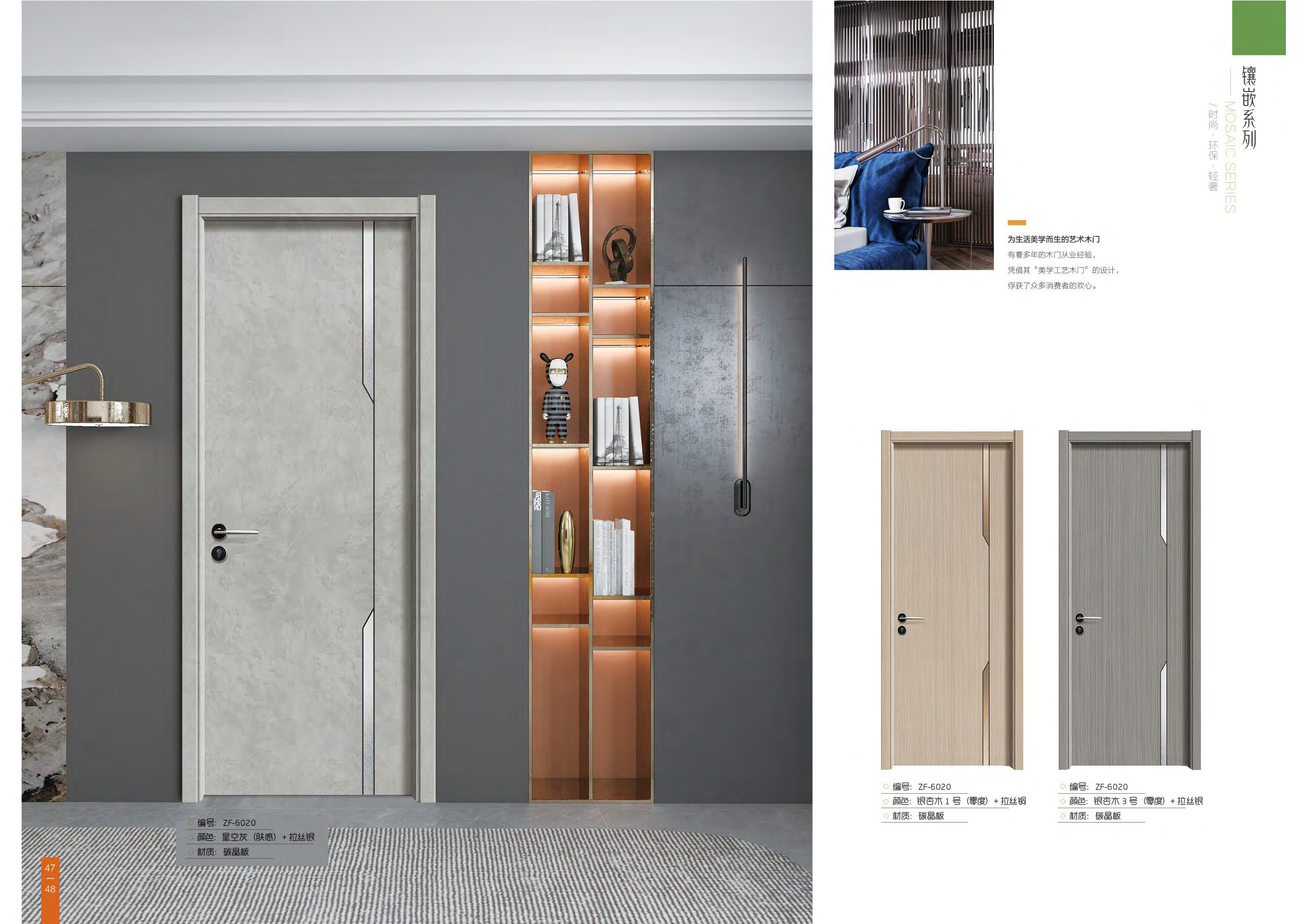

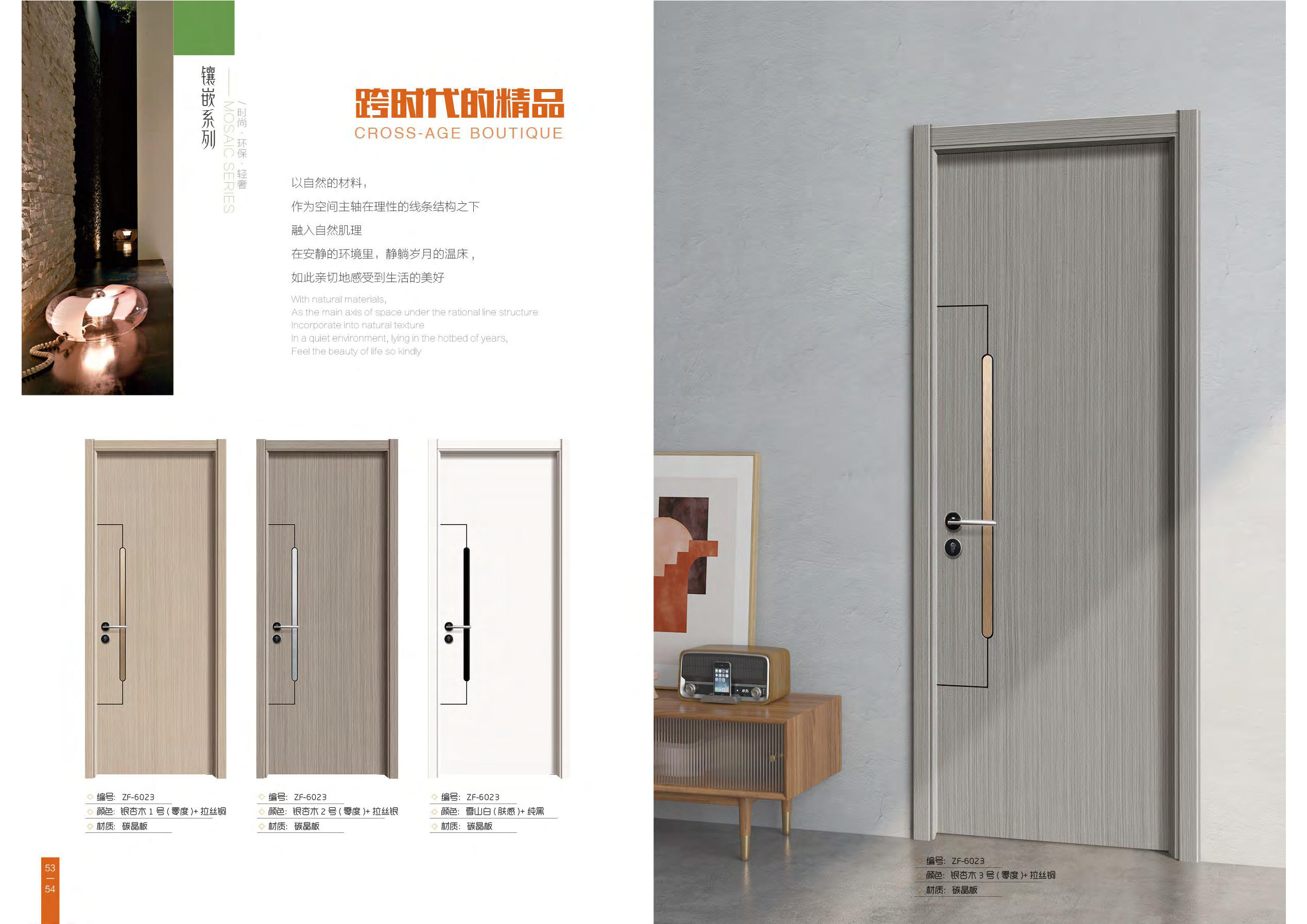

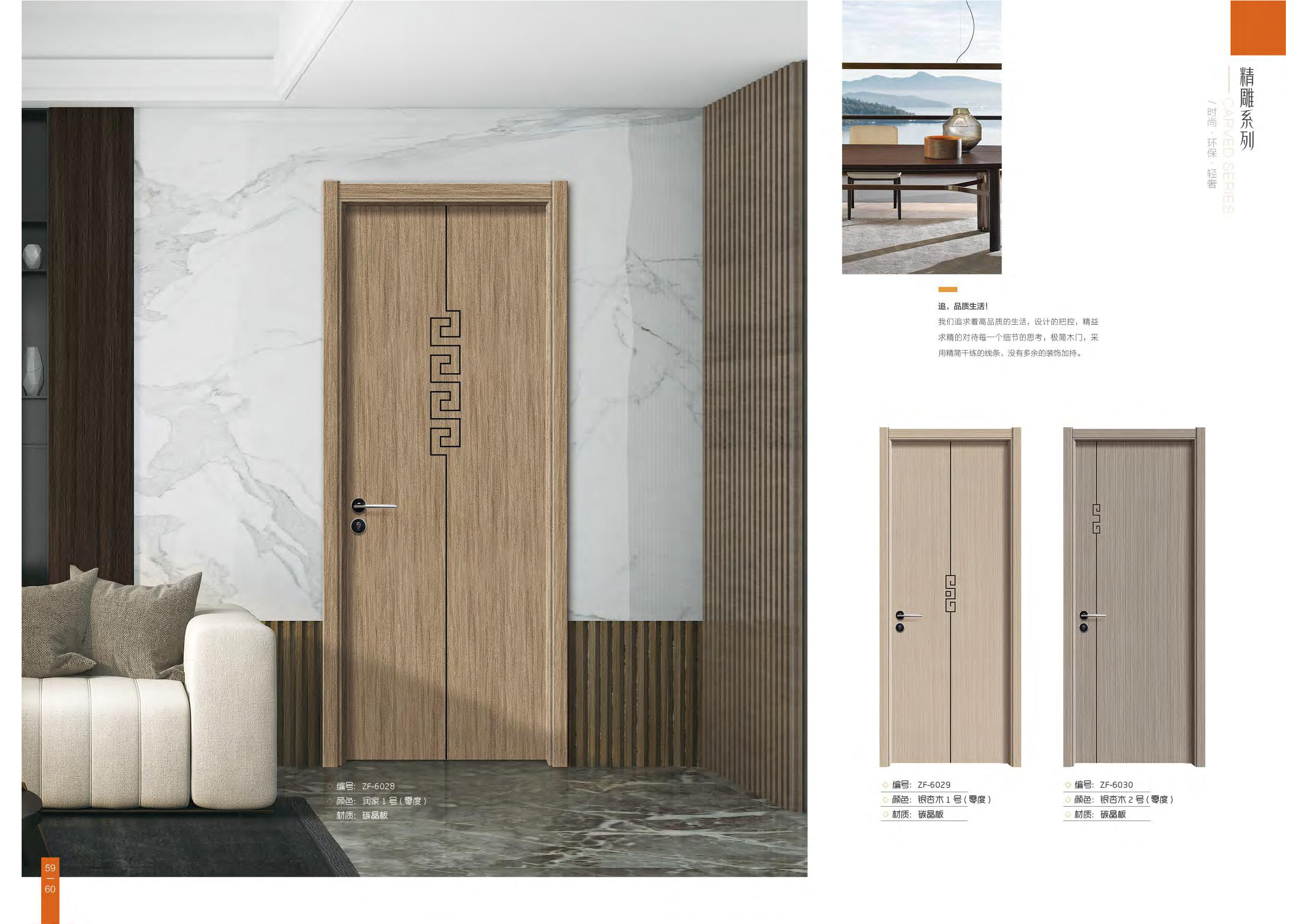

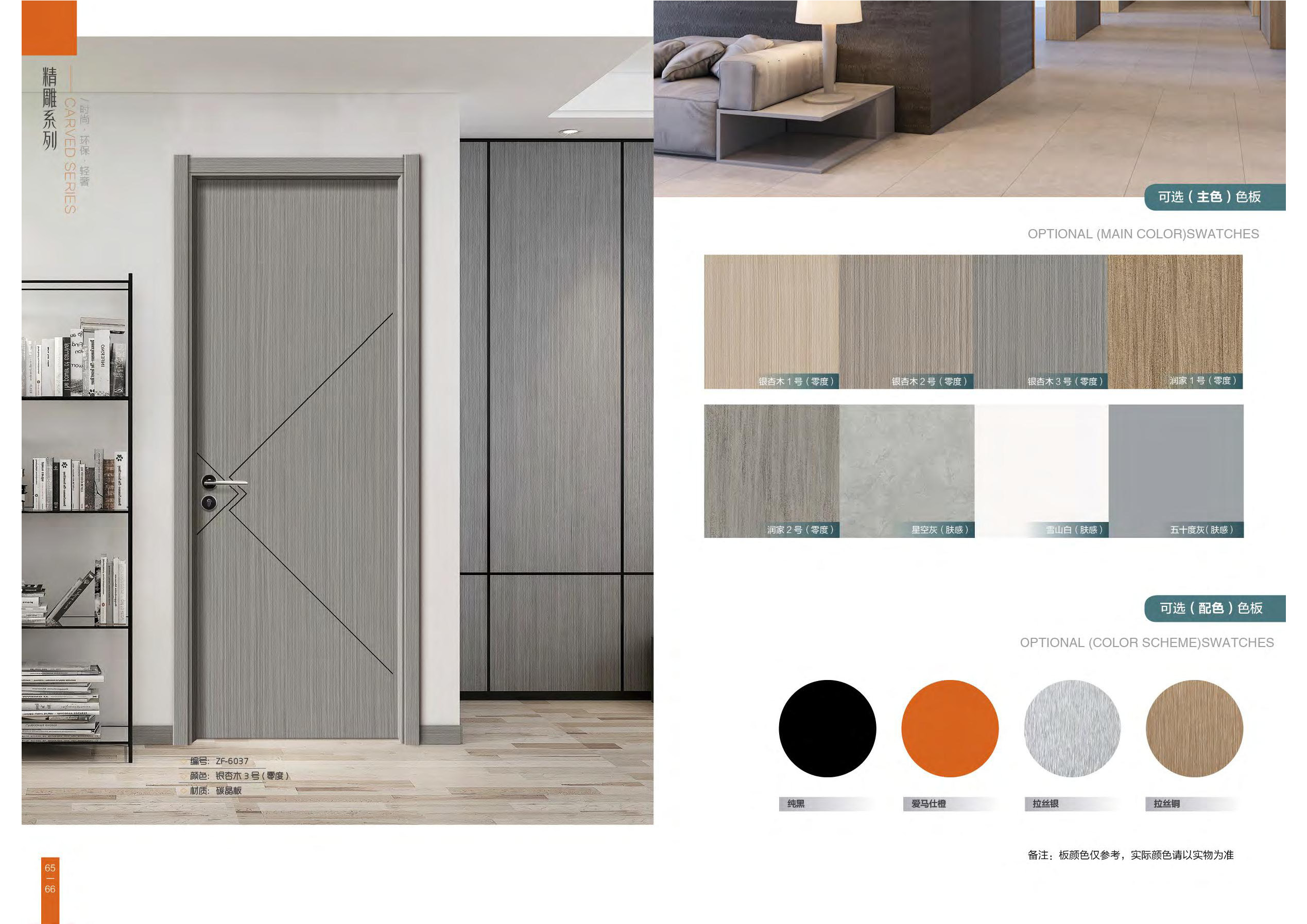

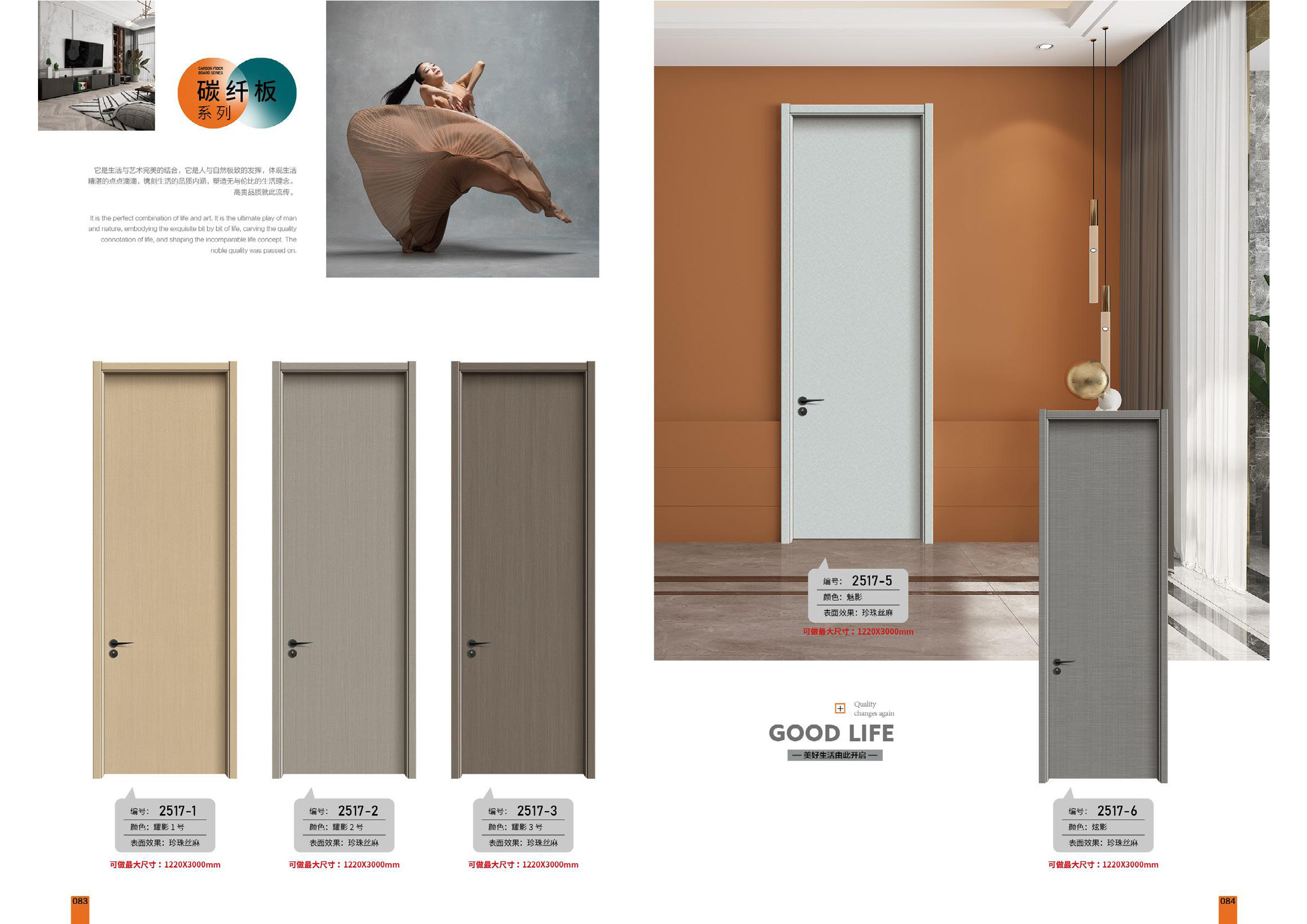

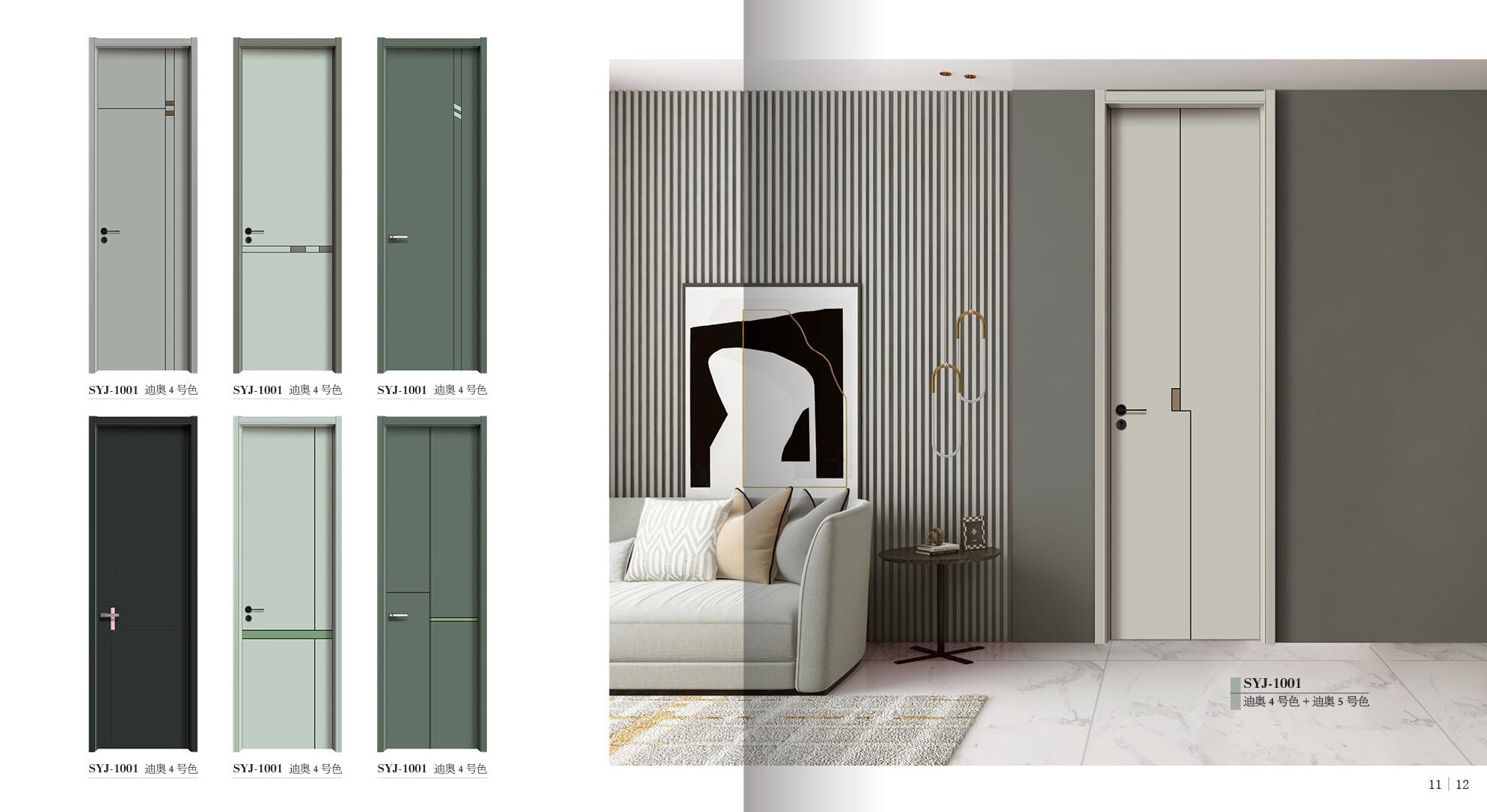

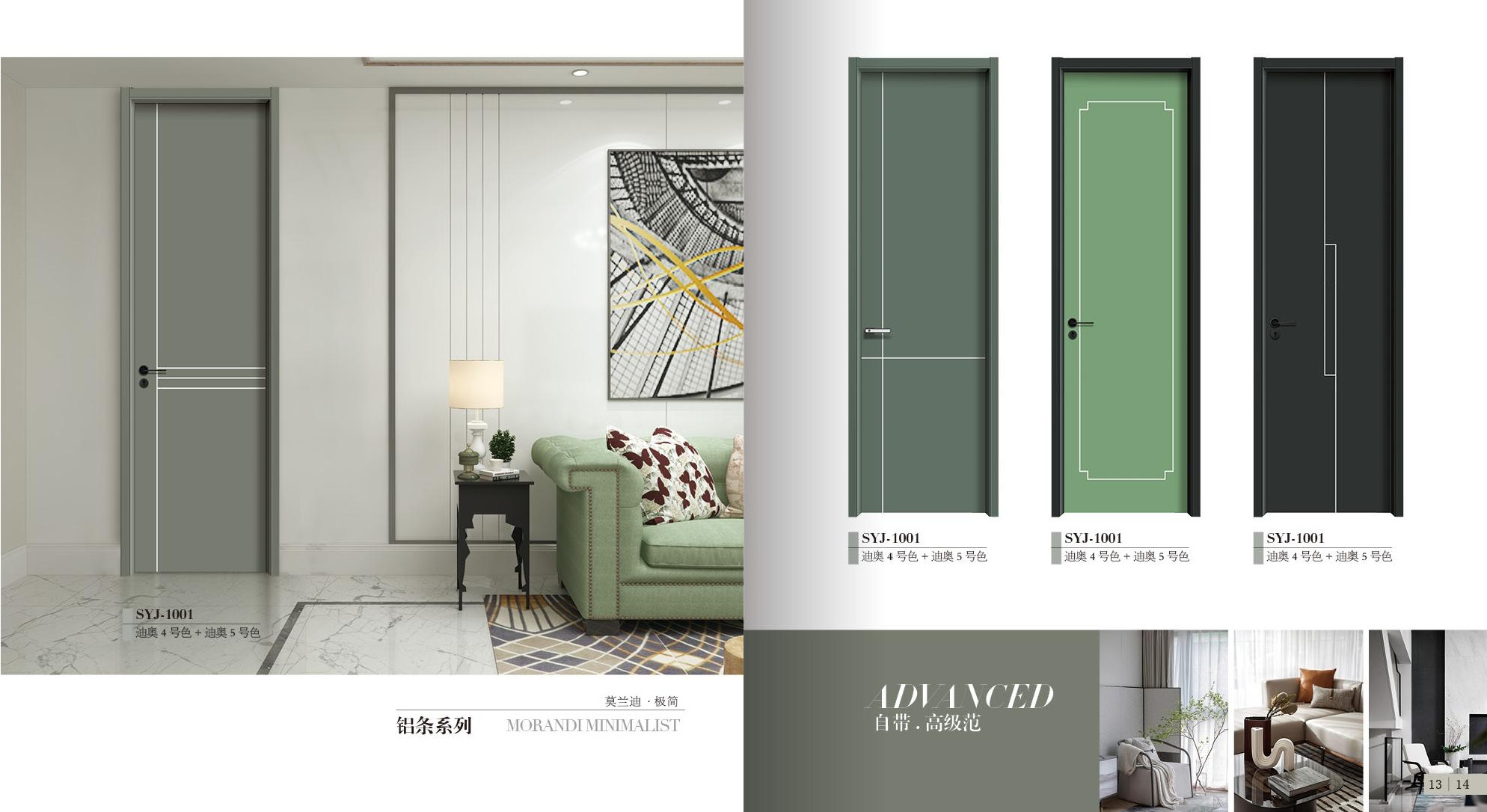

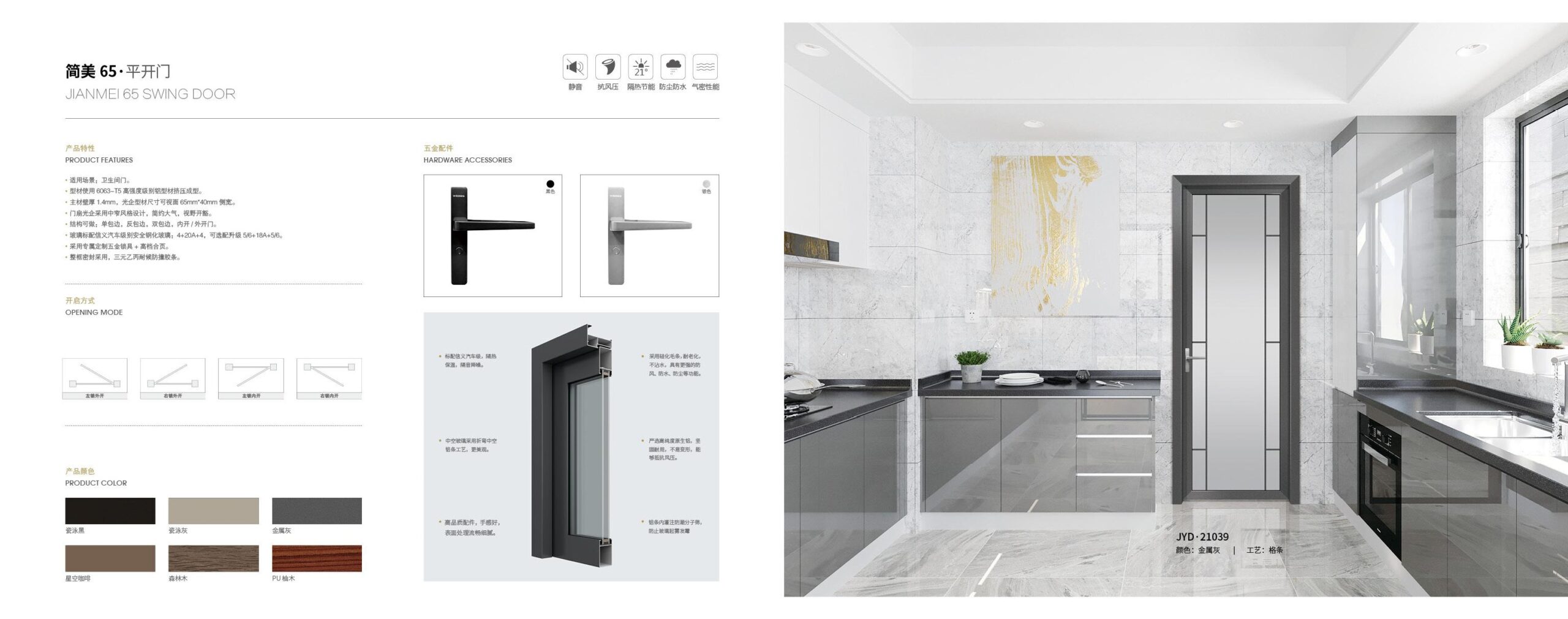

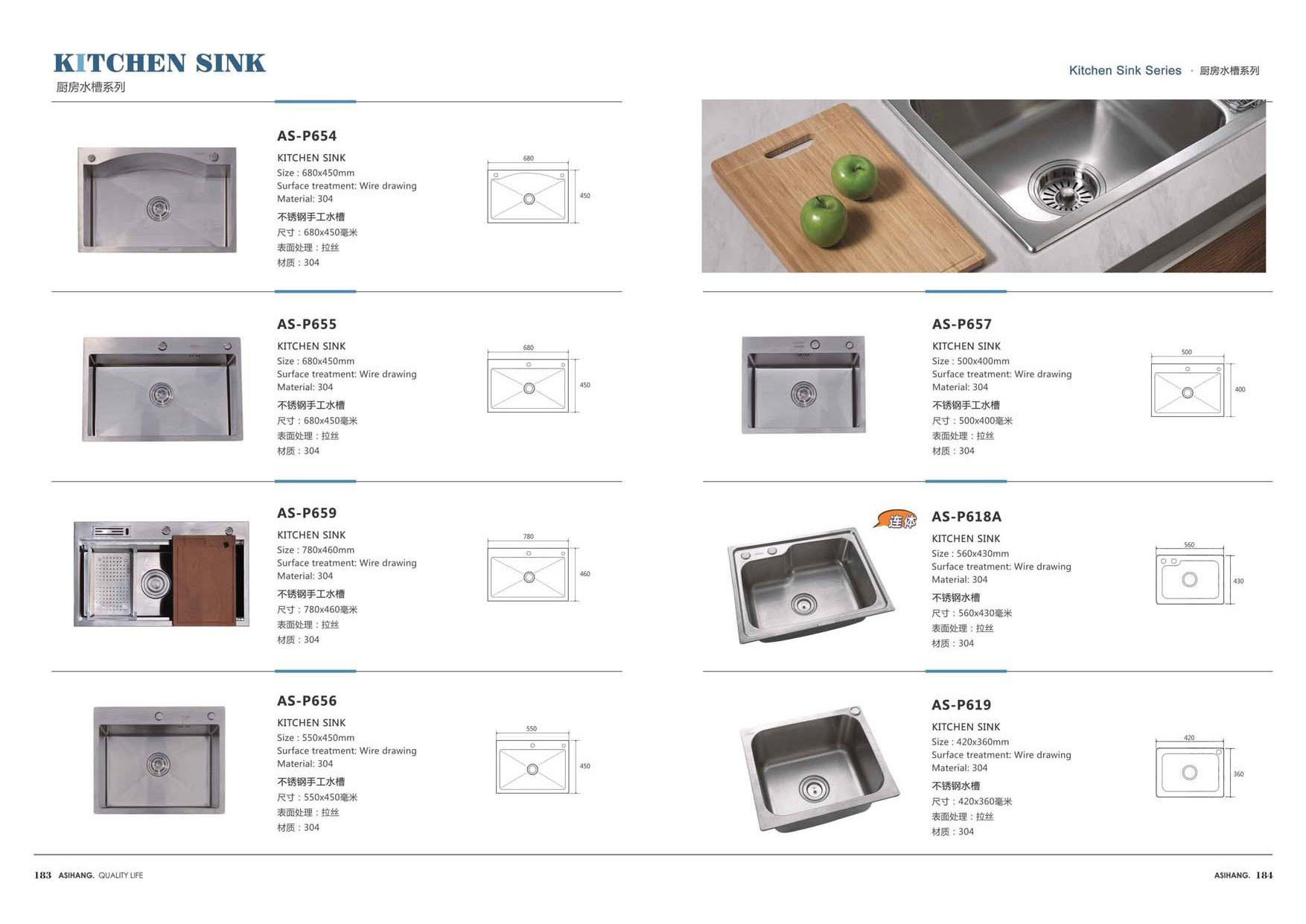

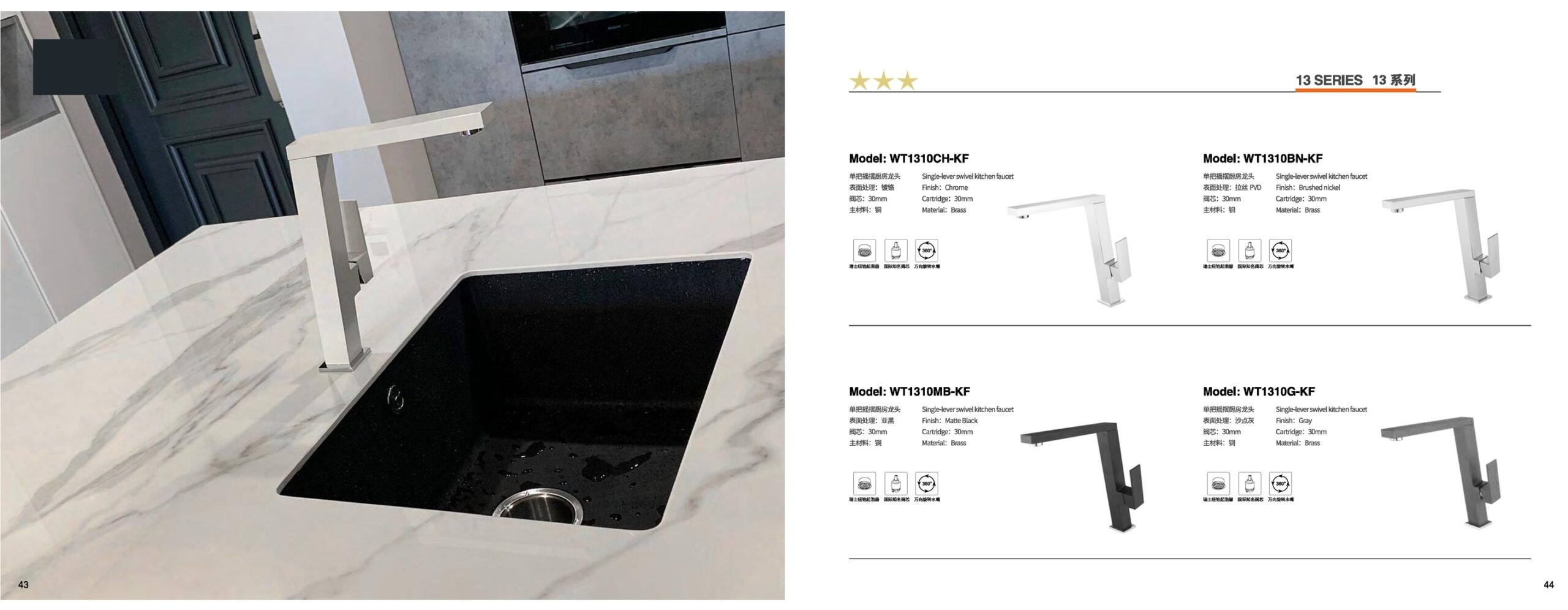

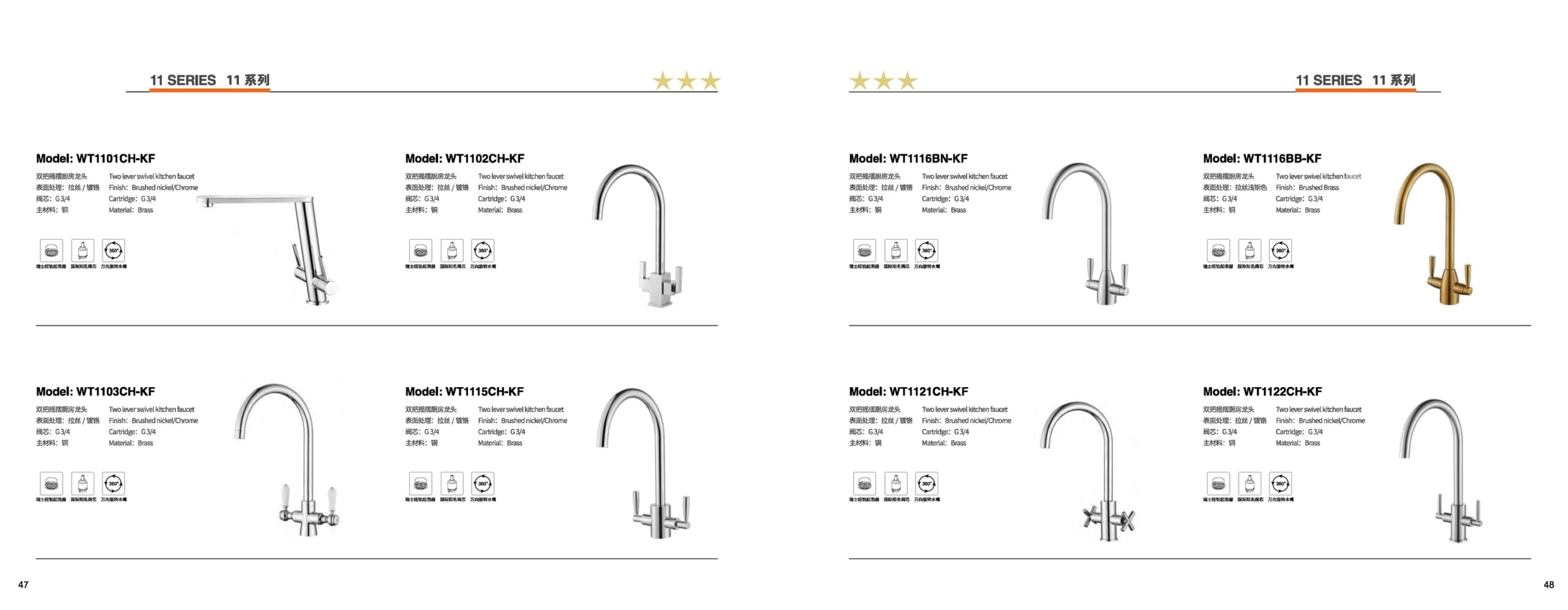

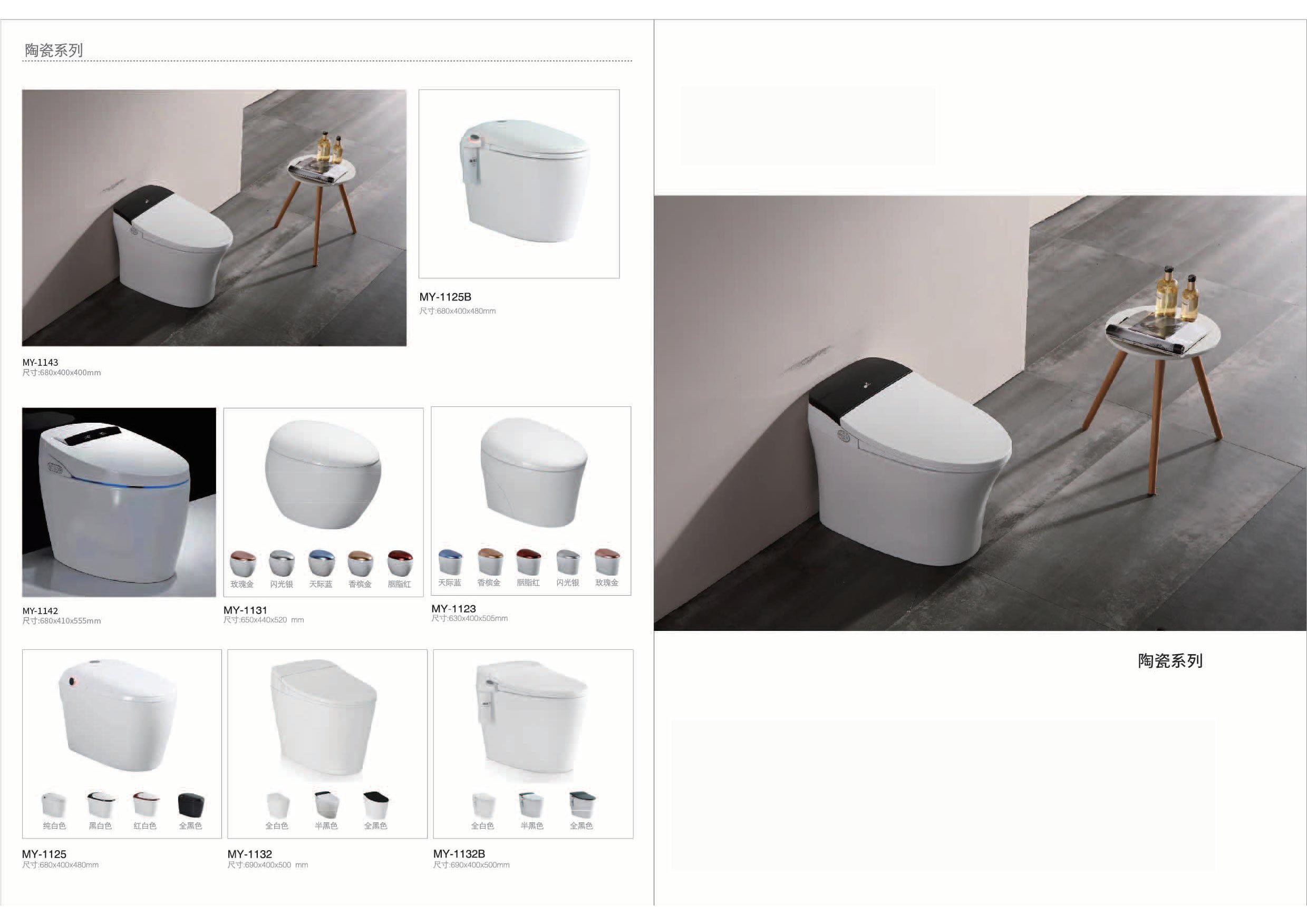

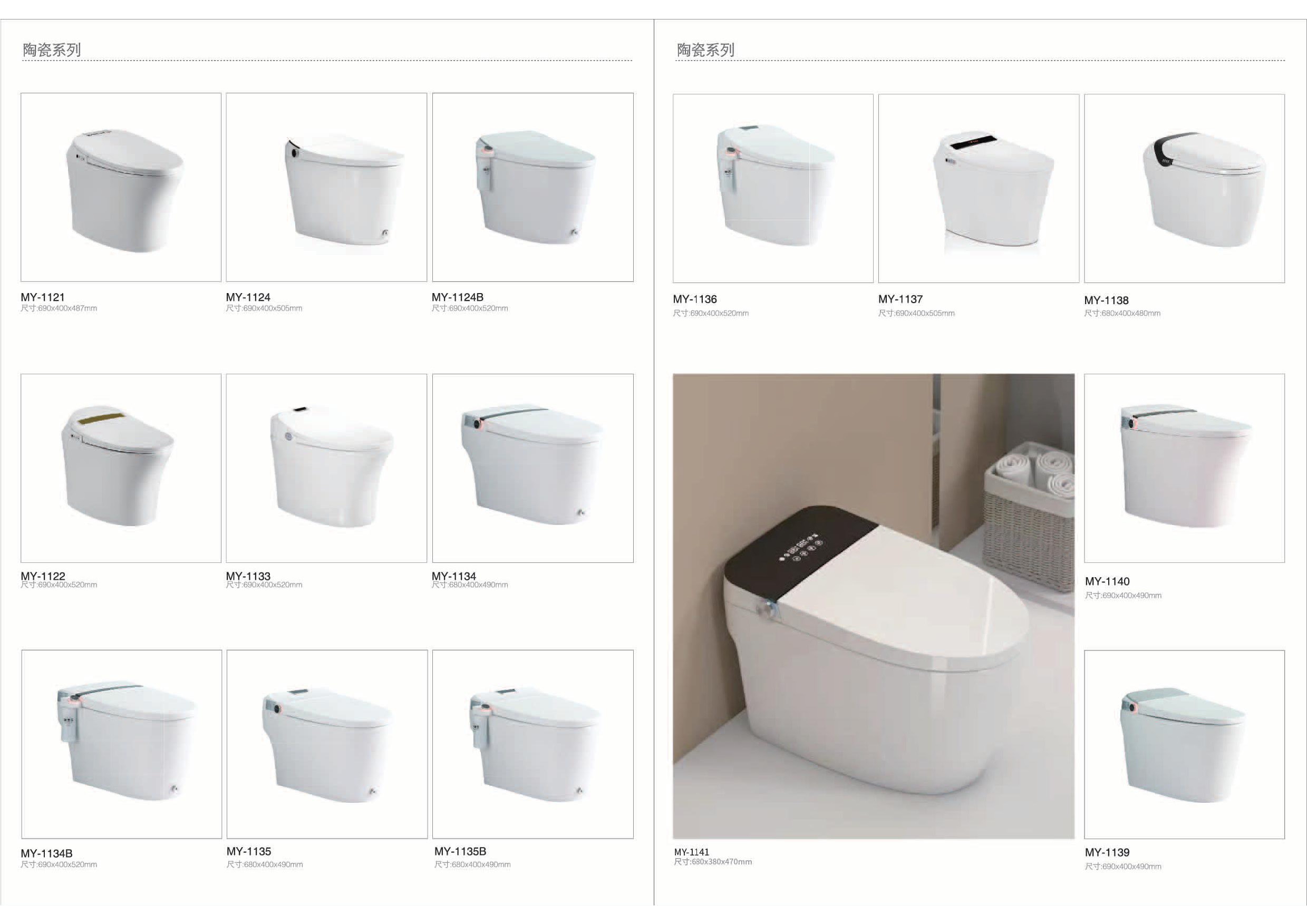

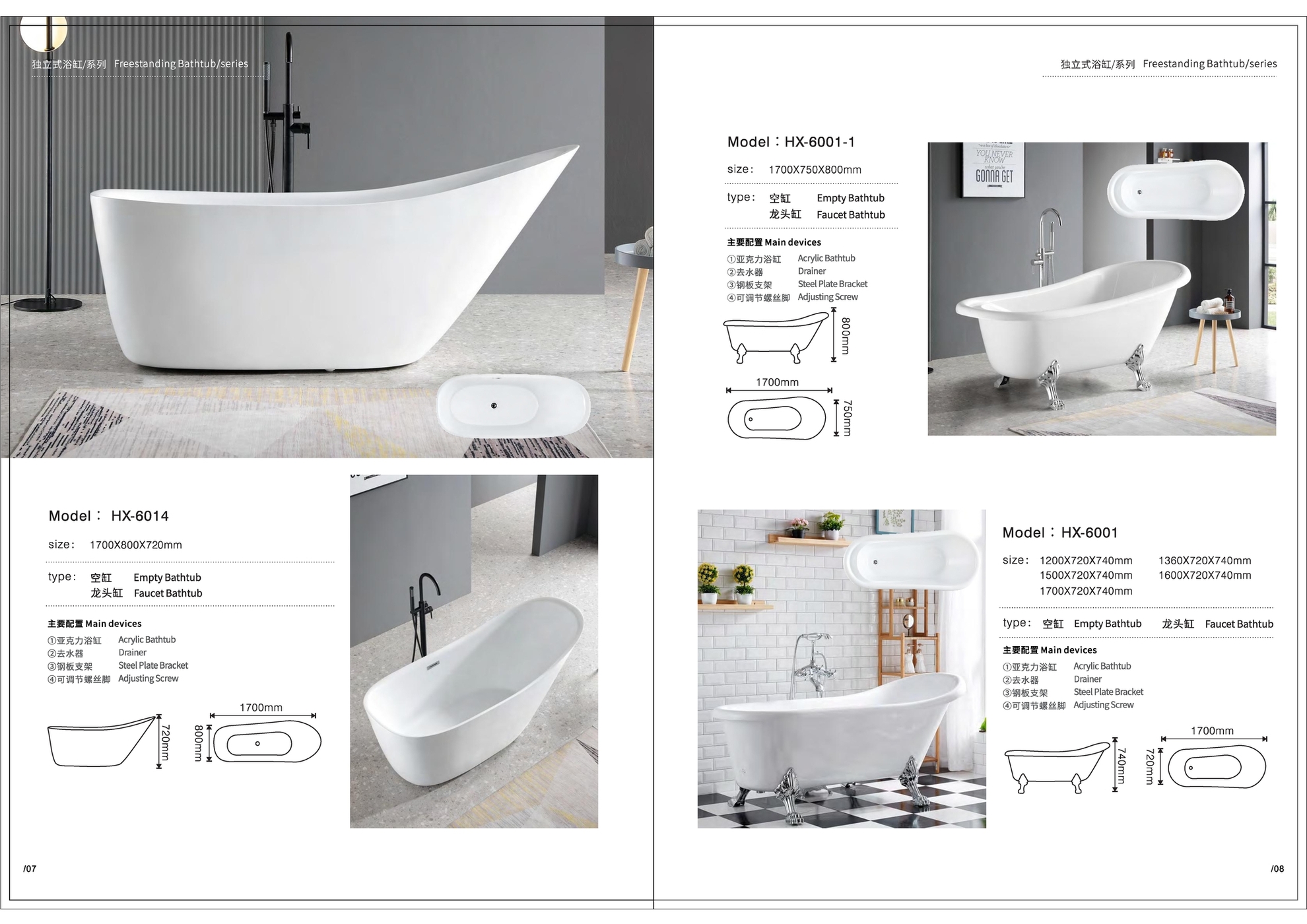

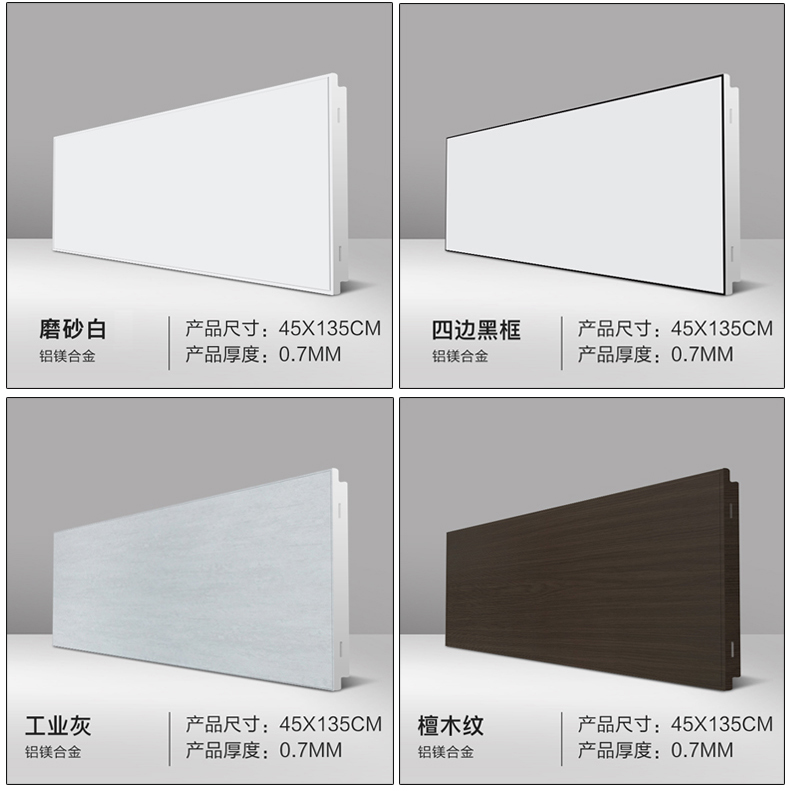

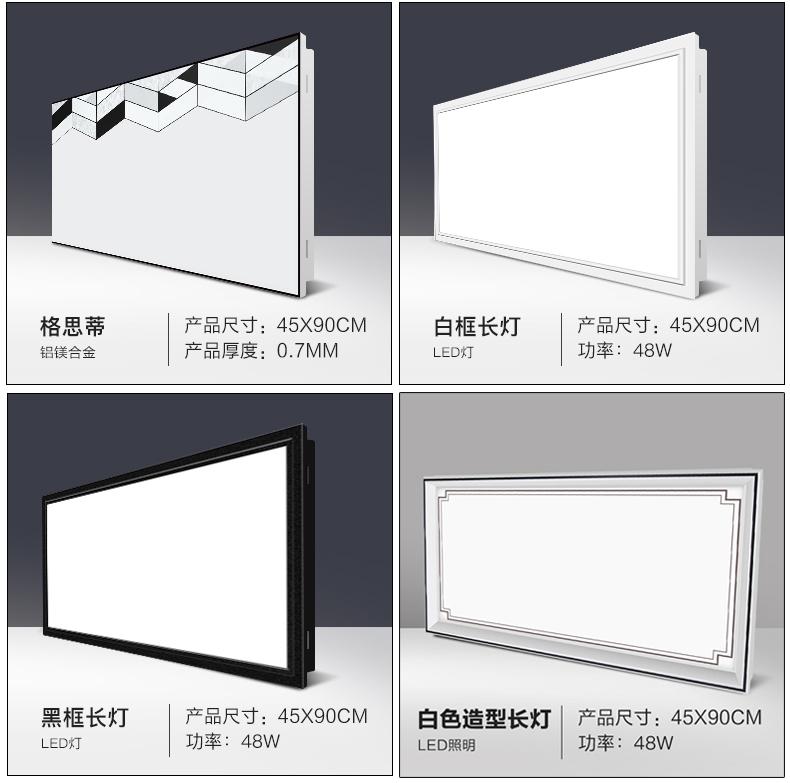

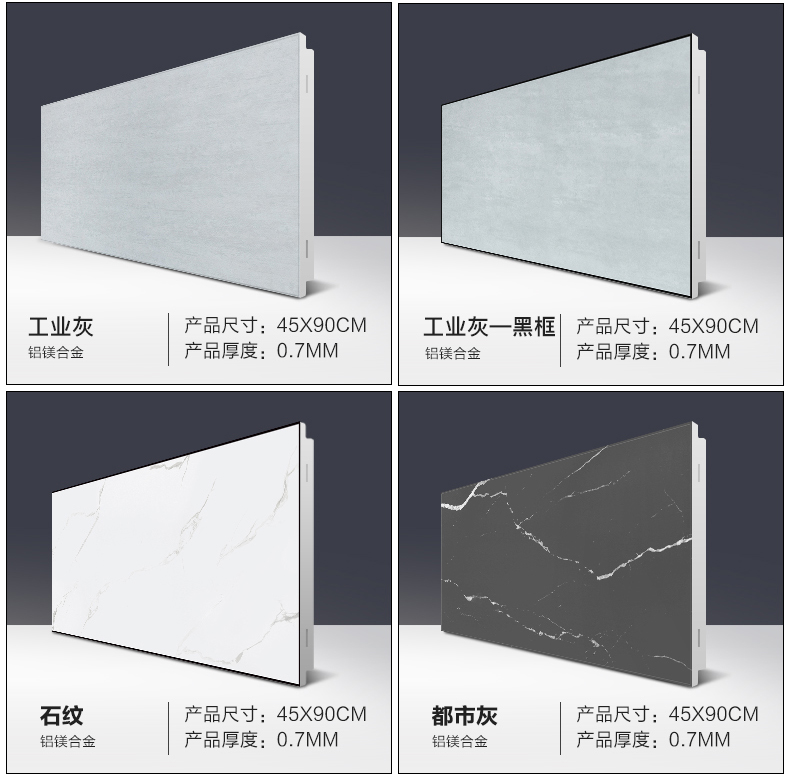

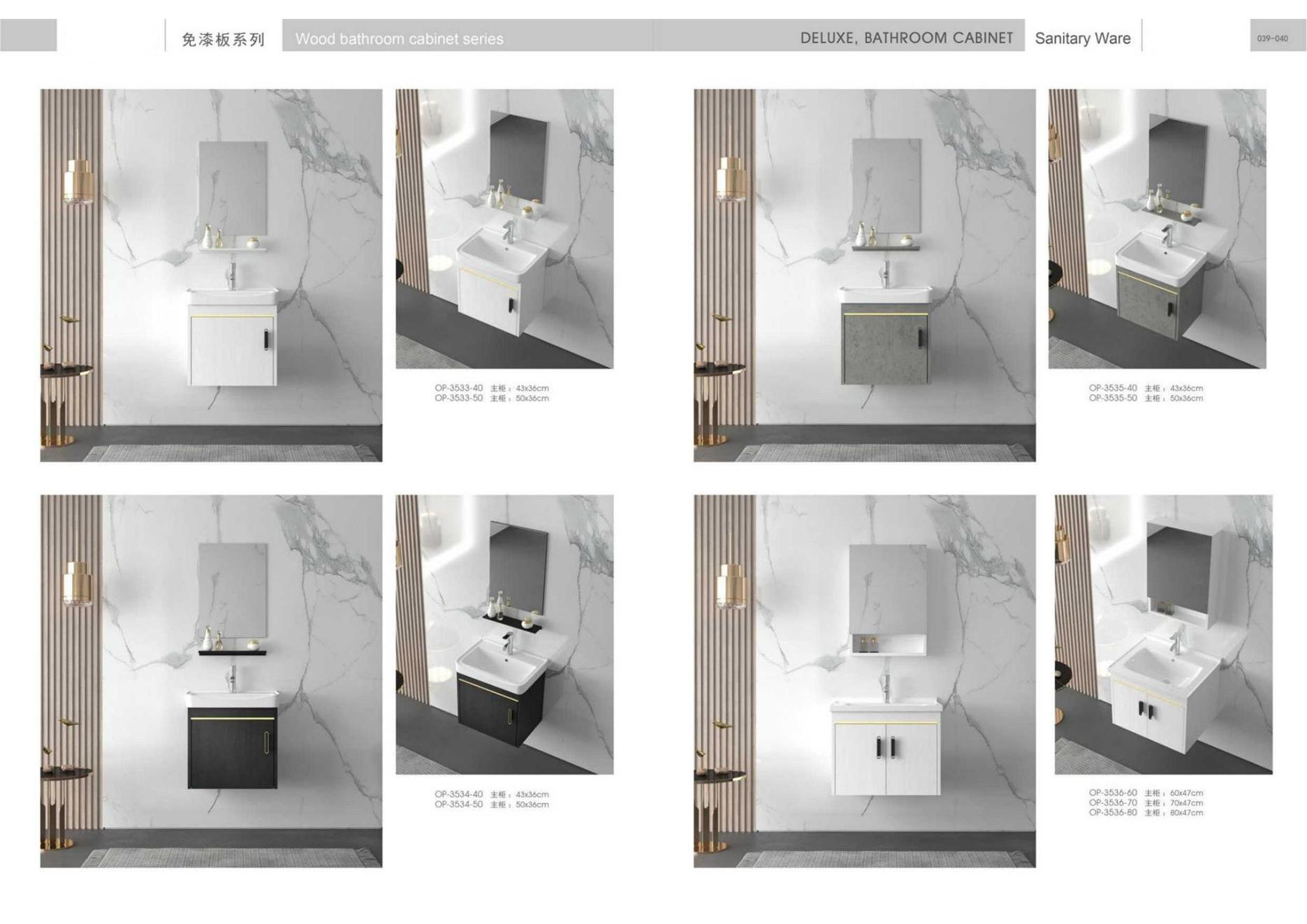

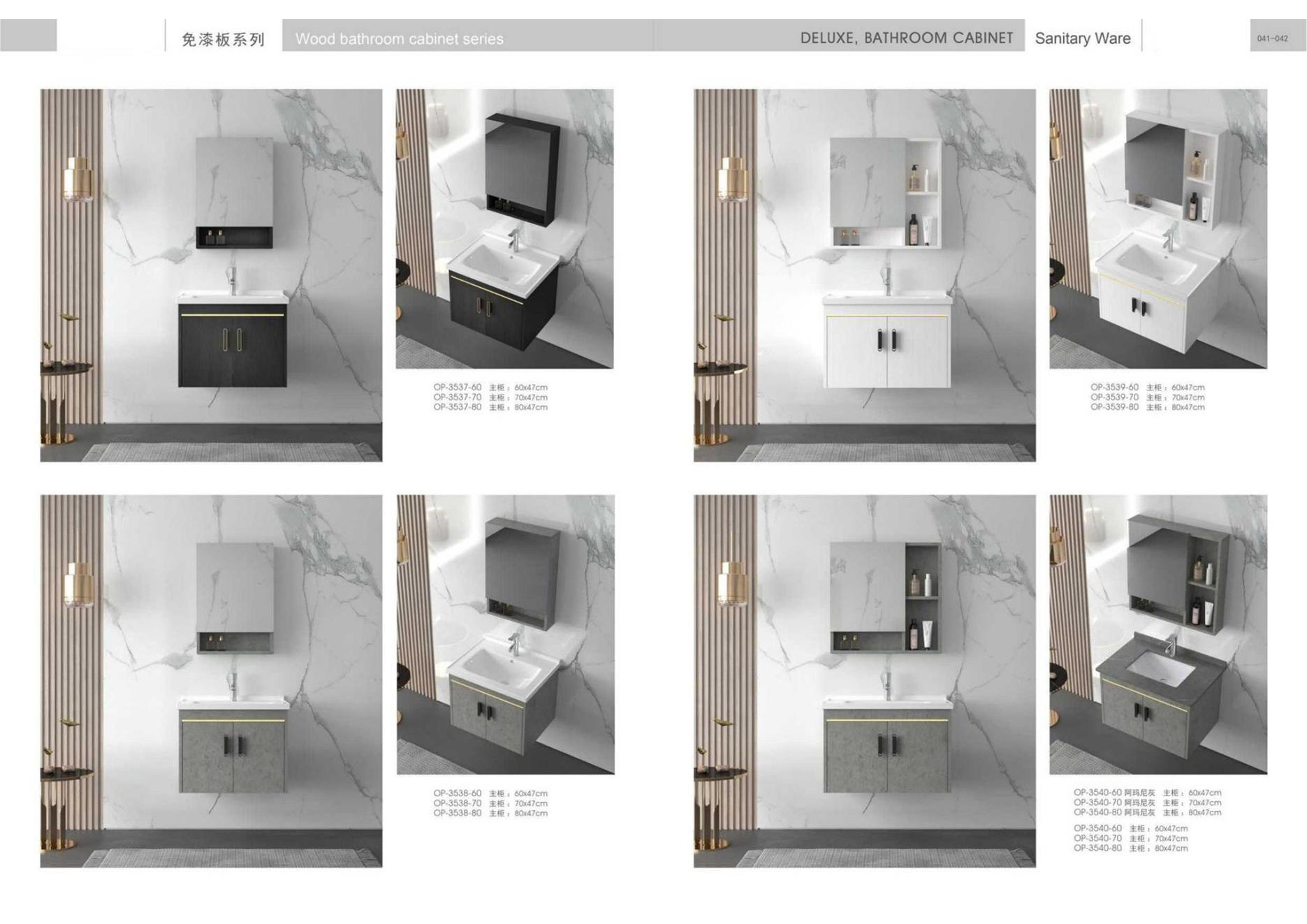

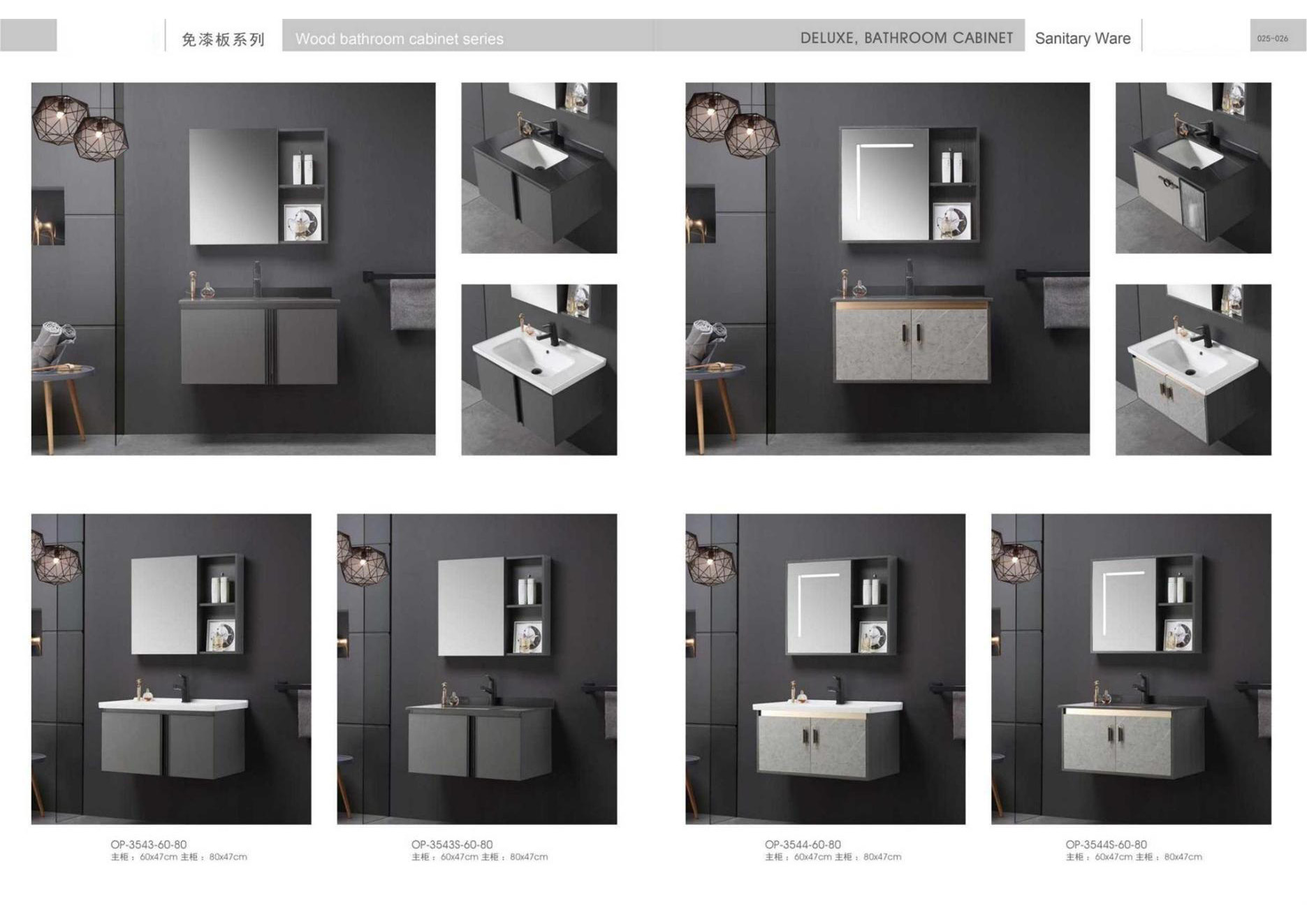

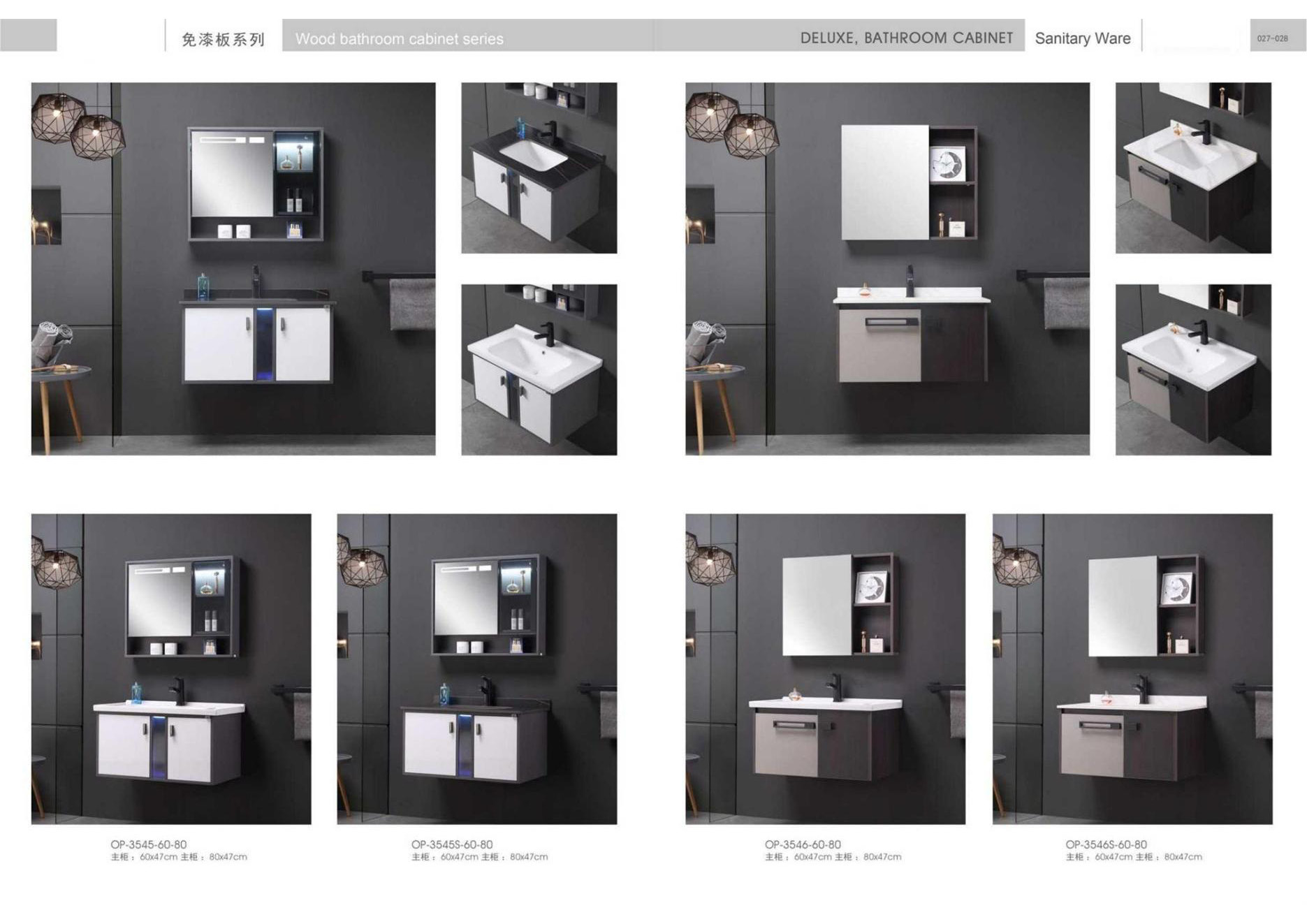

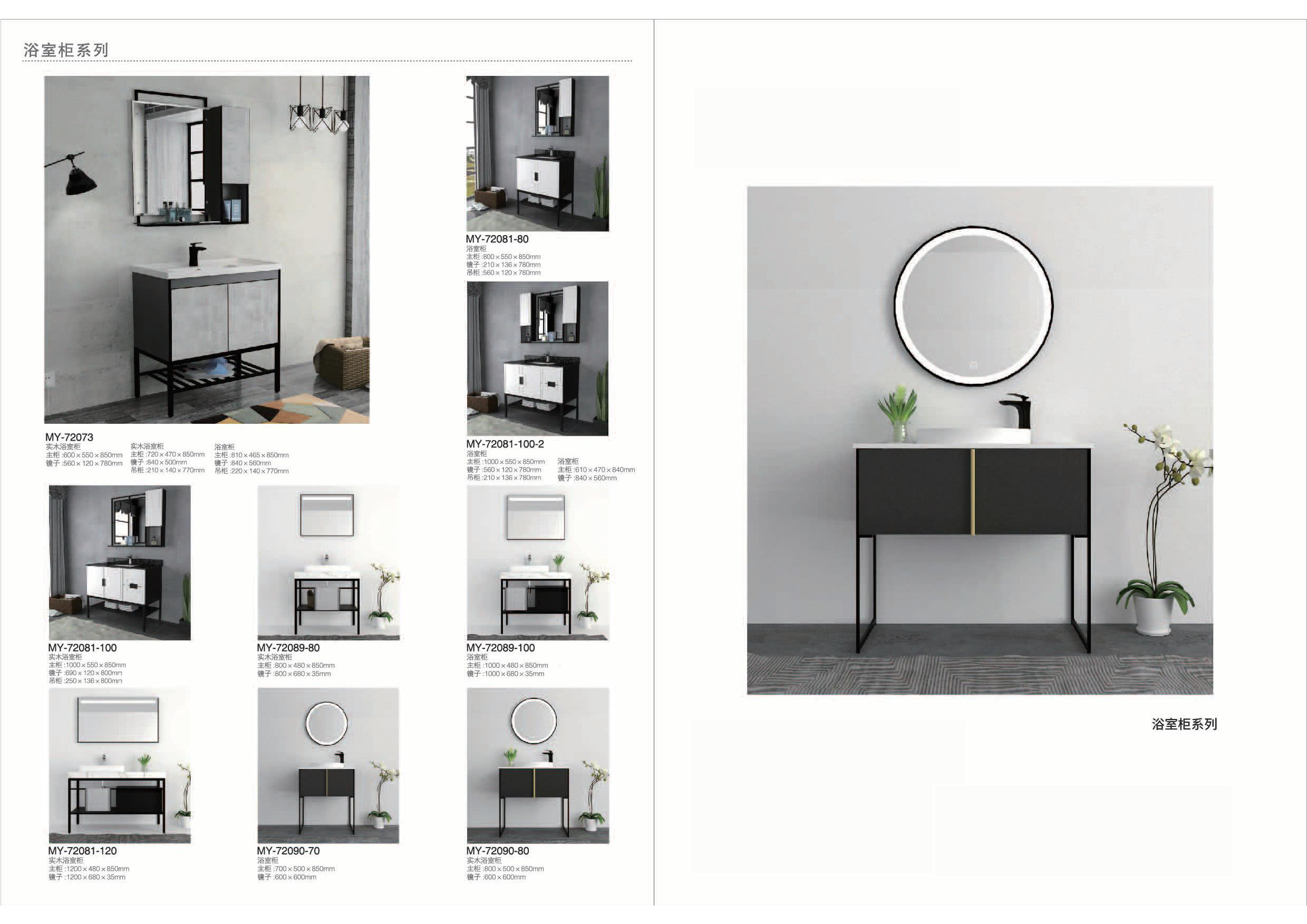

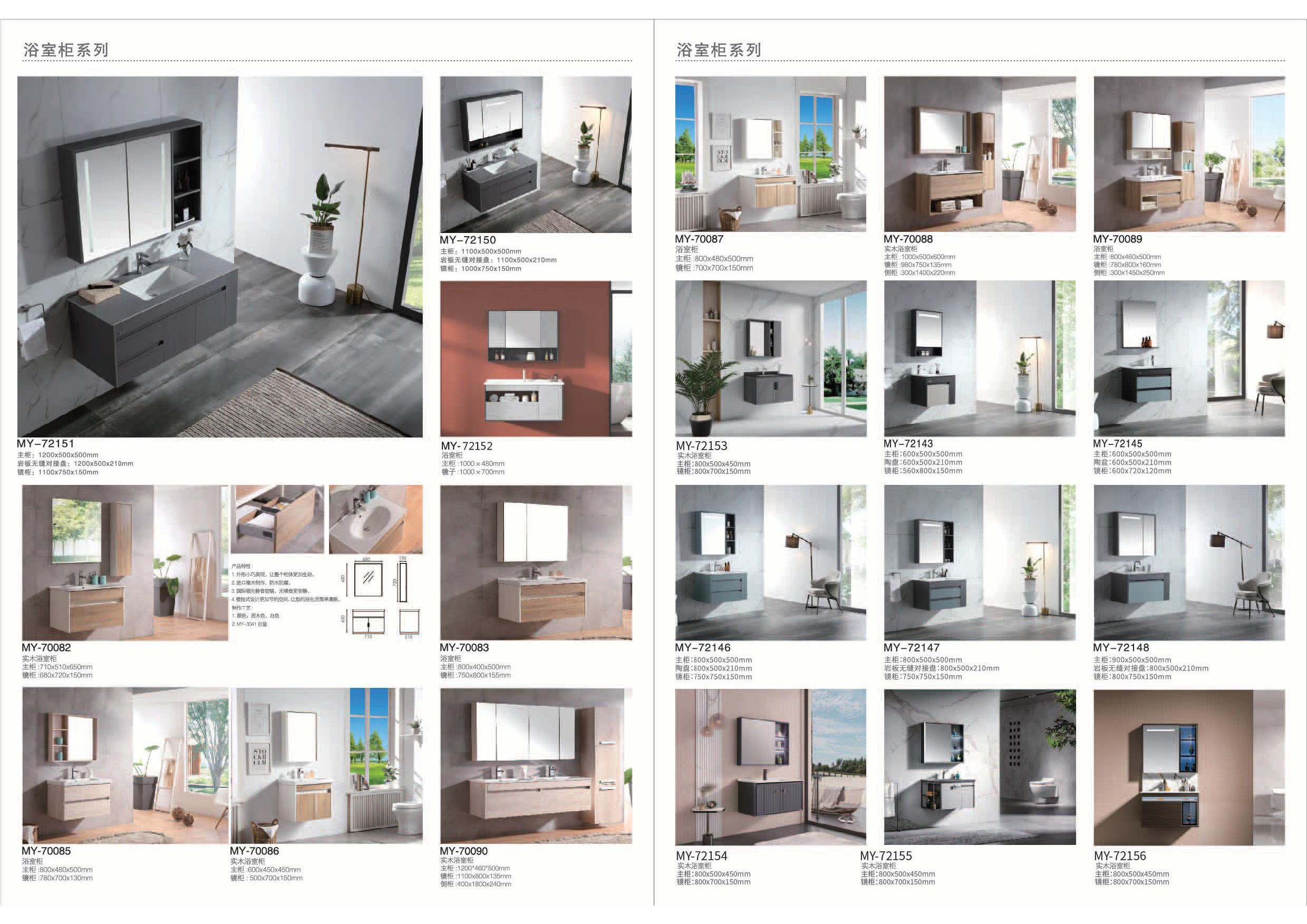

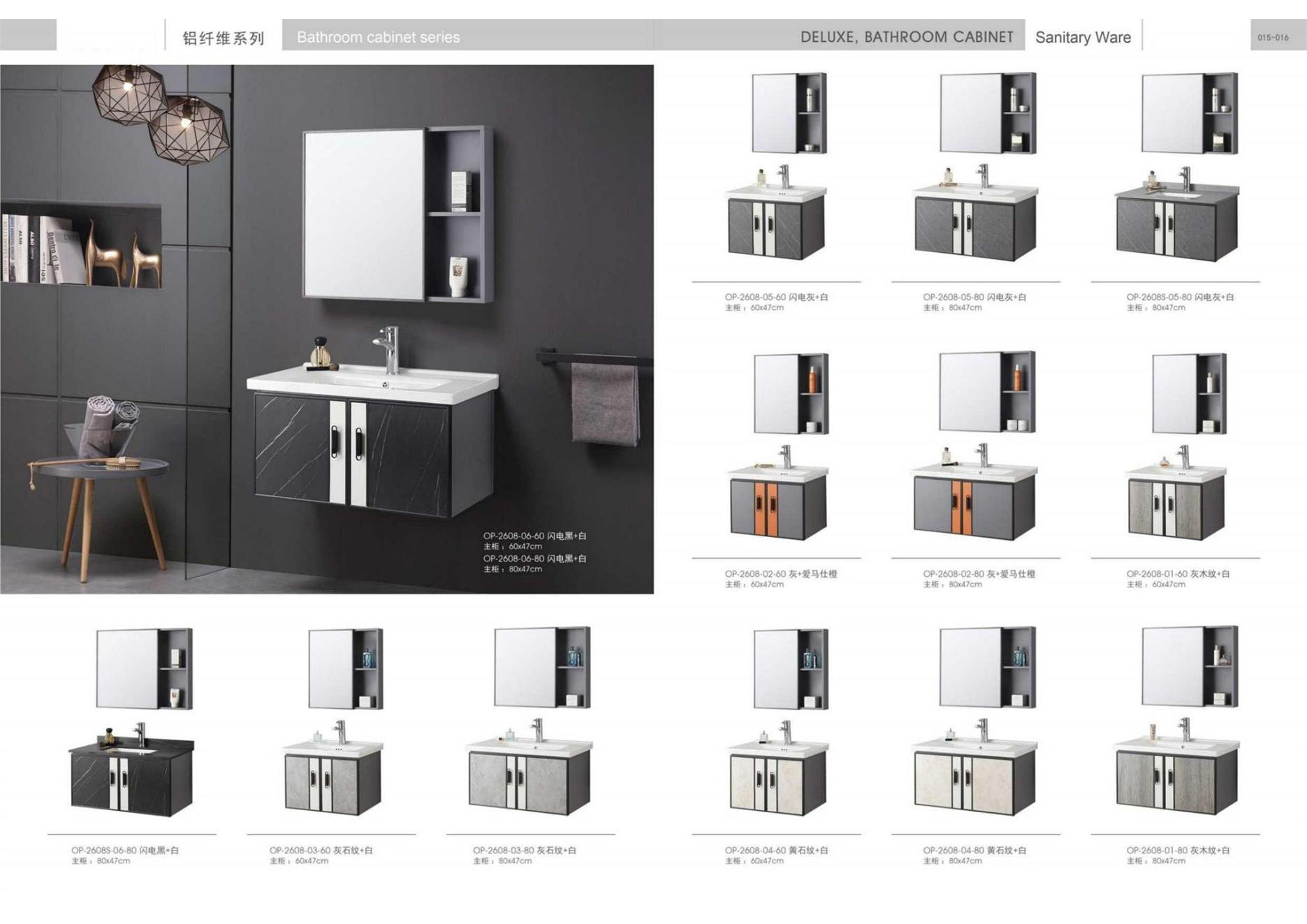

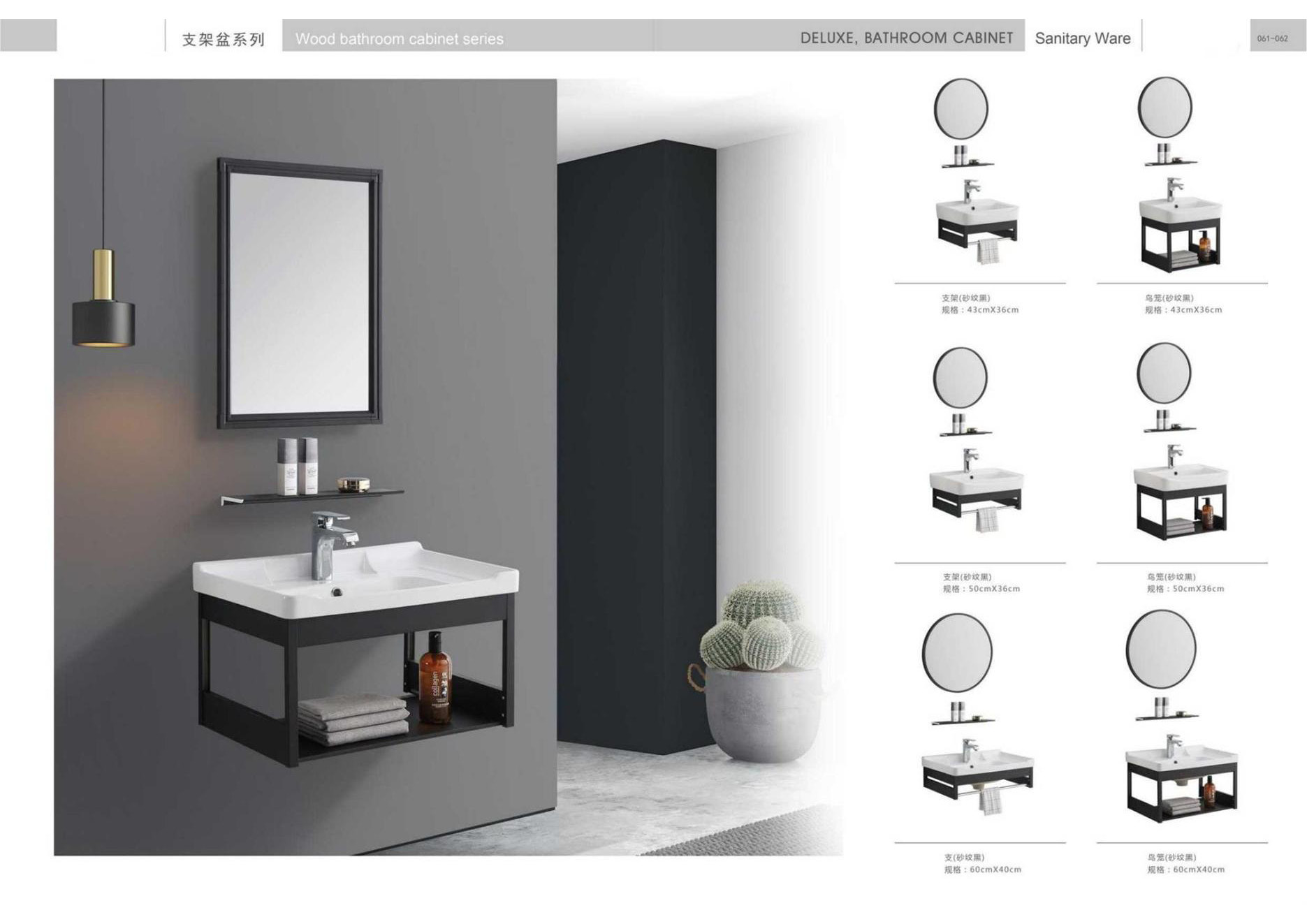

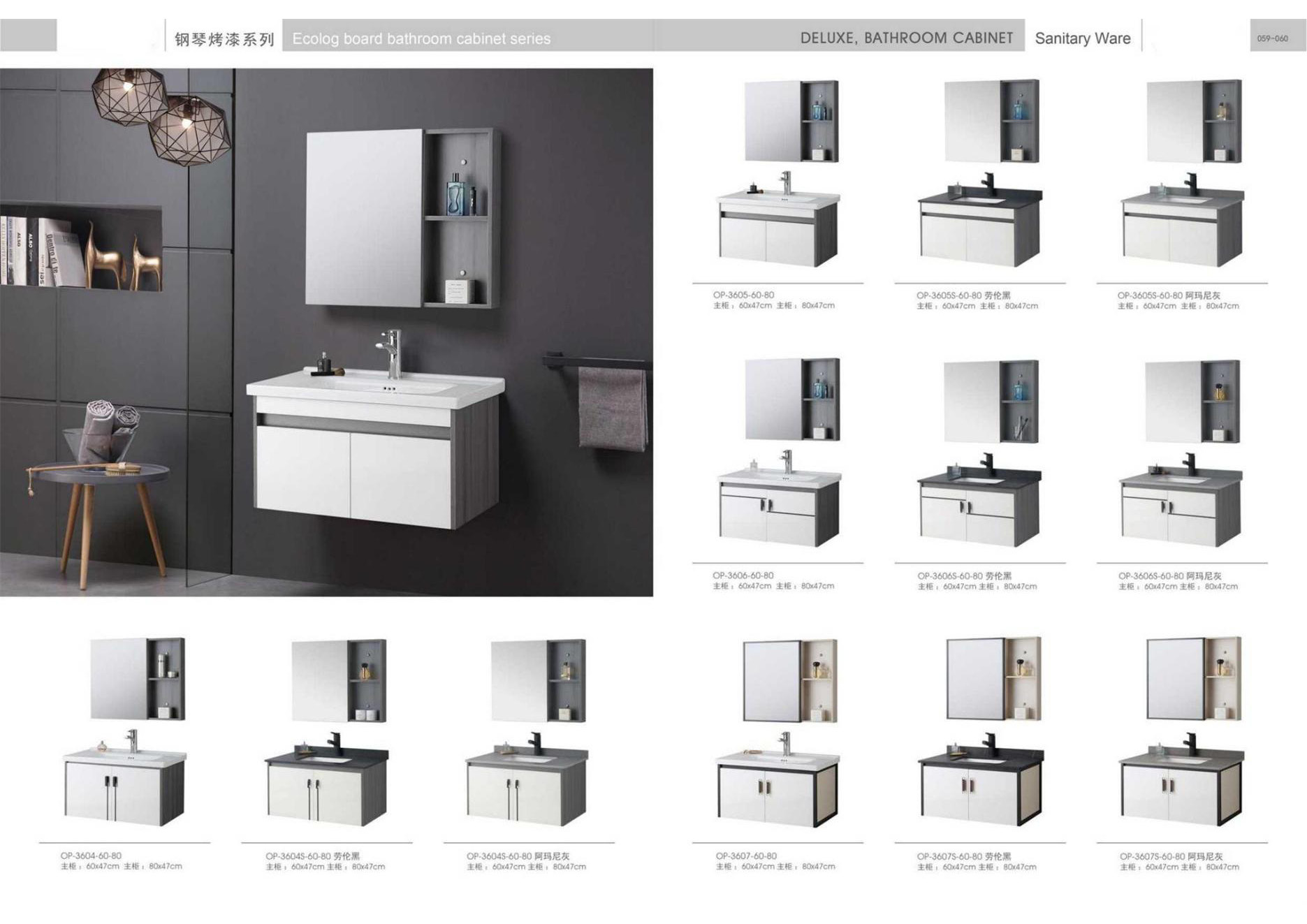

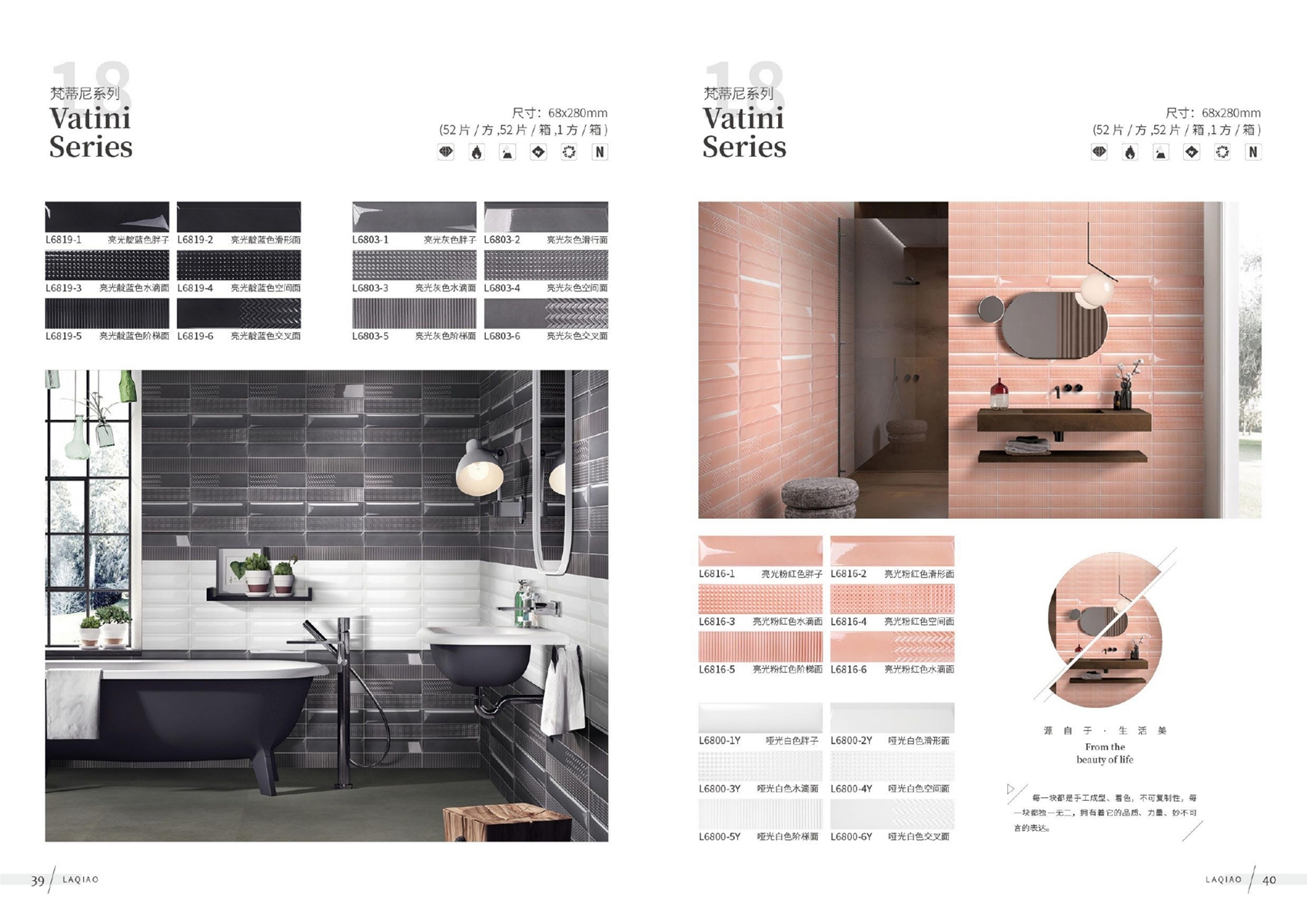

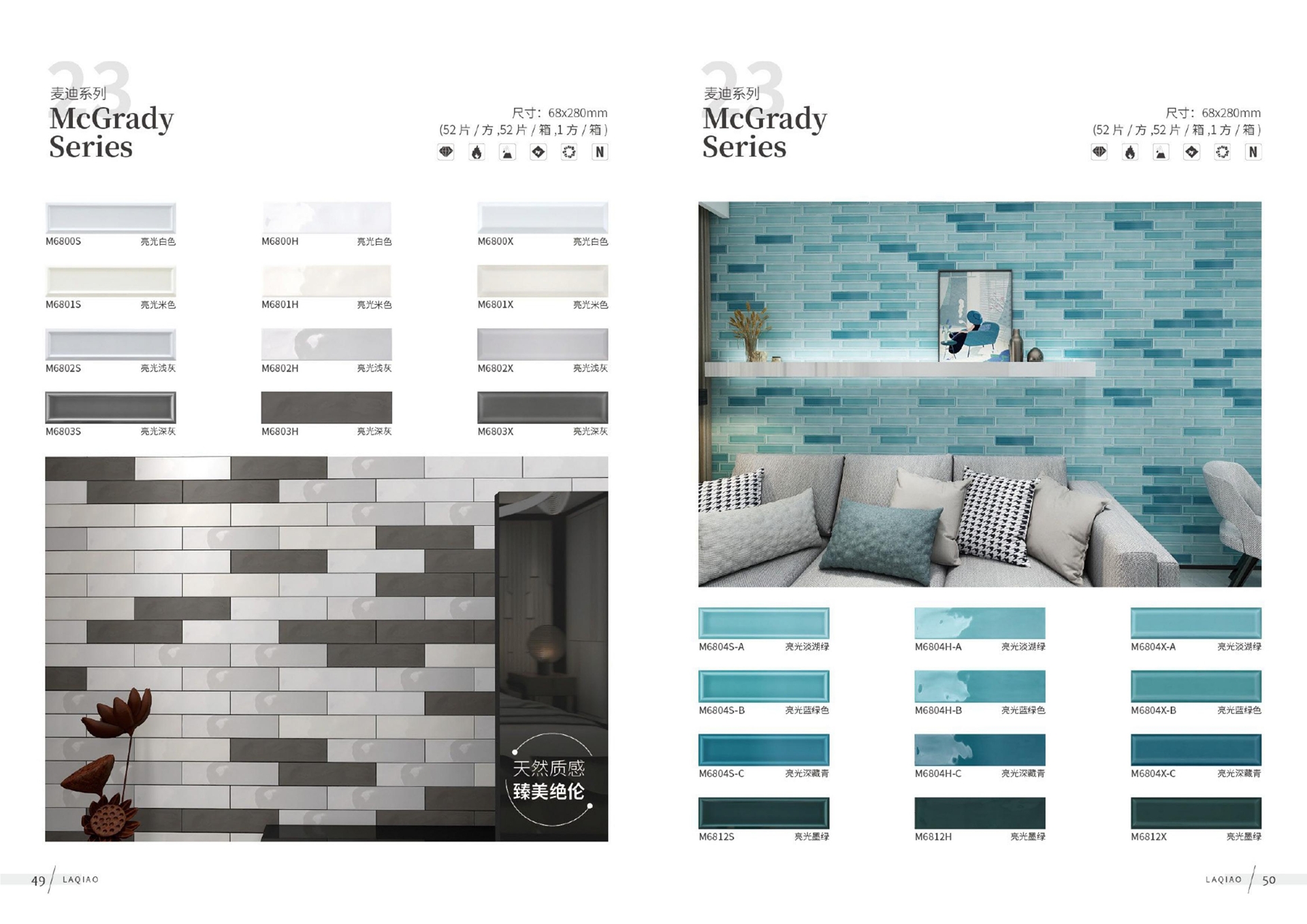

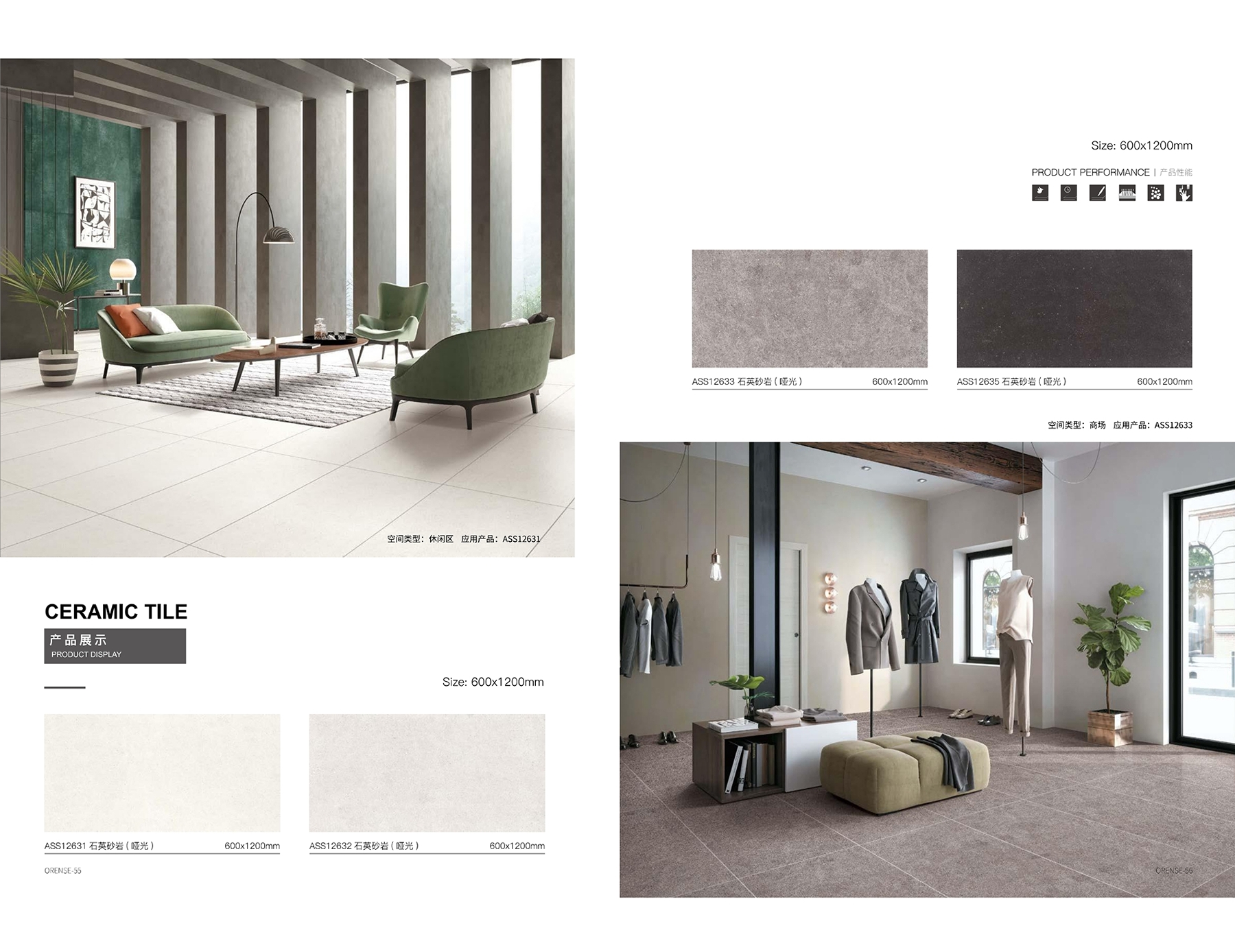

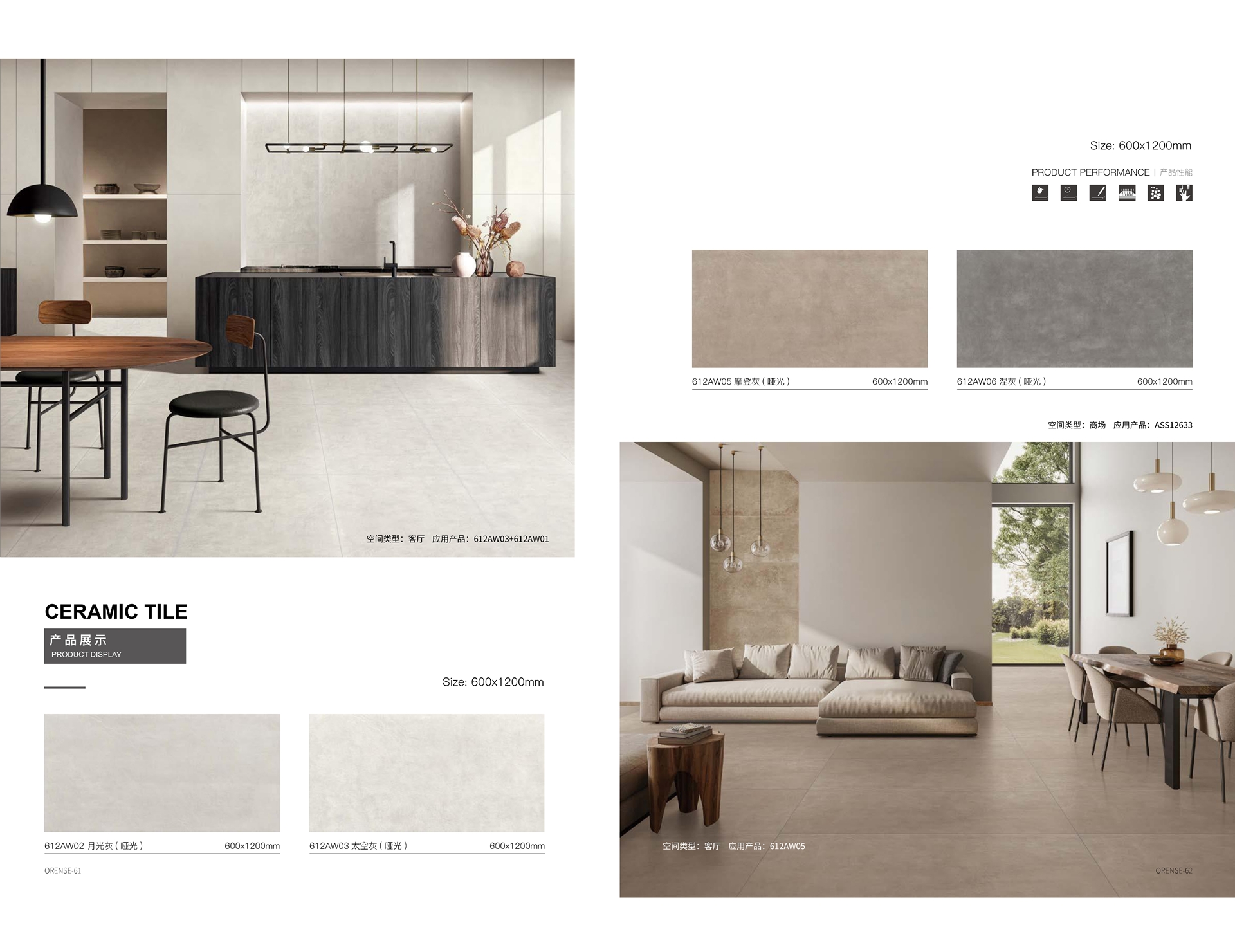

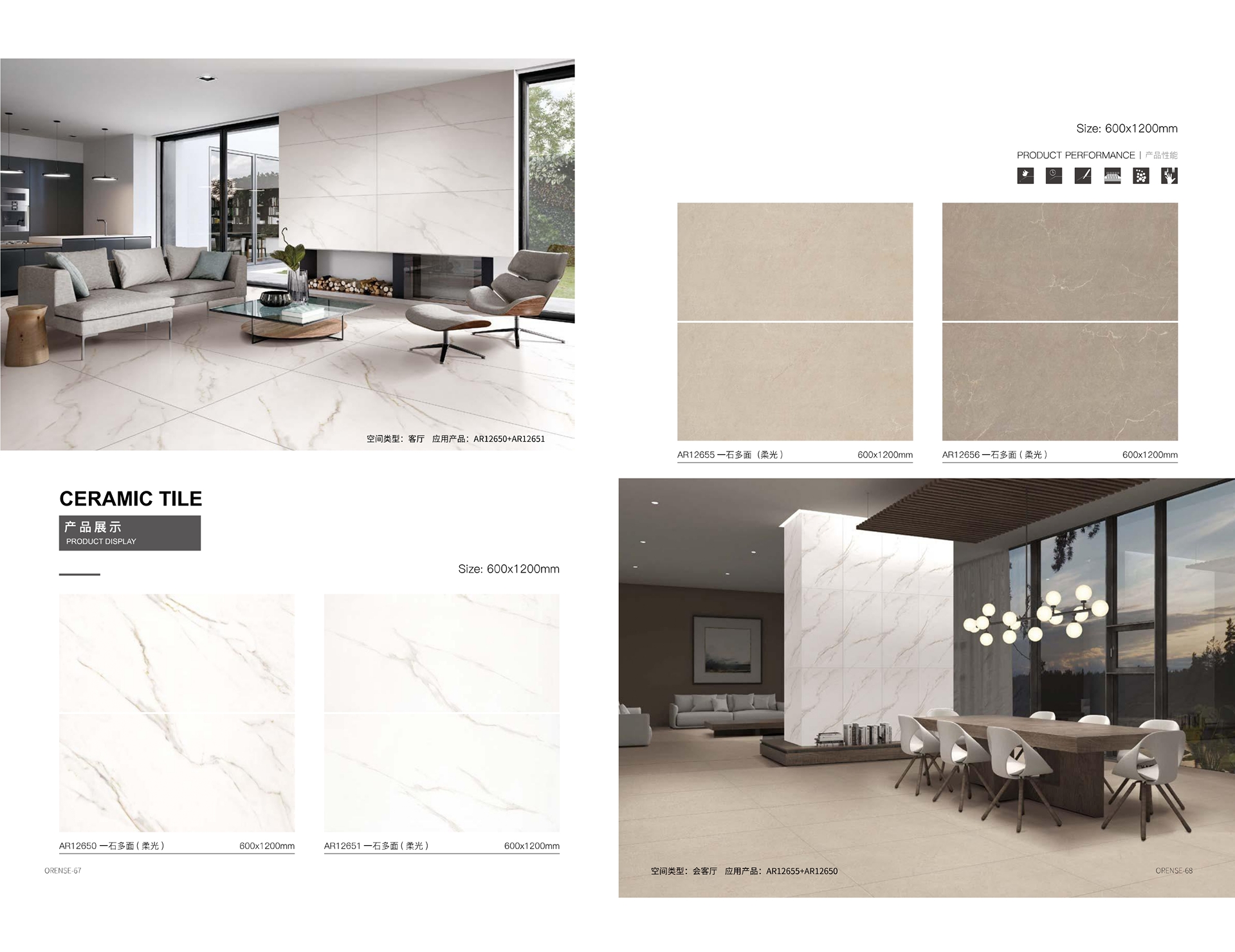

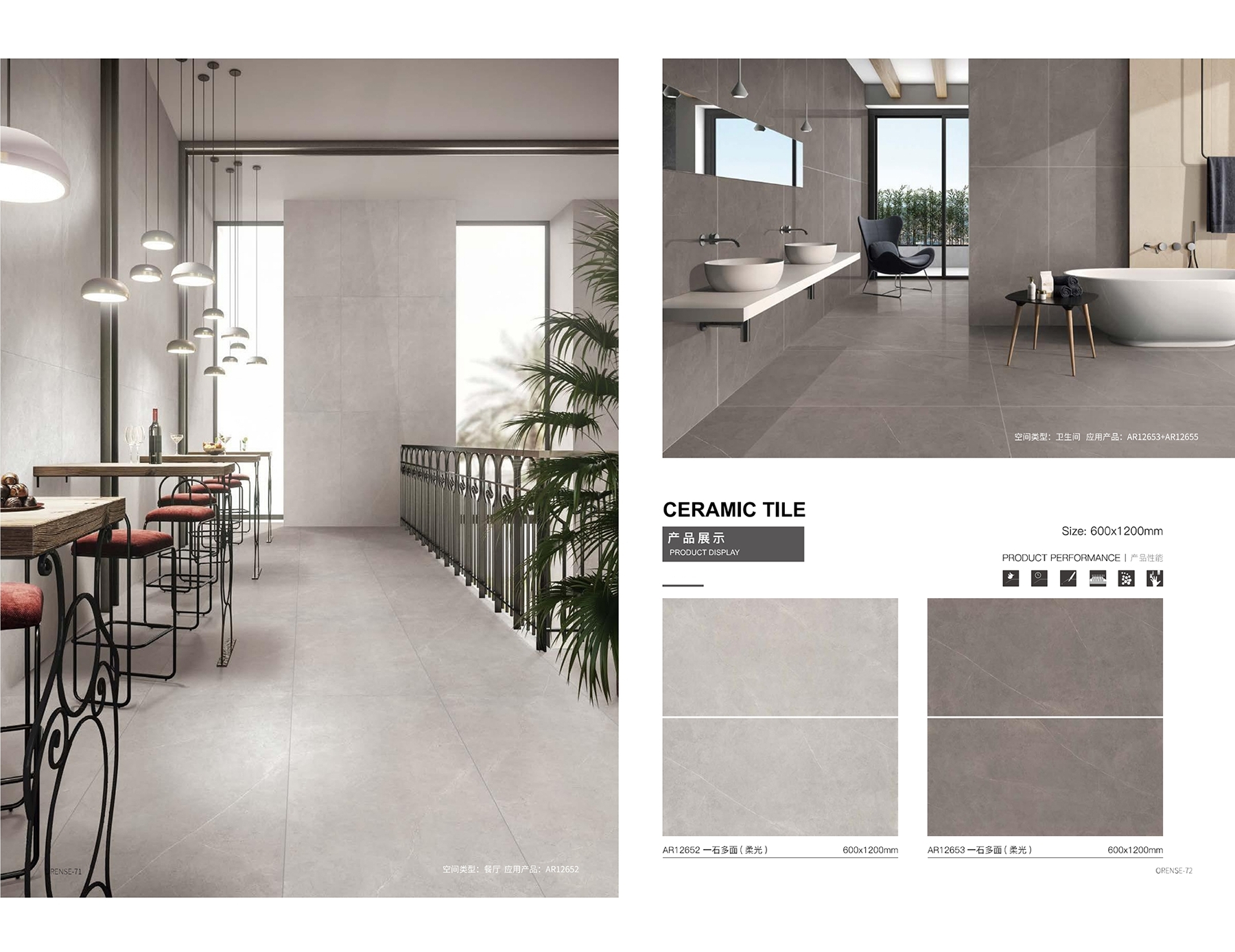

Sourcing building materials or furniture from China can save money and offer a wide range of options. However, many overseas buyers face a common and frustrating issue: “goods not matching the sample.” The sample may look really nice, but the actual shipment arrives with color variations, incorrect sizing, or even changed materials. These discrepancies can delay projects, increase costs, and create unnecessary conflicts.

Why does this happen then? For starters, communicating across borders isn’t always smooth. Whether it’s through words, emails, or photos, they can only tell part of the story. But small differences in interpretations can lead to big differences in the final product.

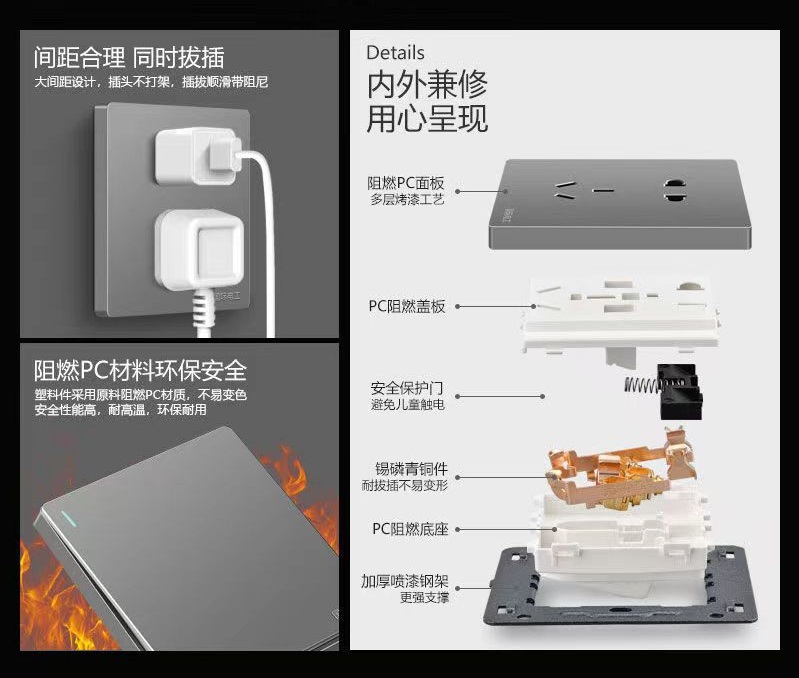

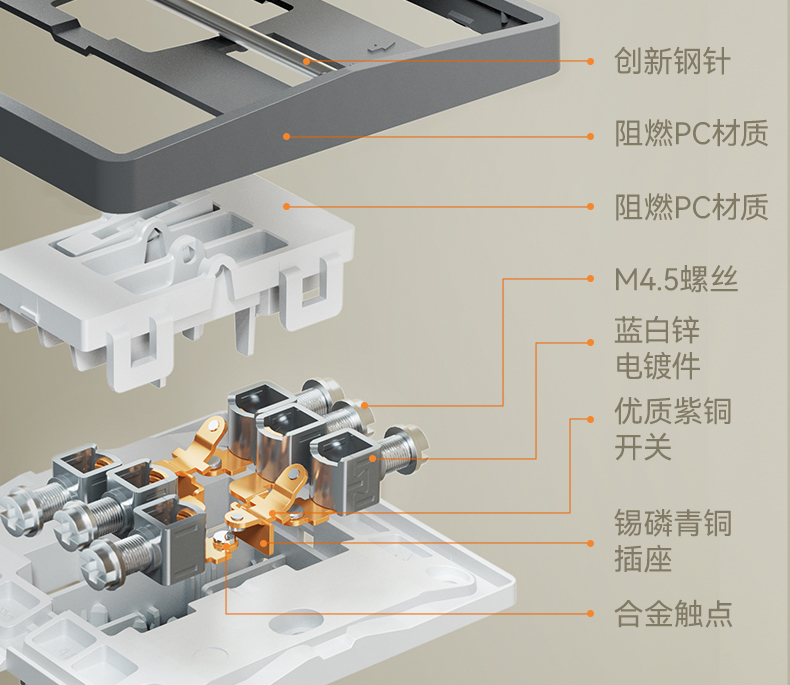

At the same time, without someone to check the progress, some factories might take shortcuts during mass production. Materials may get swapped. Quality may slip, or specifications get ignored. When no one inspects the goods before shipment, problems usually only come to light after the cargo arrives. And that would be too late to fix.

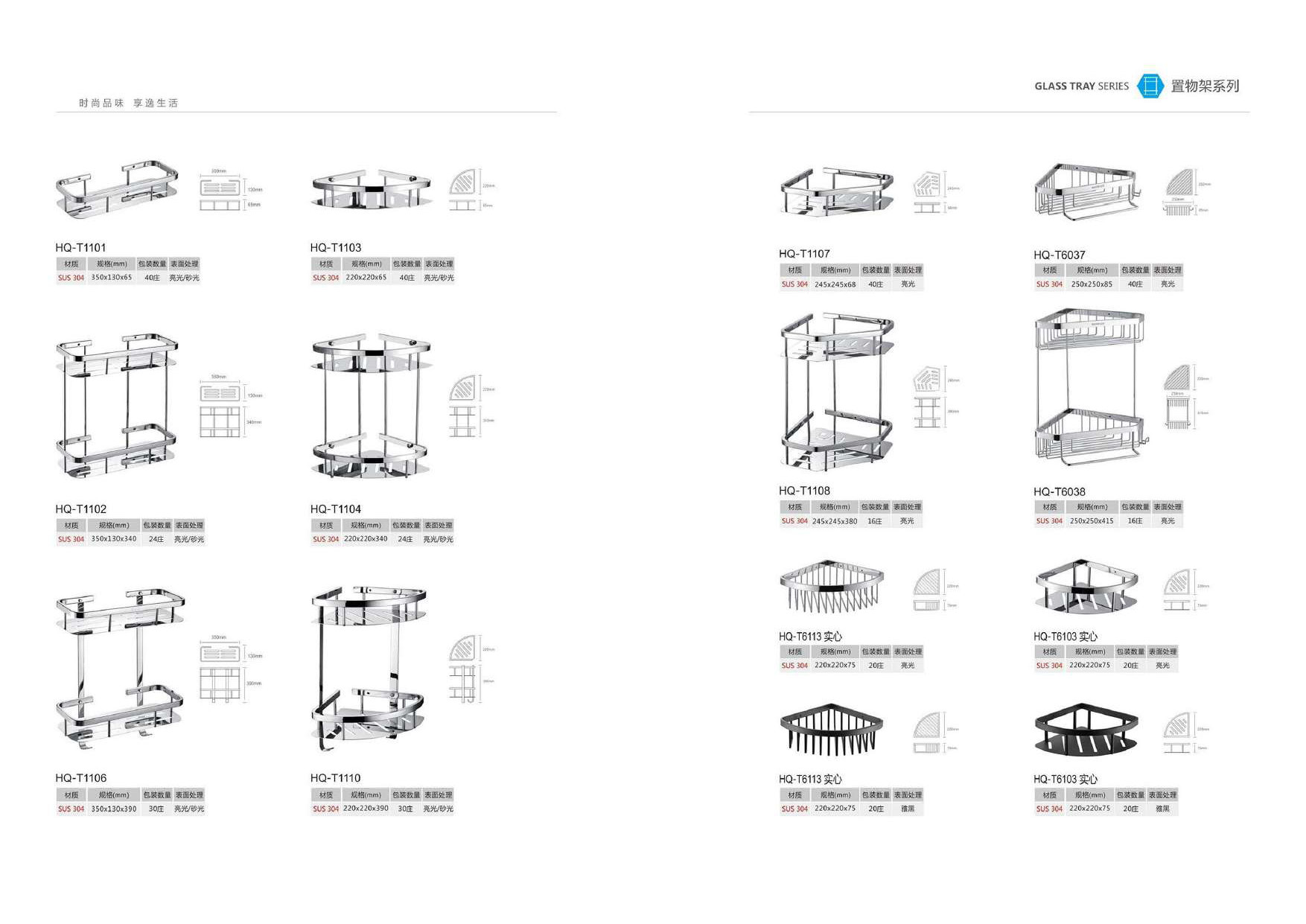

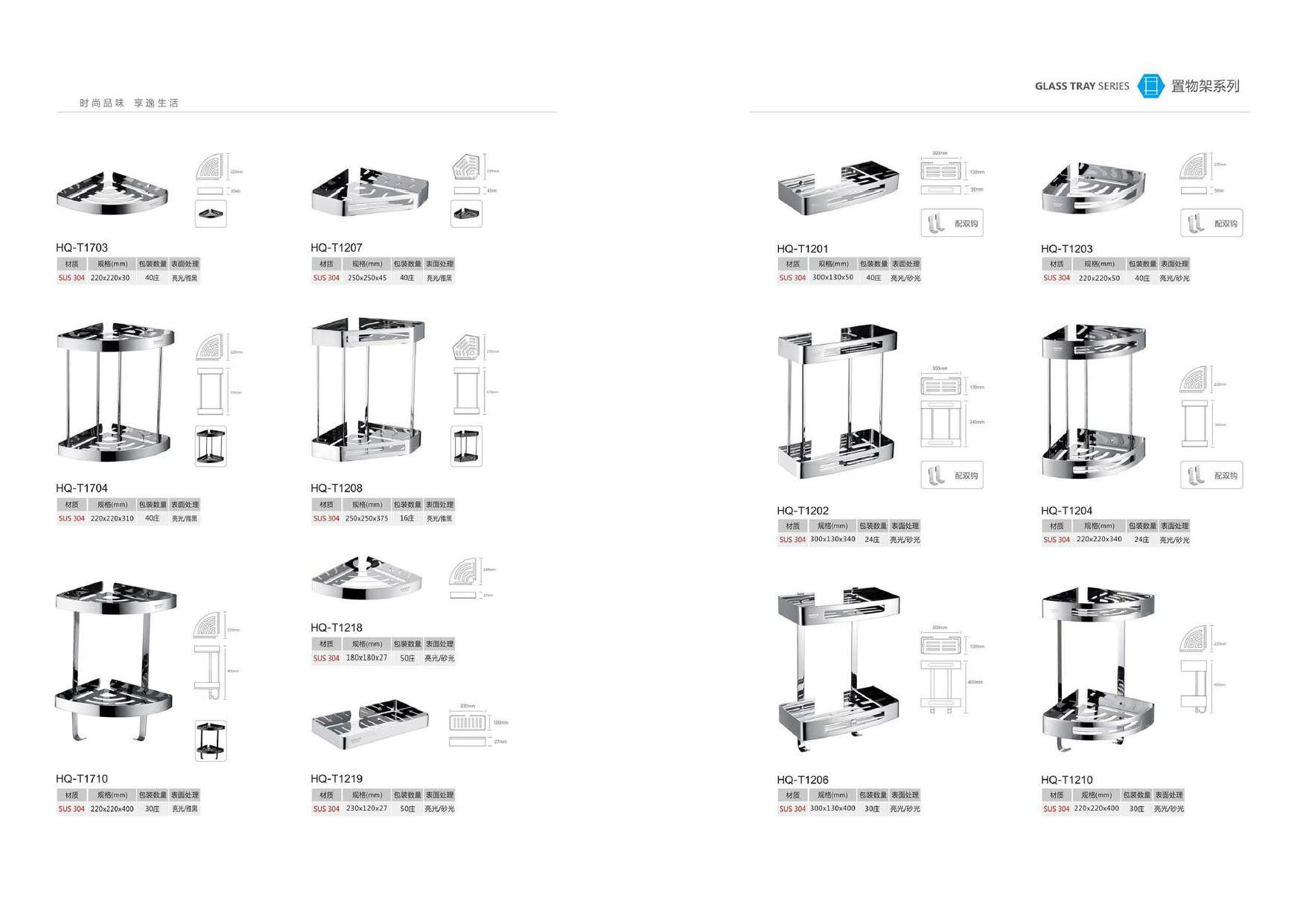

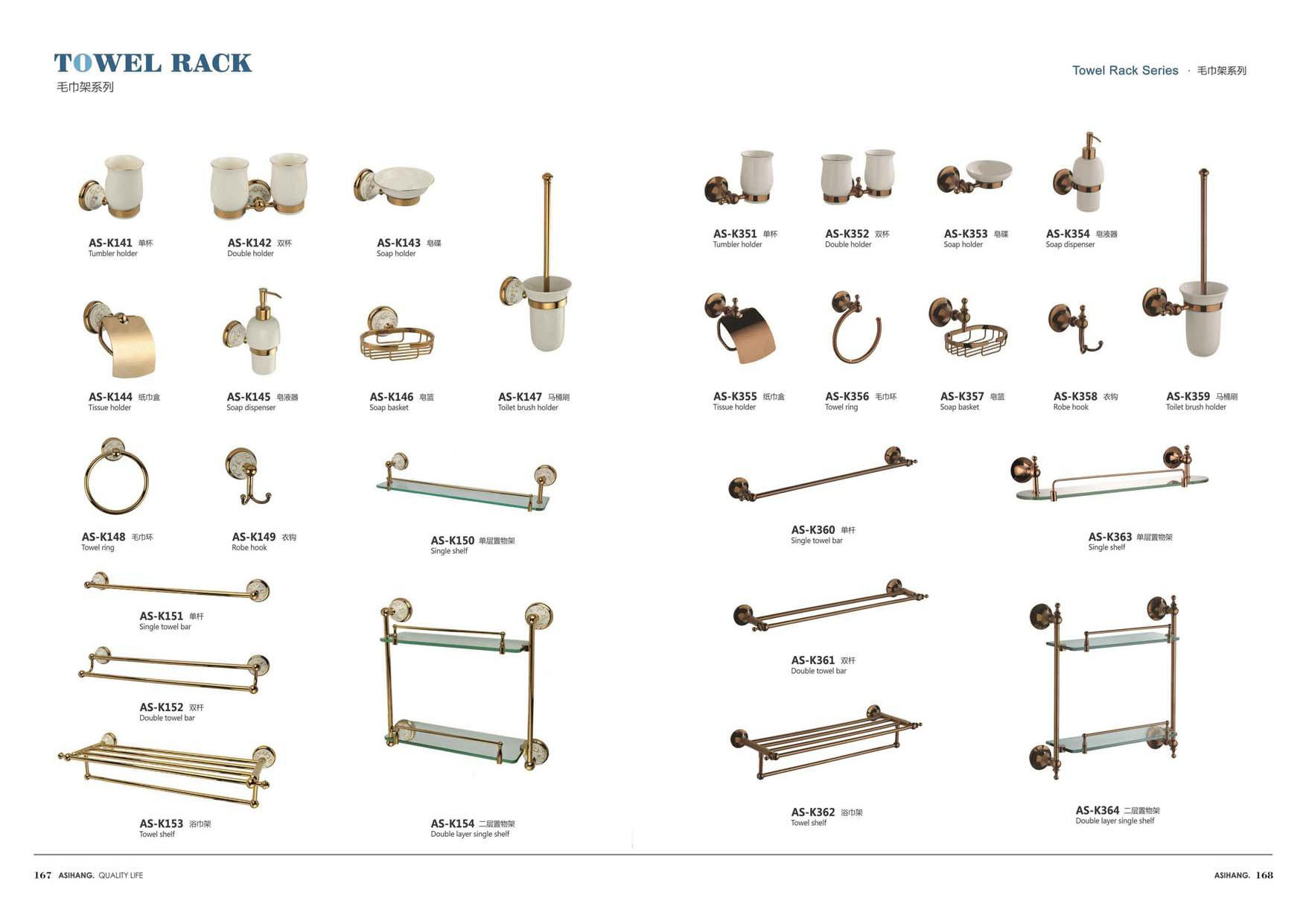

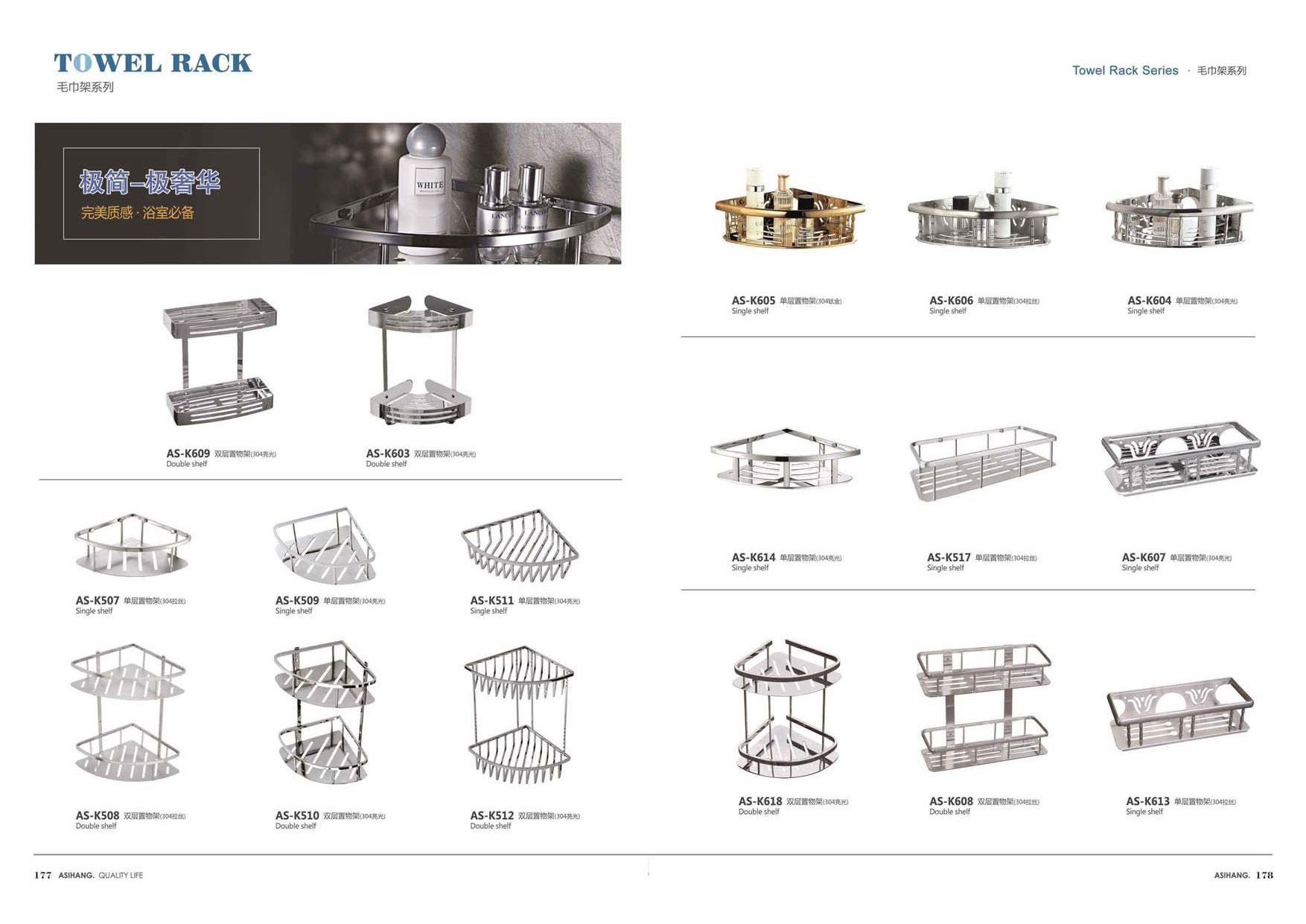

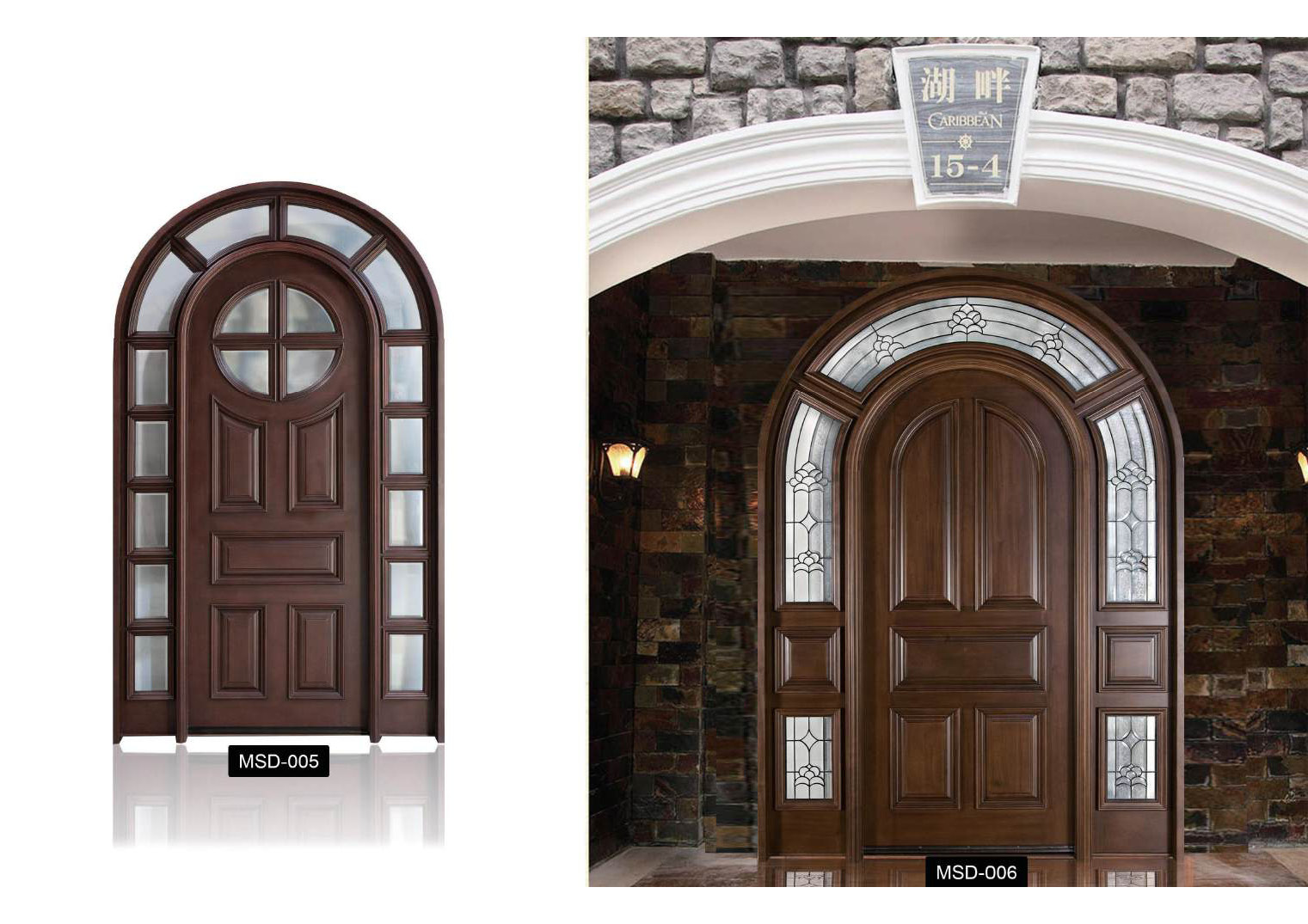

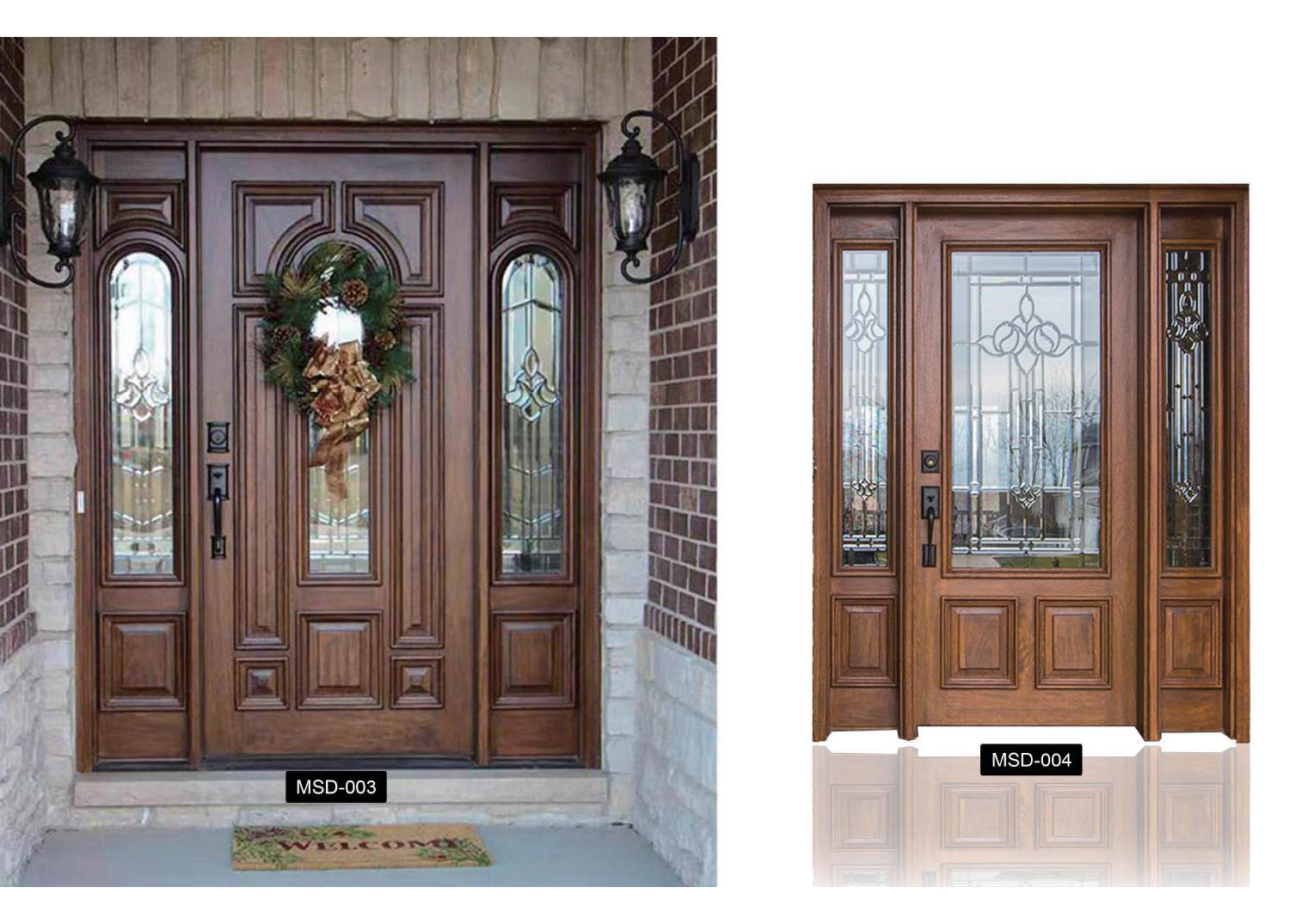

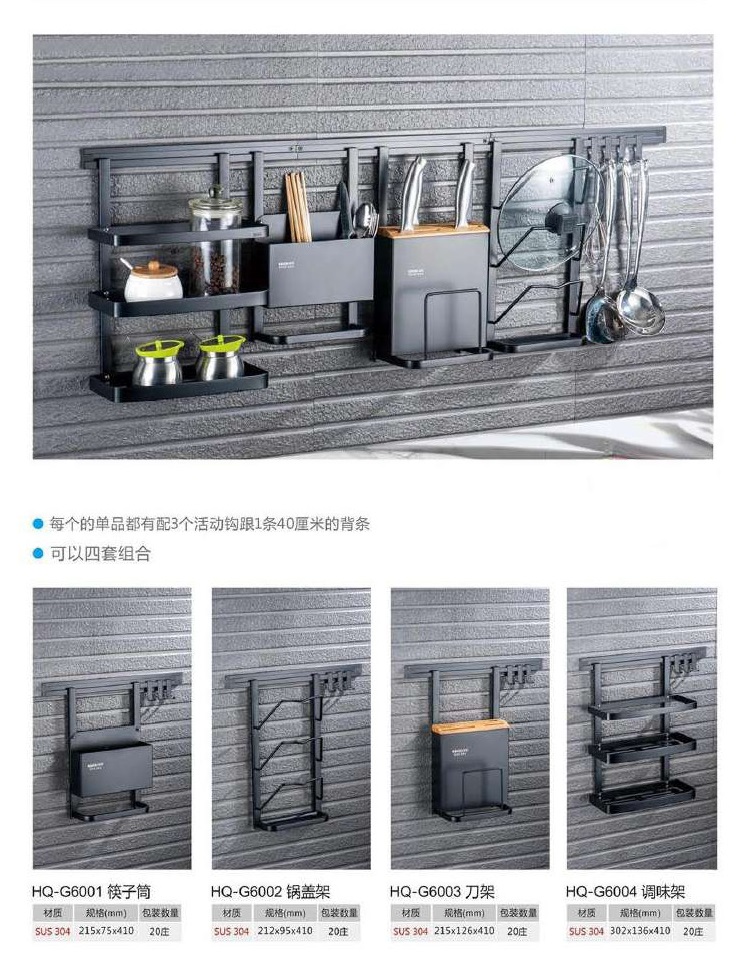

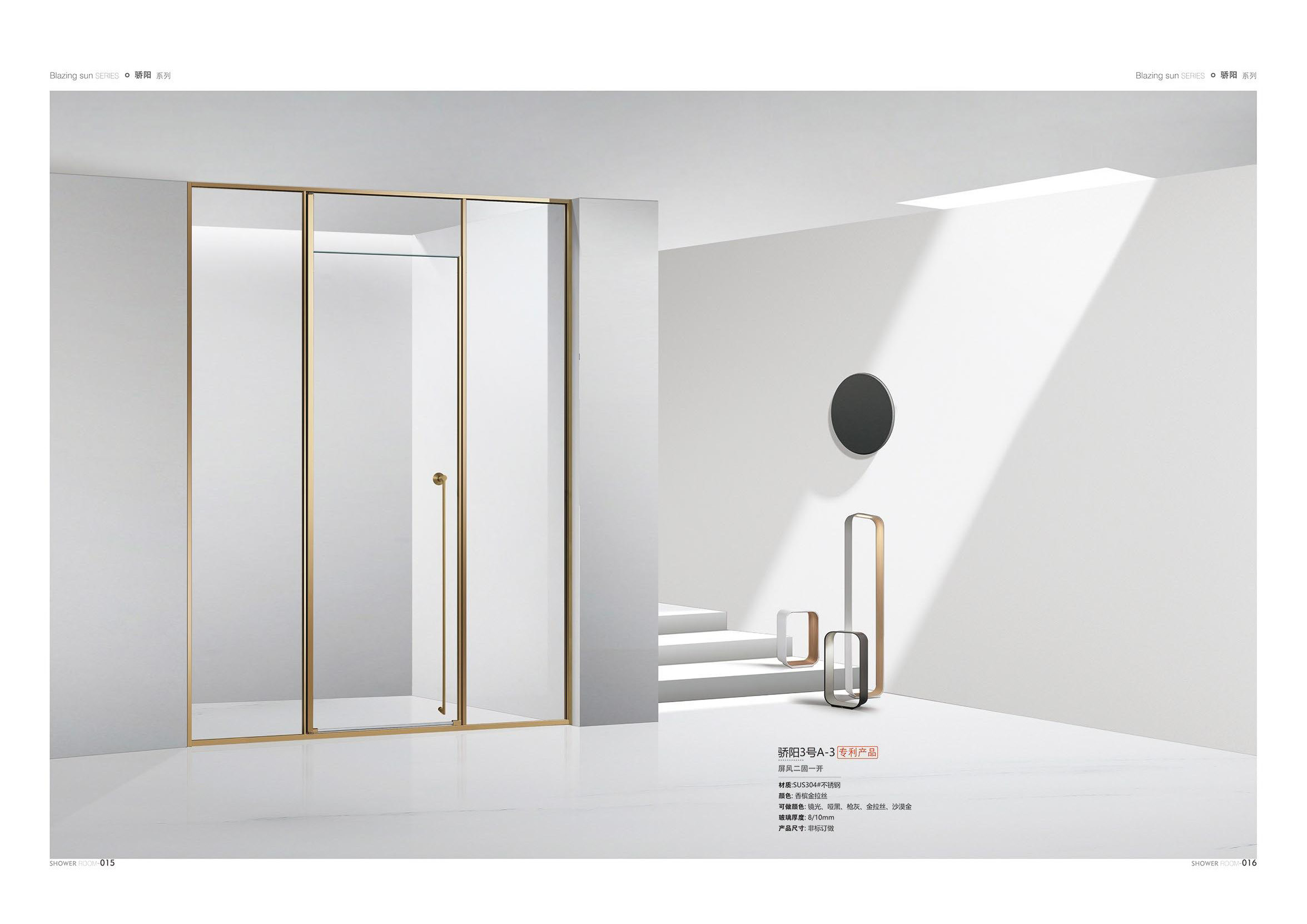

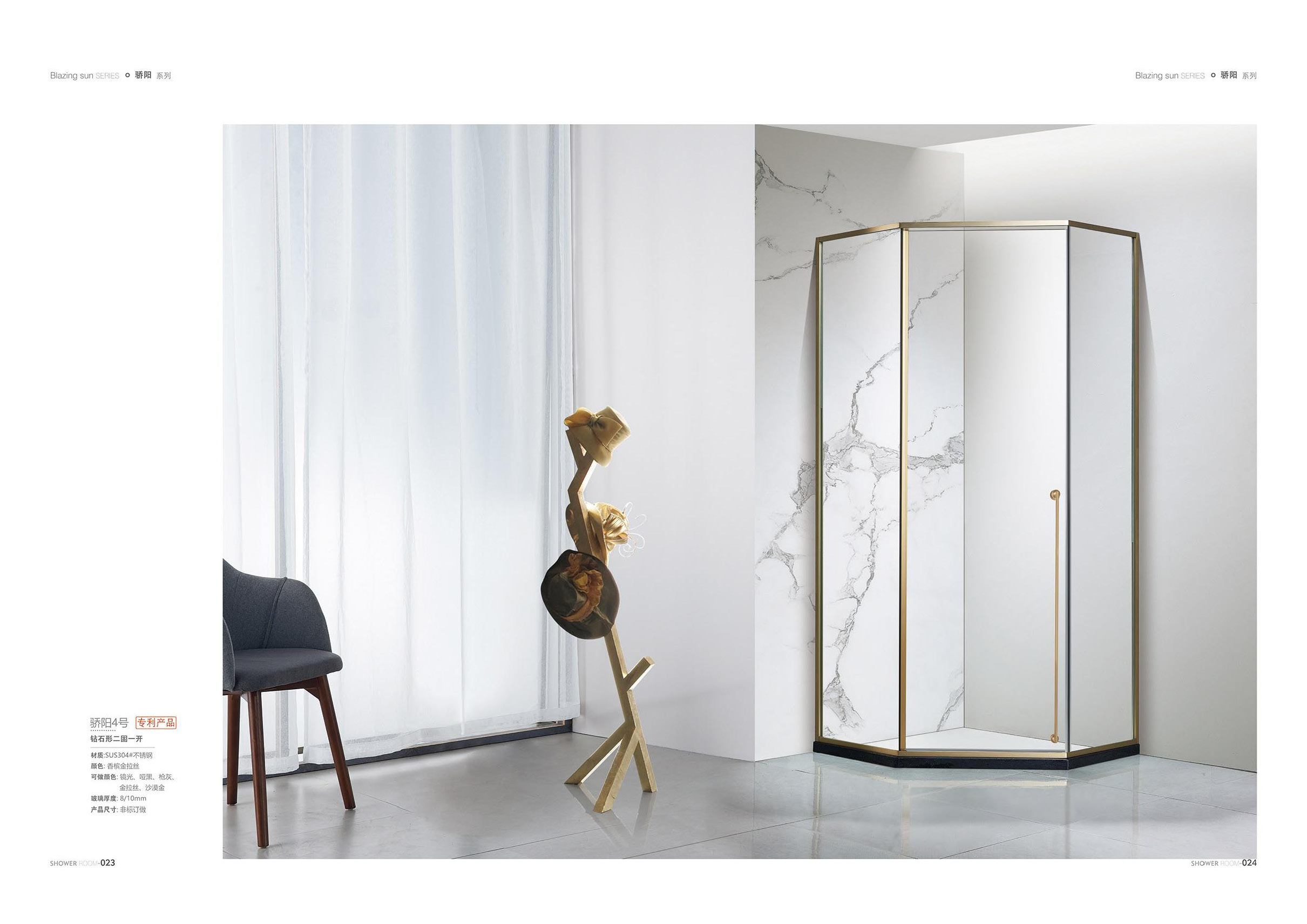

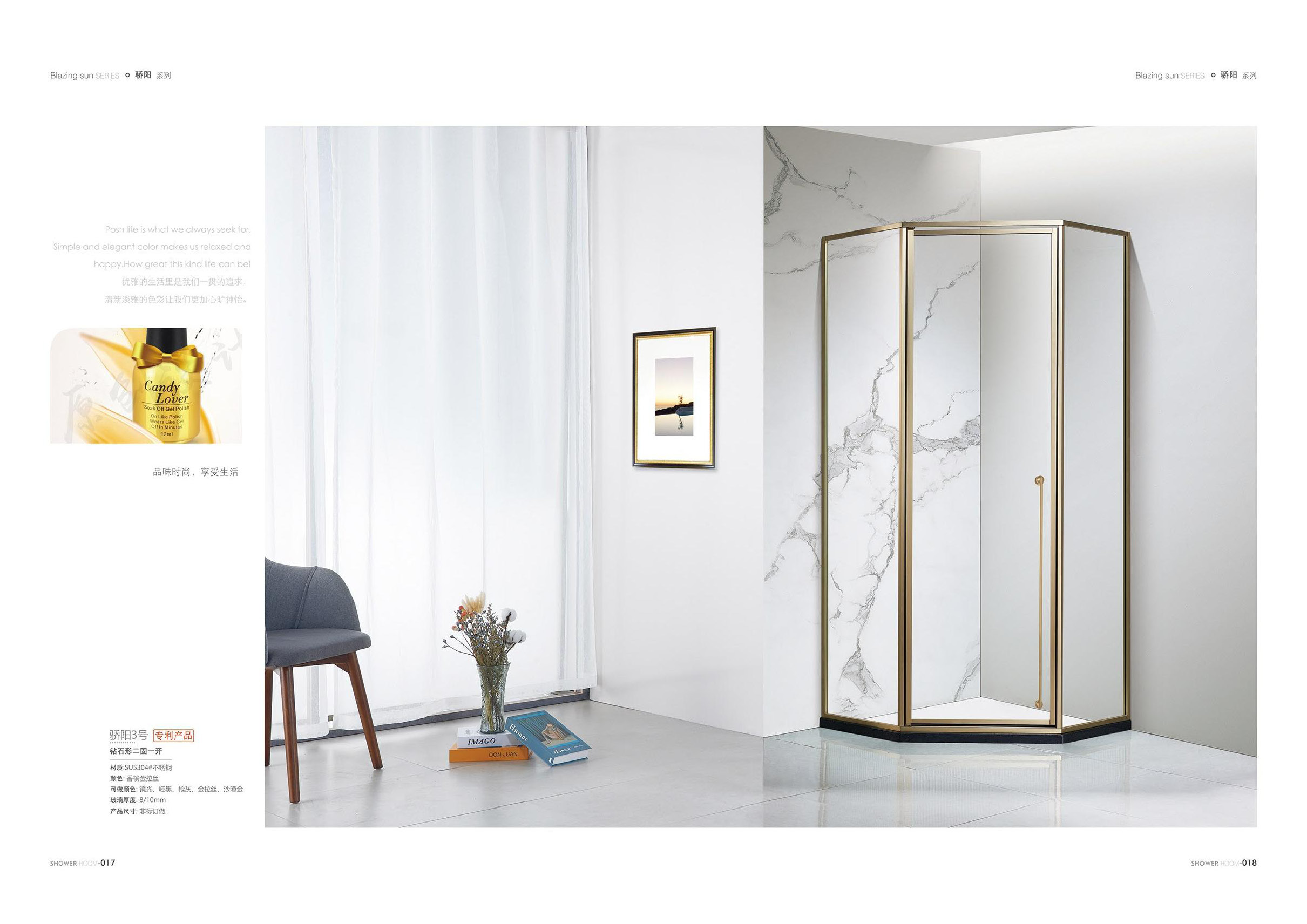

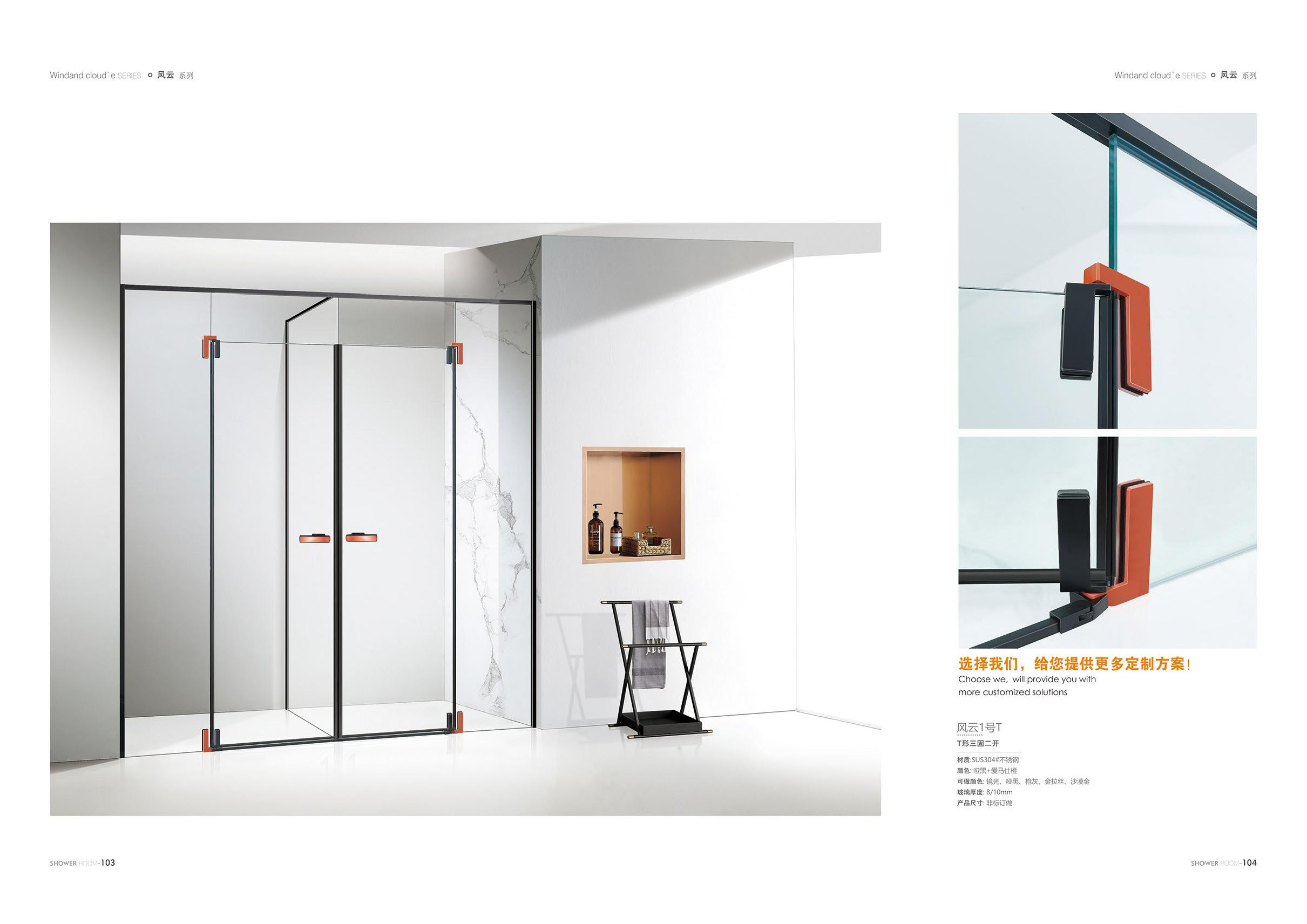

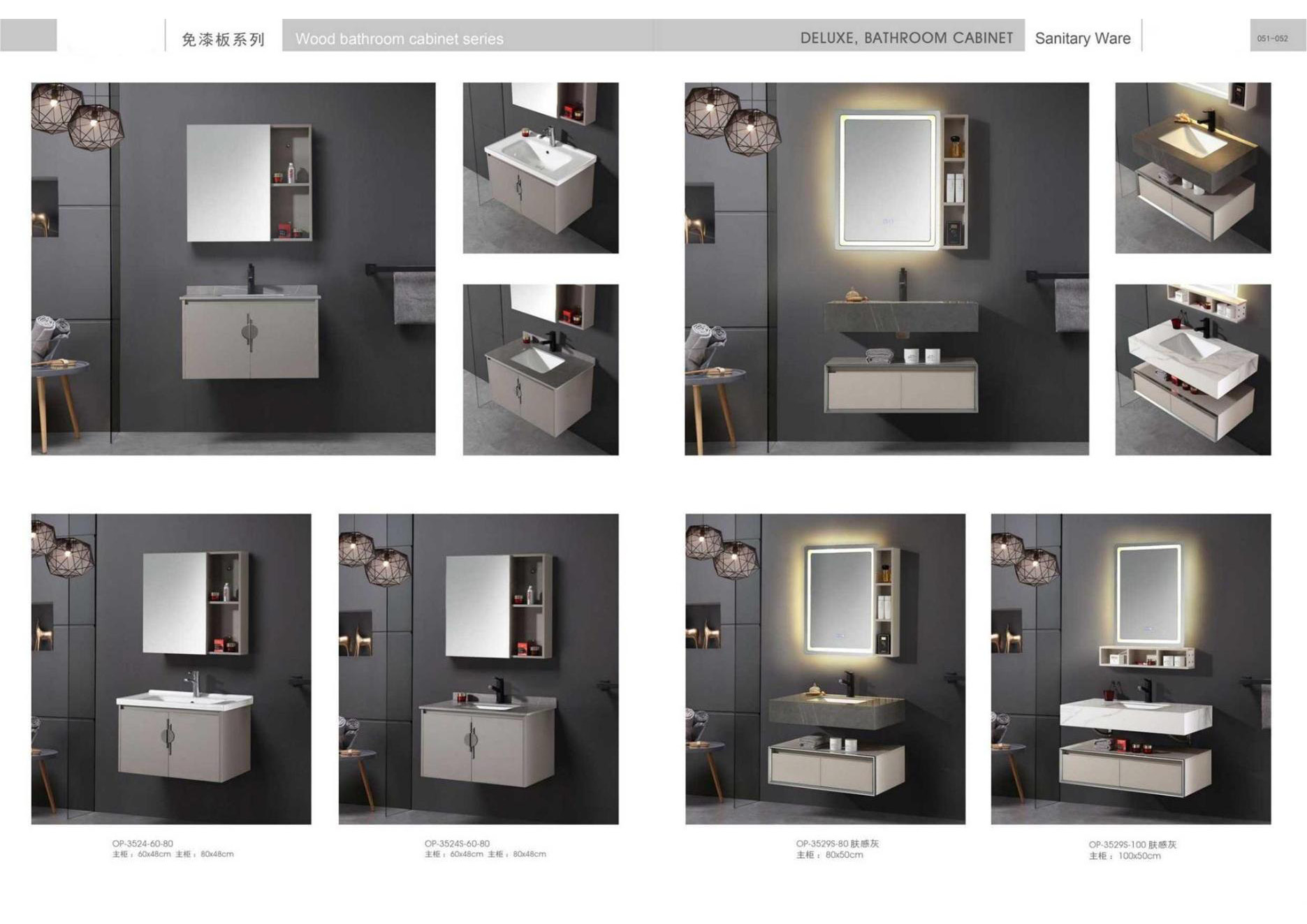

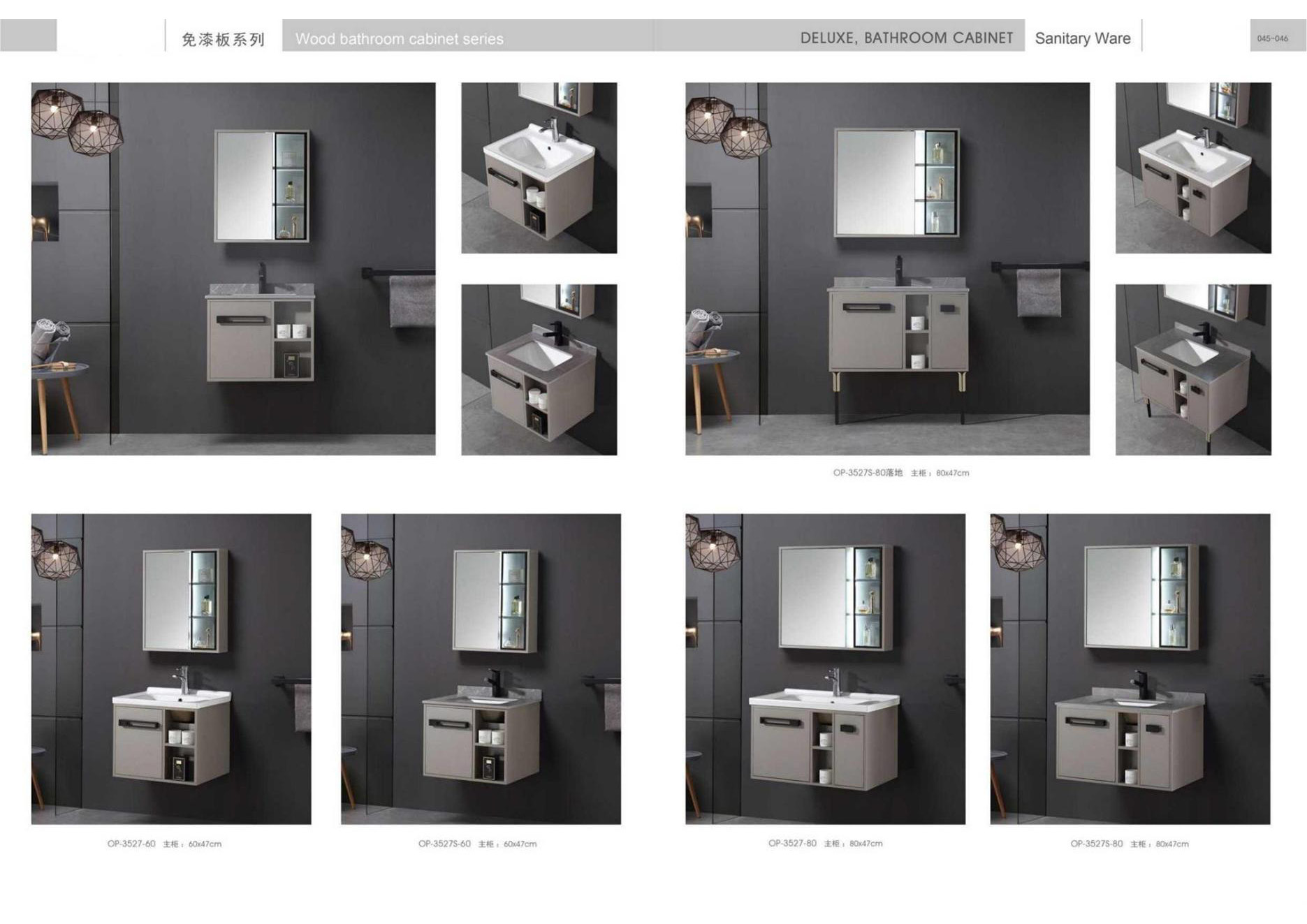

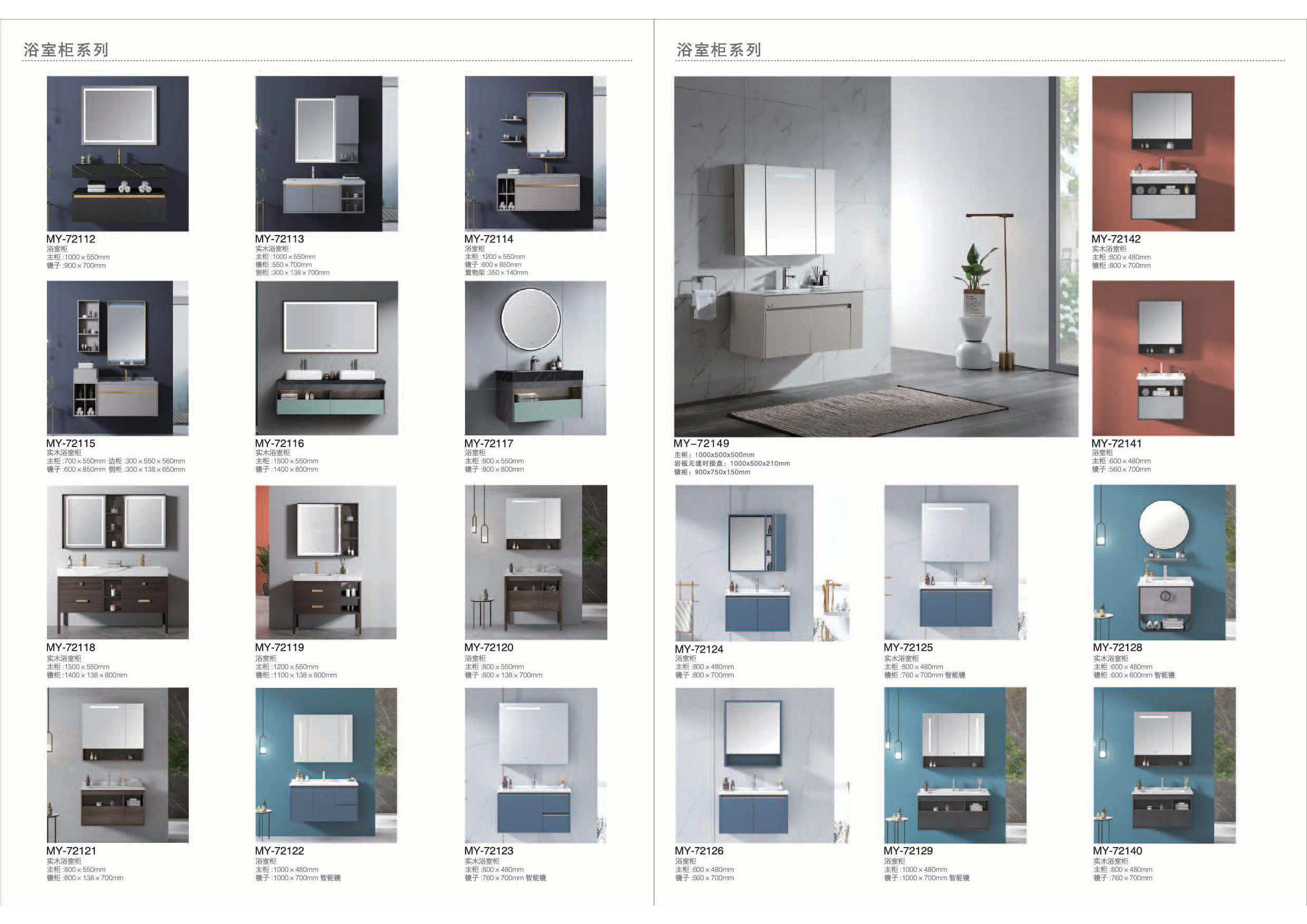

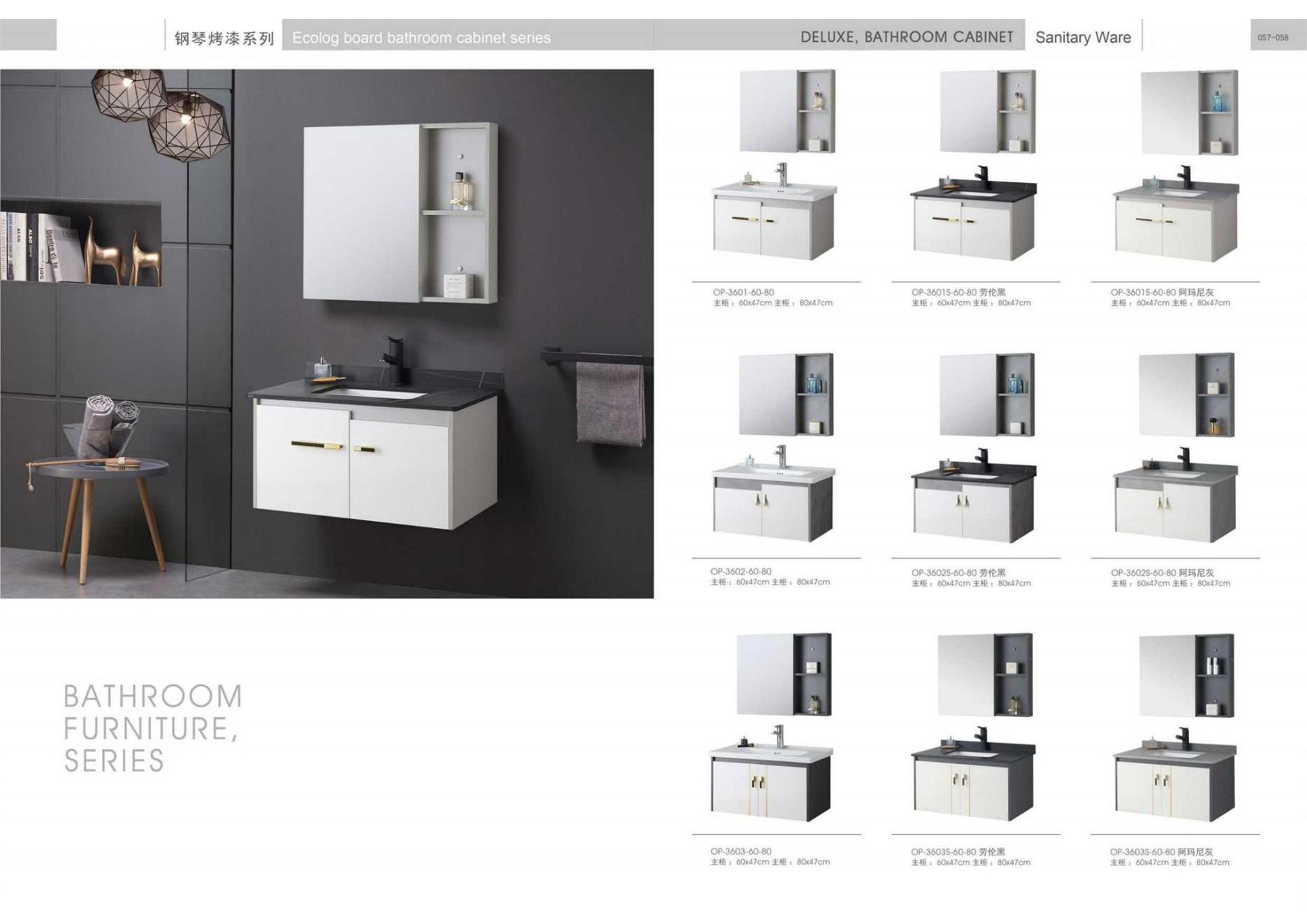

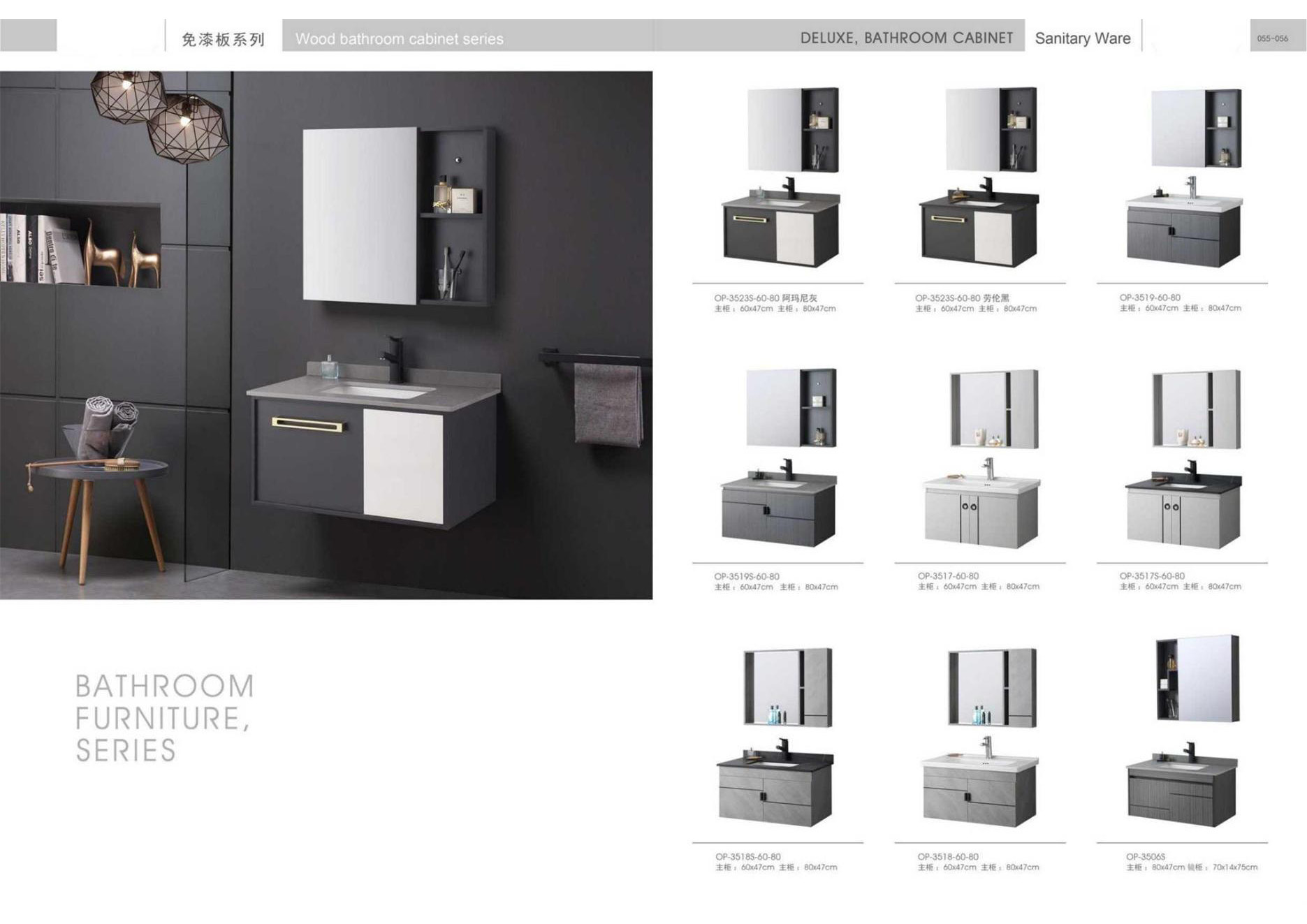

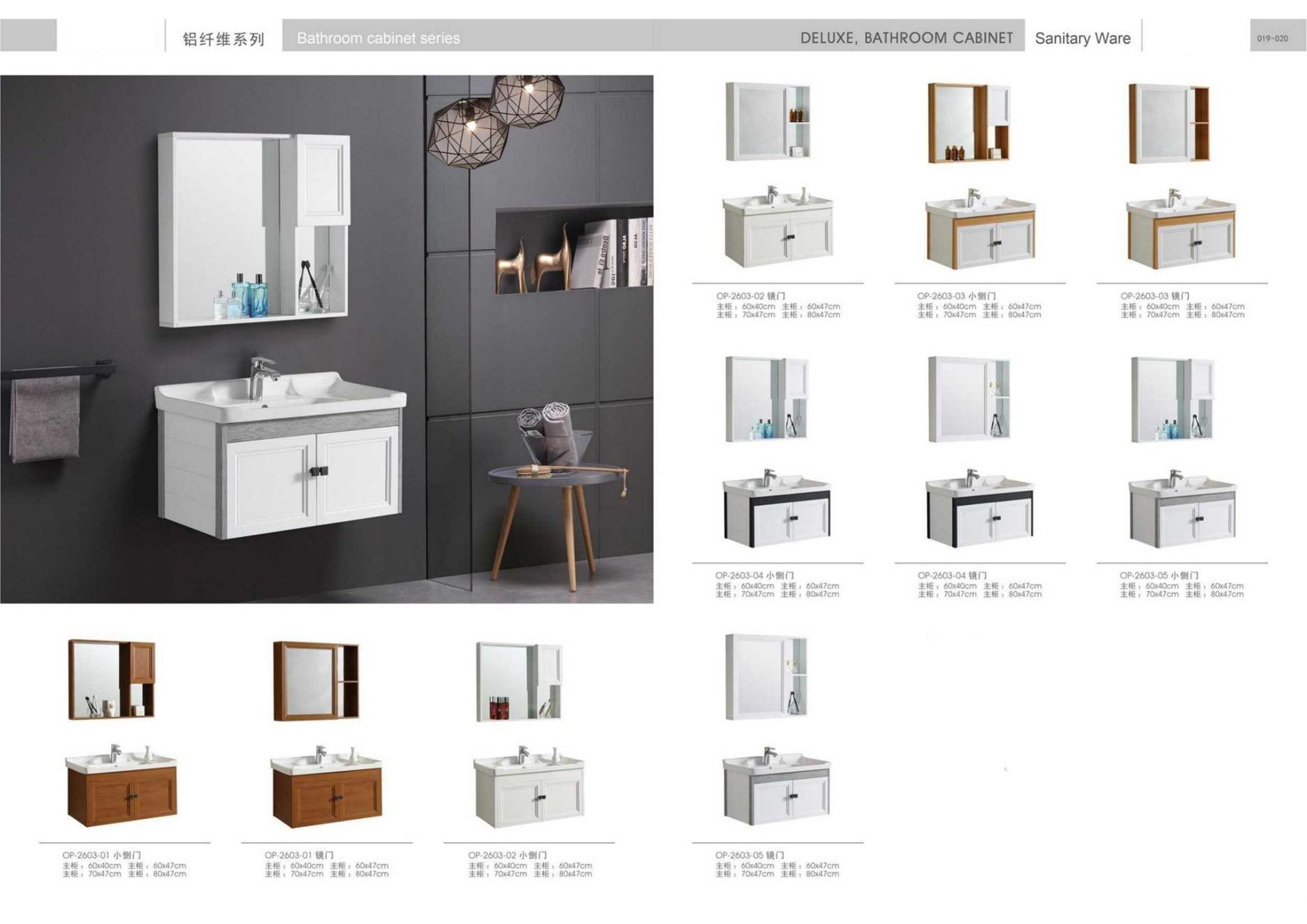

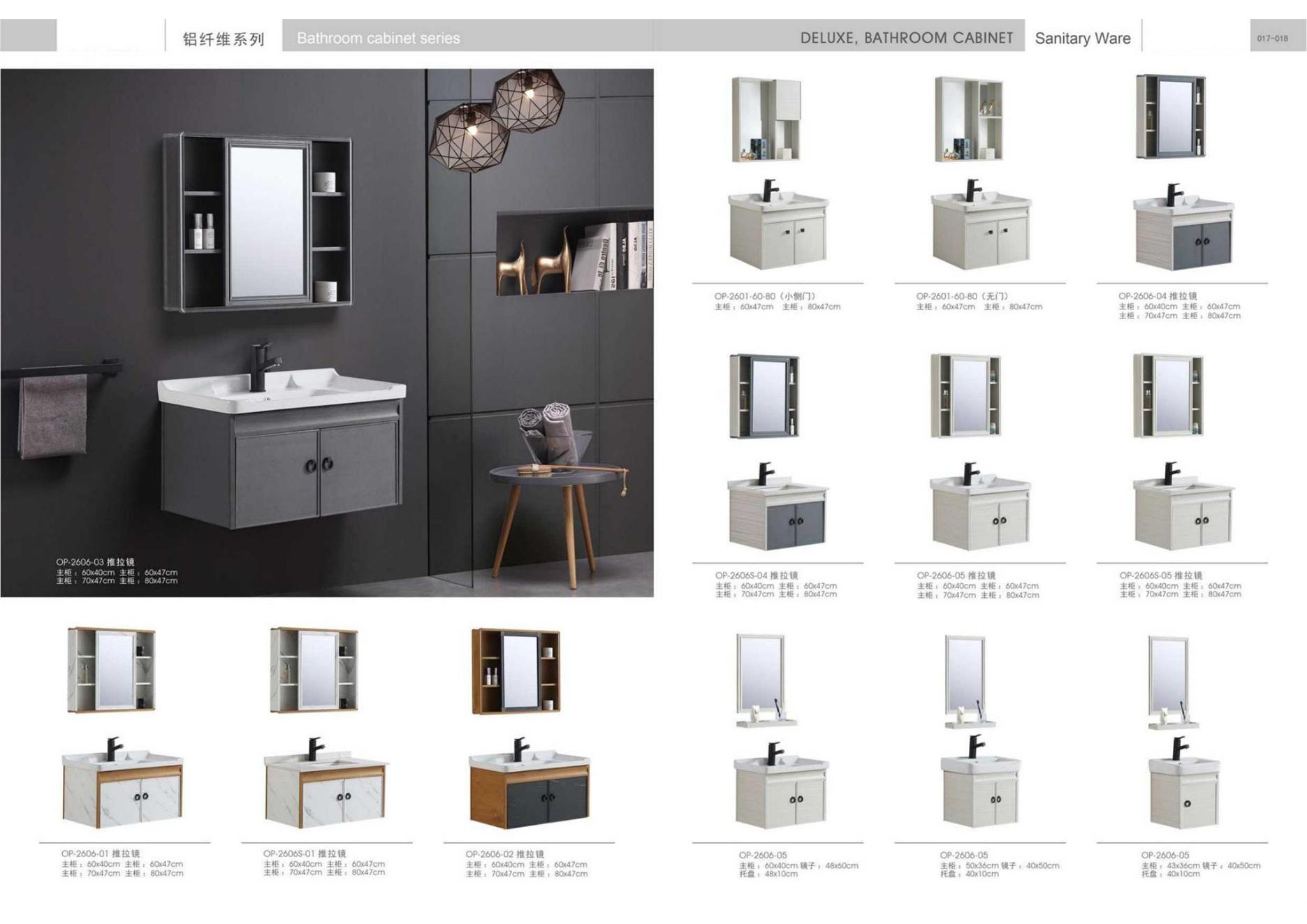

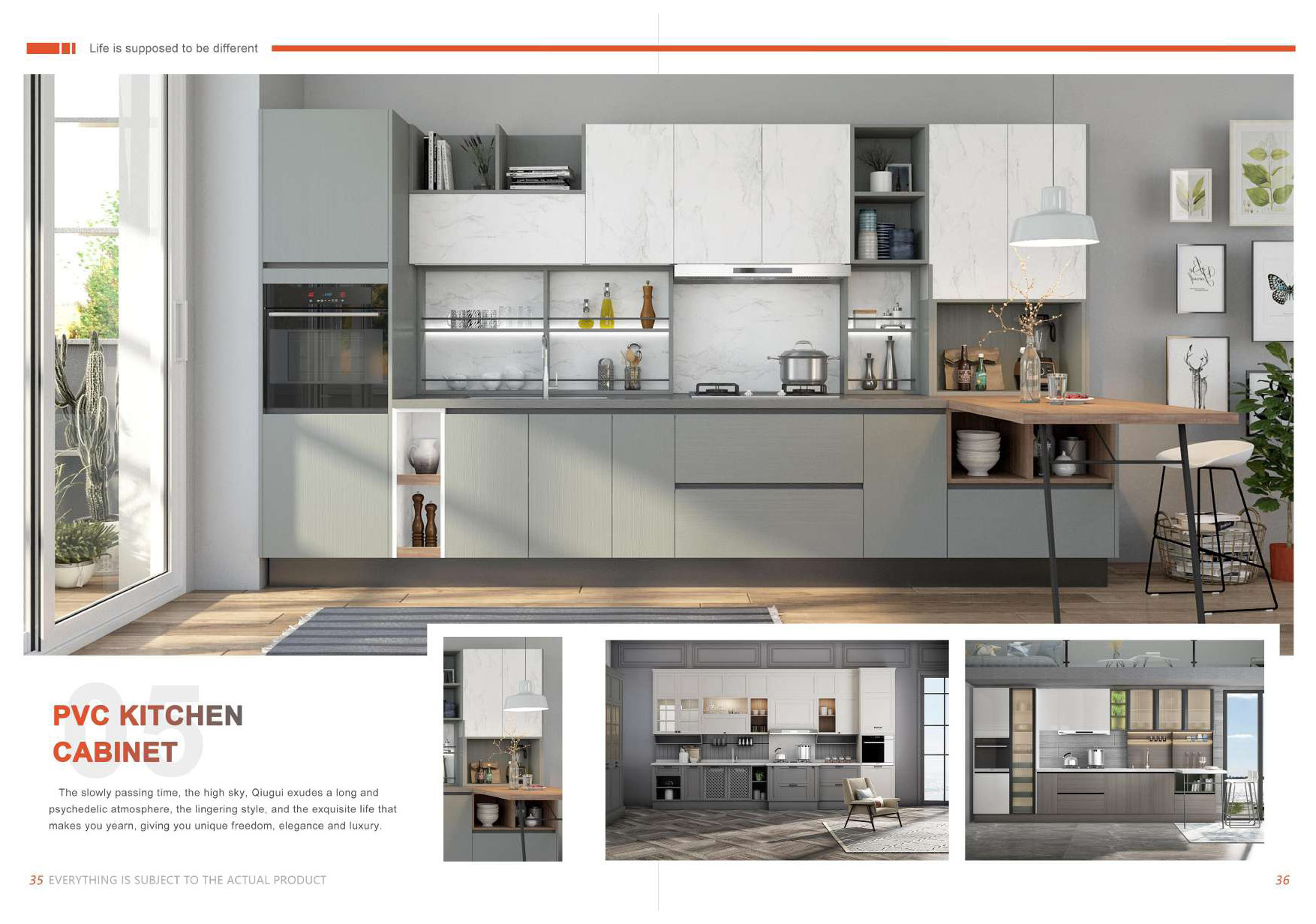

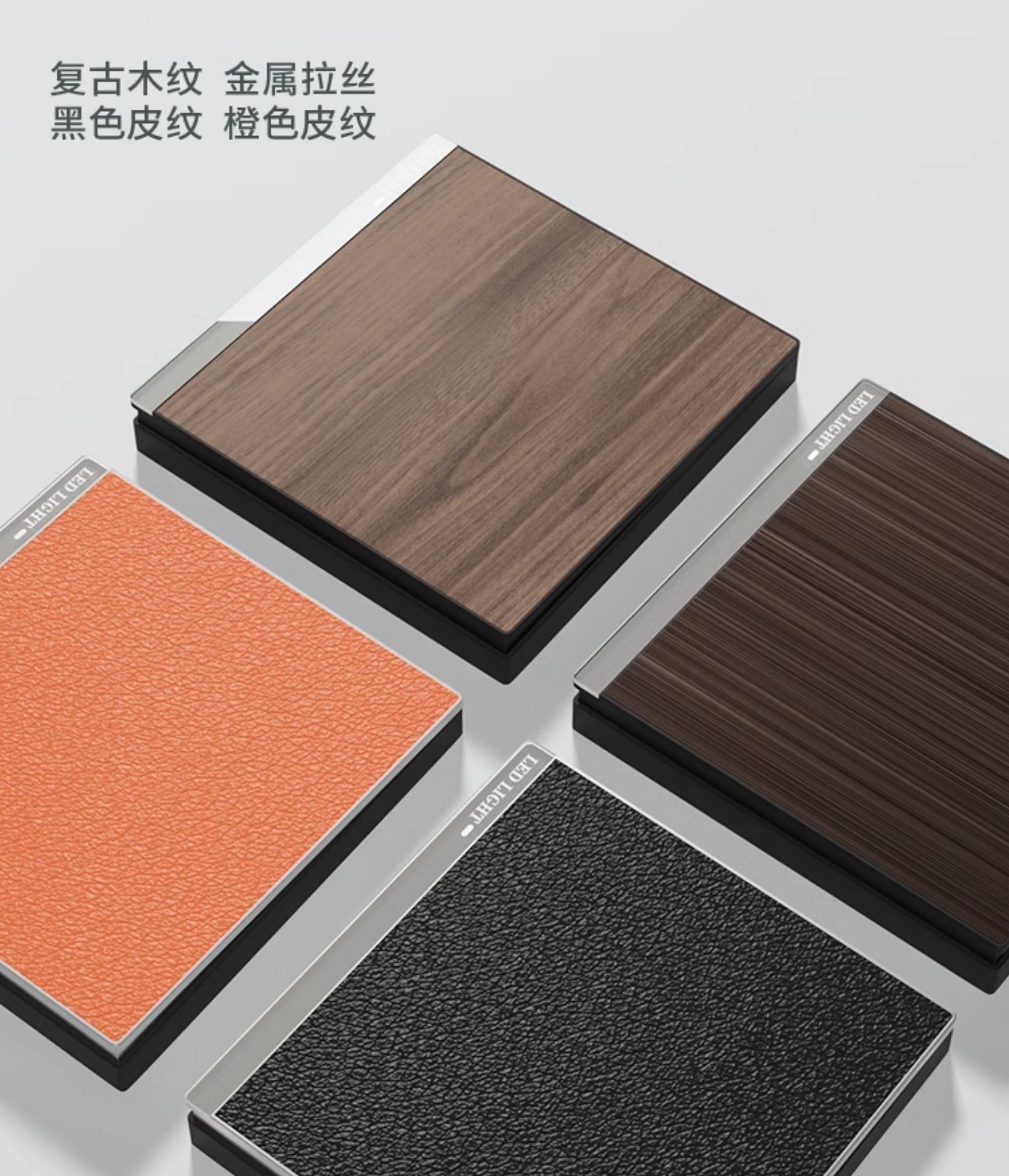

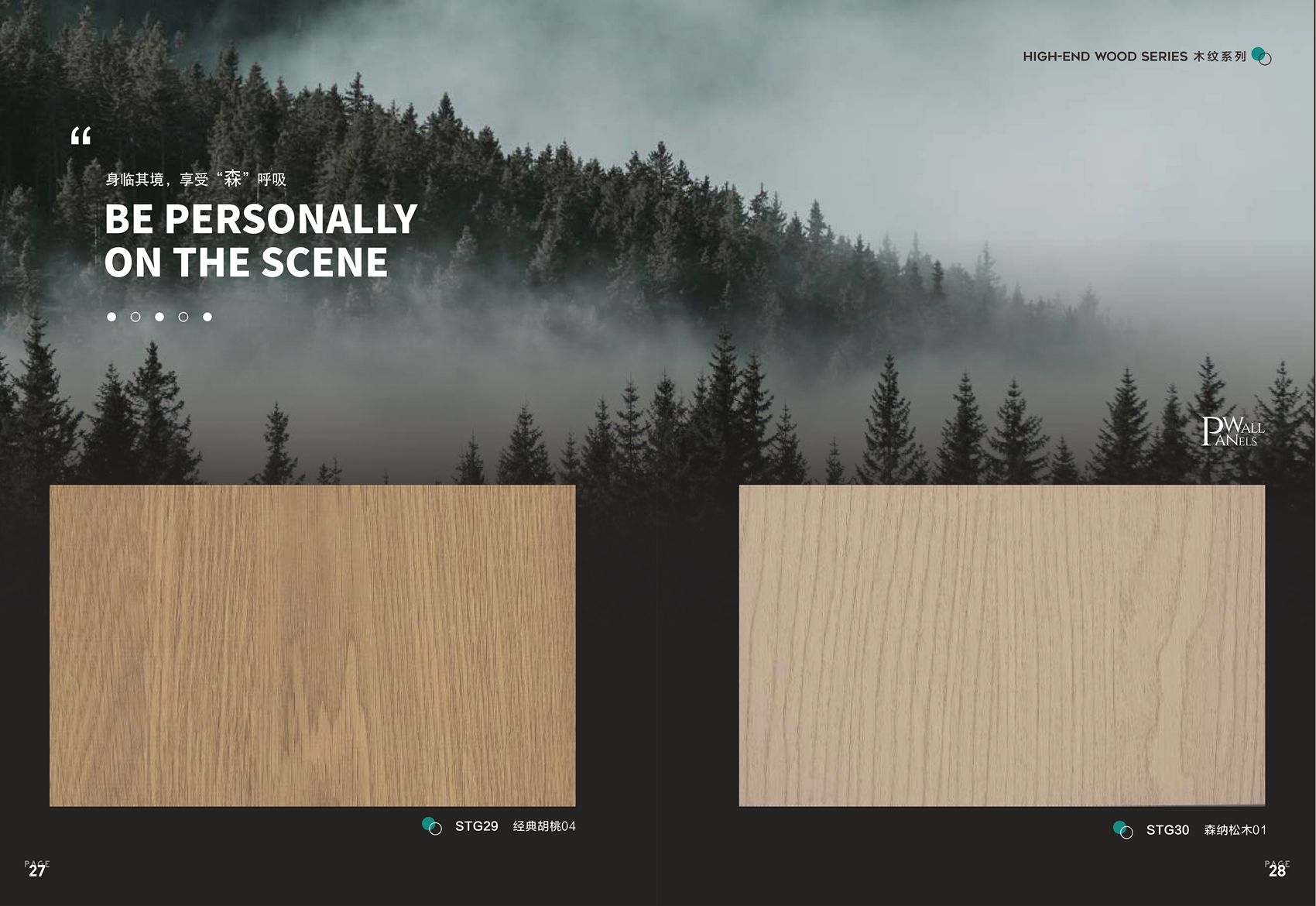

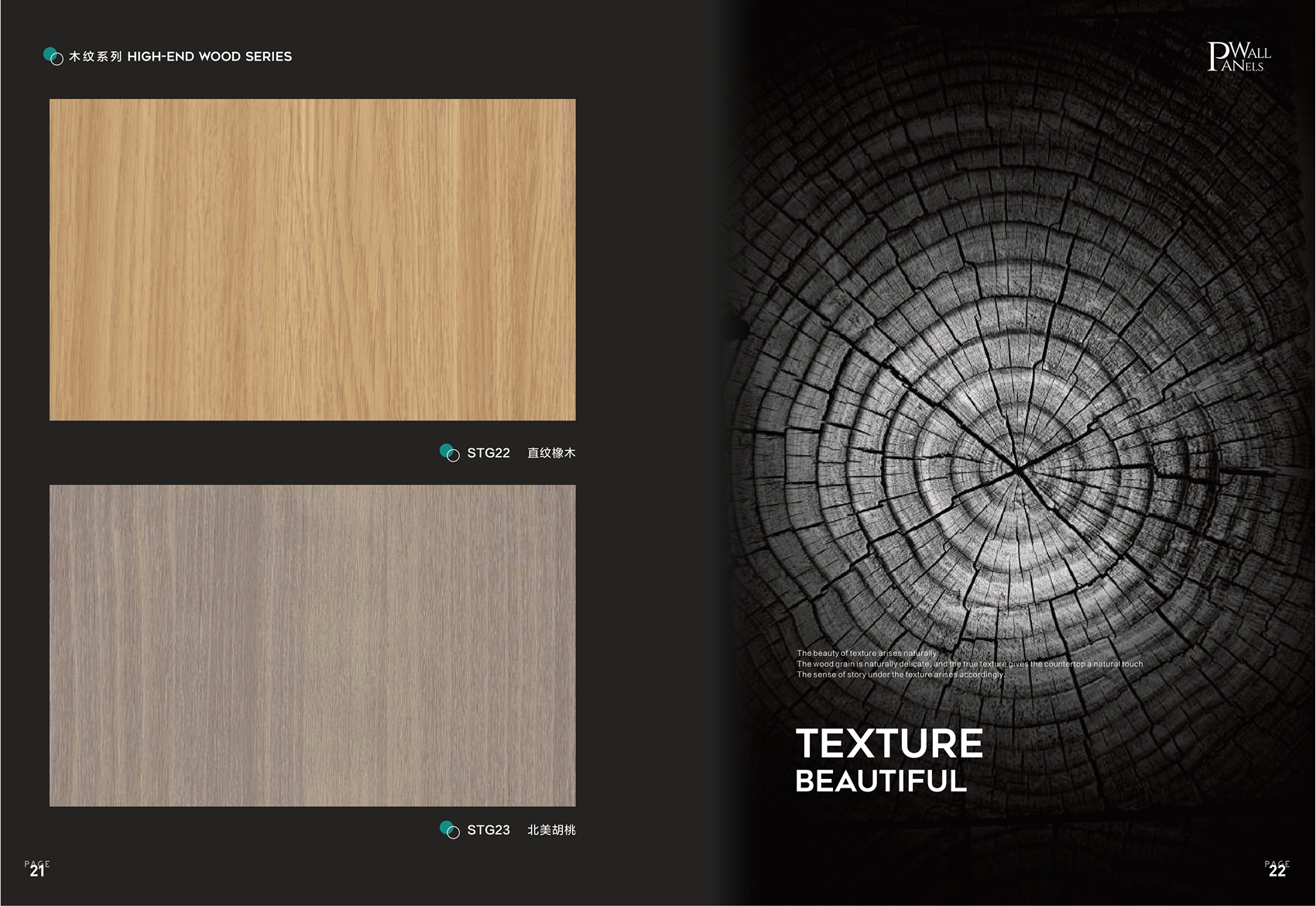

There are different solutions to tackle this problem. One of the most effective is to get involved in the product selection process yourself. We actually encourage our clients to come to China and visit suppliers to select the needed items in person. They can see the materials, check the finishes, and pick the samples.

As a professional sourcing agent, we fully support our clients visiting China for product selection. We’ll help arrange everything, including supplier visits, communication with suppliers, on-site translation, and travel logistics.

We don’t make decisions for you. We provide procurement support. You pick the products in person. We help make sure they’re made right. And the result is that you get the best protection against mismatched goods. And a smarter, smoother, and much more reliable procurement experience, too. Feel free to contact us for further details and service.